8.2 Handling faults

If there are deviations from normal operation or if faults occur, initially proceed according to the

following list. In this regard, observe the relevant chapters in the documentation associated with

the components of the complete drive system.

WARNING

Risk to life as a result of non-functioning protective devices

Protective devices that are not functioning can result in death, serious injury or material

damage.

• Do not deactivate protective devices. This also applies to test operation.

• Only work with protective devices that are fully functional.

NOTICE

Damage to the machine caused by faults

• Resolve the cause of the fault as specied in the remedial measures section.

• Repair damage to the machine.

• Replace the damaged motors.

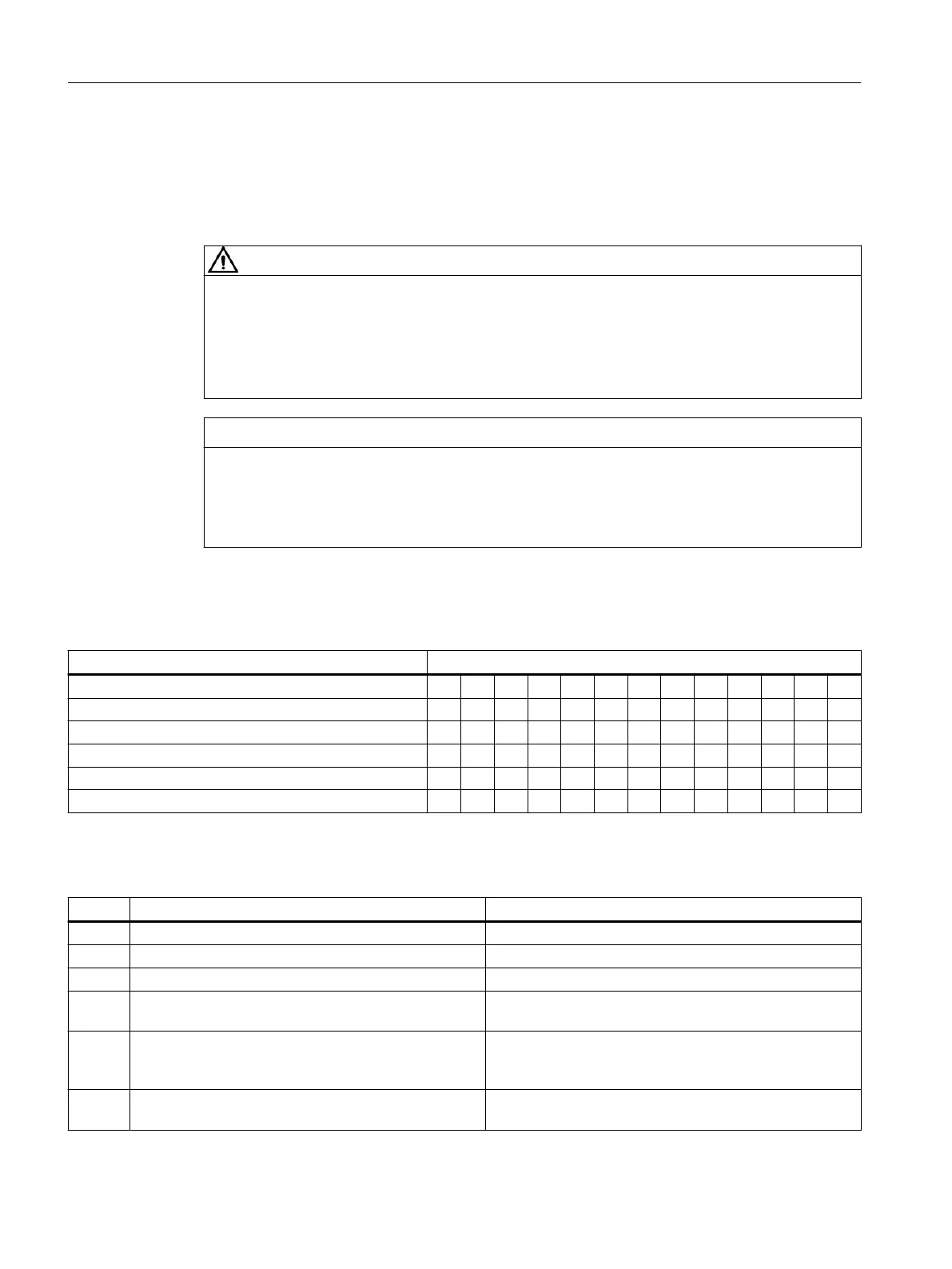

Table 8-1 Possible faults

Fault Origin of disturbance (according to the following table)

Motor blocked A B C D

Noise during operation D E K

High temperature rise during no-load operation D

High temperature rise when under load A D

Uneven running H J

Axis is sluggish E K L

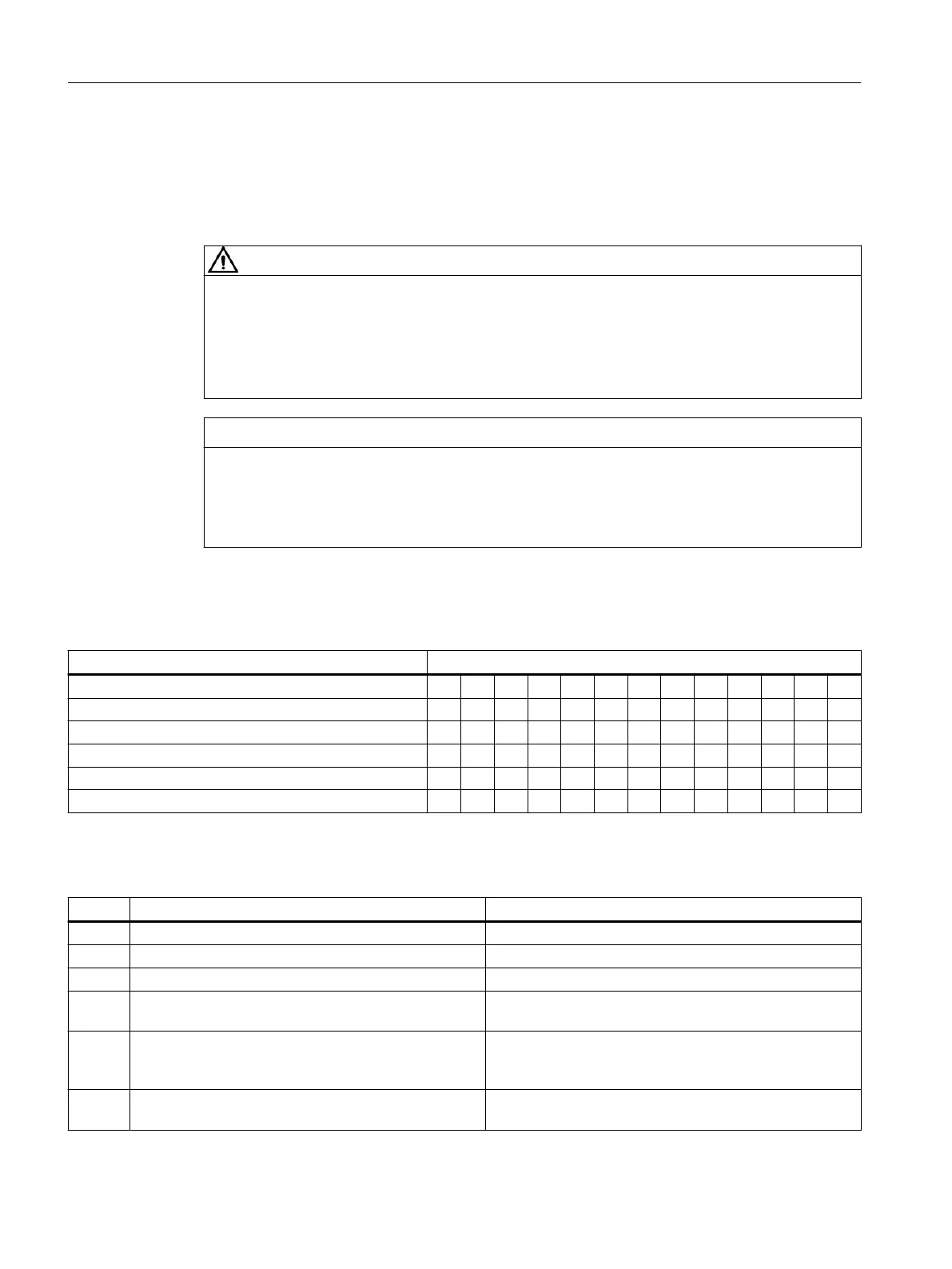

Table 8-2 Key to causes of faults and remedial measures

No. Cause of fault How to remedy the problem

A Overloading Reduce load

B Interrupted phase in the supply cable Check frequency converter and supply cables

C Interrupted phase in the supply cable after switching on Check frequency converter and supply cables

D Motor commutation is faulty Check the commutation, if required re-adjust the commu‐

tation angle oset

E Winding short-circuit or phase short-circuit in the pri‐

mary section winding

Measure the winding resistances and insulation resistan‐

ces, motor replacement after consultation with the manu‐

facturer

H Insucient grounding of the motor and/or encoder ca‐

ble

Check the grounding

Operation

8.2Handling faults

Naturally-Cooled 1FN3 Linear Motors

106 Operating Instructions, 06/2023, A5E52220465B AB

Loading...

Loading...