5.2 Specications for mounting linear motors

Mounting system

The following specications apply when mounting primary sections and secondary sections to

the machine:

• Use M5 screws with property class 10.9. (friction value μ

tot

=0.1).

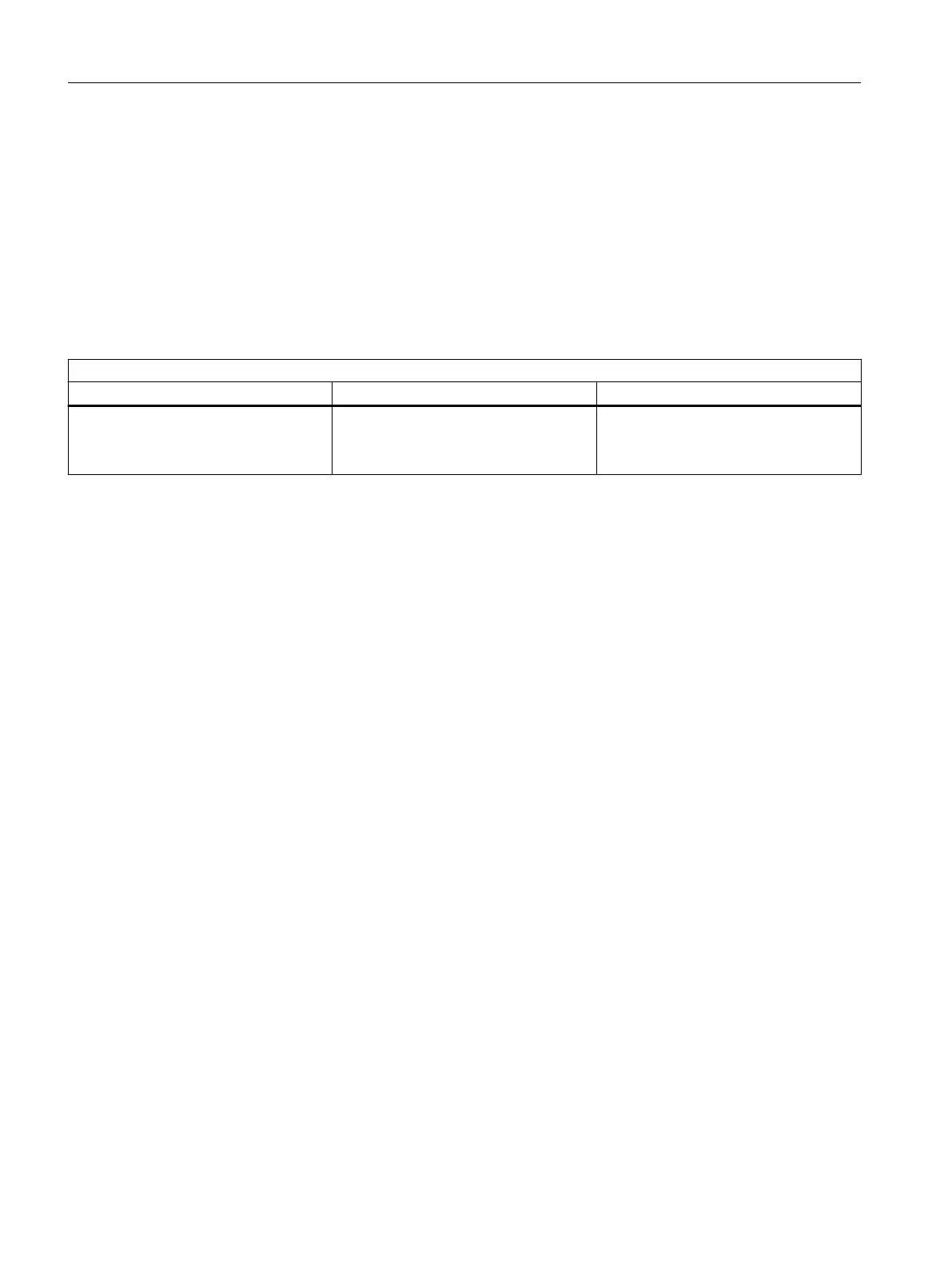

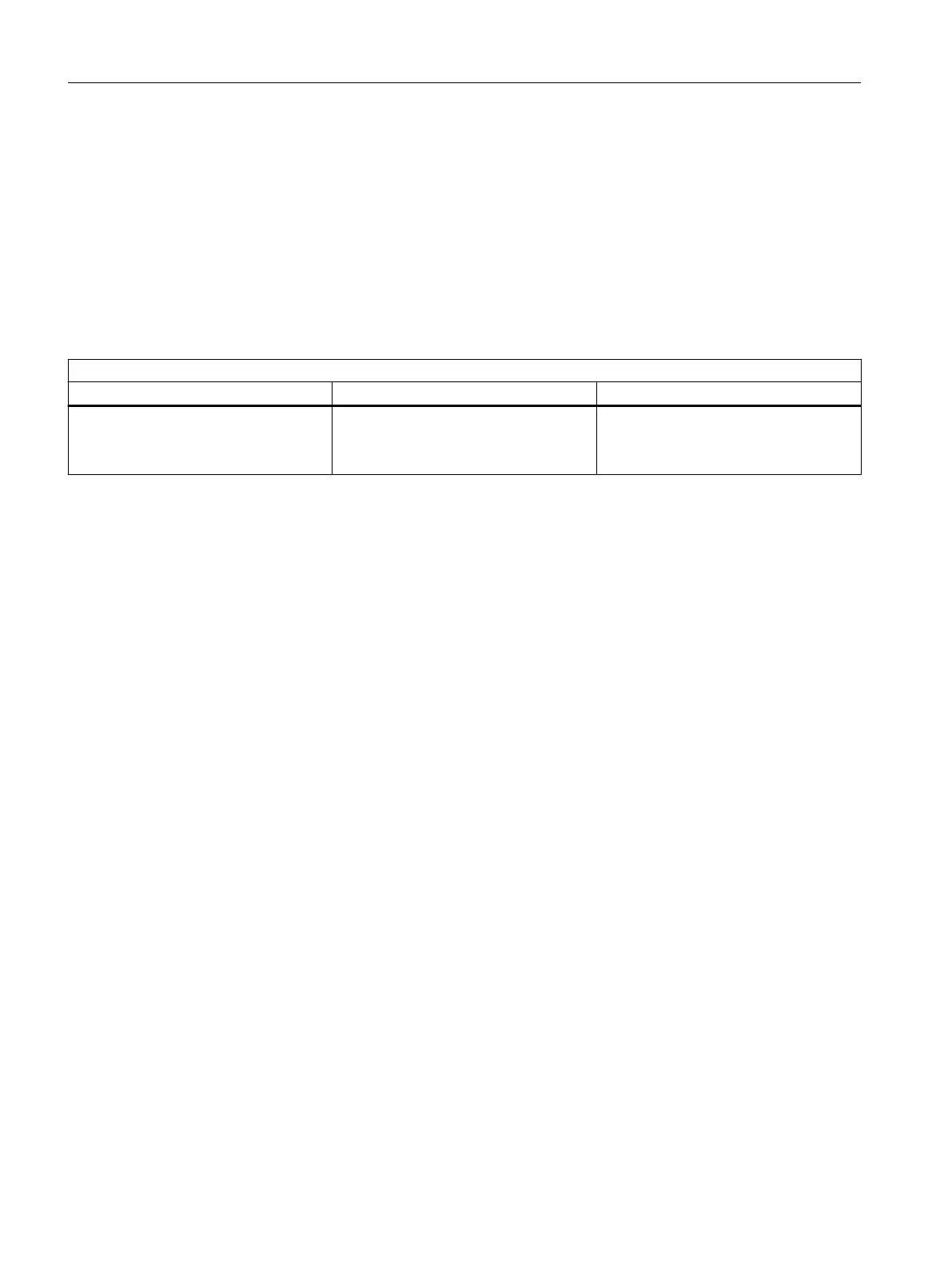

Table 5-1 Number of screws per motor type

Number of screws

4 8 12

1FN3050-1KD00

1FN3100-1KC50

1FN3150-1KC70

1FN3050-2KC40

1FN3100-2KC50

1FN3150-2KC70

-

1FN3100-3KC50

1FN3150-3KC70

• Only use new screws that have not been used before.

• Ensure that the correct types of mounting screws are used to fasten the secondary sections:

– Cylinder head screws with standard head for 1FN3050 to 1FN3150 according to

DIN EN ISO 4762 (hexagon socket-head screw) or DIN EN ISO 14579 (hexalobular screw)

• Ensure that the mounting surfaces are free of oil and grease and are clean and unpainted.

• Comply with the optimal surface roughness depth Rz of the screwing surface. Rz is between

10and 40μm.

• Minimize the number of joints. This keeps the settling eect for the material and the screws

low.

• Carefully maintain the specications for the thread depths and screw-in depths in the primary

section.

• The tightening torque is 7.6Nm.

Tighten the xing screws using torque control. If you cannot tighten the xing screws using

torque control, at least use a calibrated torque wrench with a short wrench insert.

You can increase the load capability of the screwed connection when using a tightening

procedure with controlled angle of rotation or yield limits.

• Tighten the screws gradually, with no jerky movements.

• To secure the screws, select a long clamping length l

k

/d>5.

Alternatively, use a medium strength threadlocker to prevent screws becoming loose, e.g.

Loctite 243.

• Minimize the amount that the screws settle. To do this, retighten all screws.

Installation

5.2Specications for mounting linear motors

Naturally-Cooled 1FN3 Linear Motors

60 Operating Instructions, 06/2023, A5E52220465B AB

Loading...

Loading...