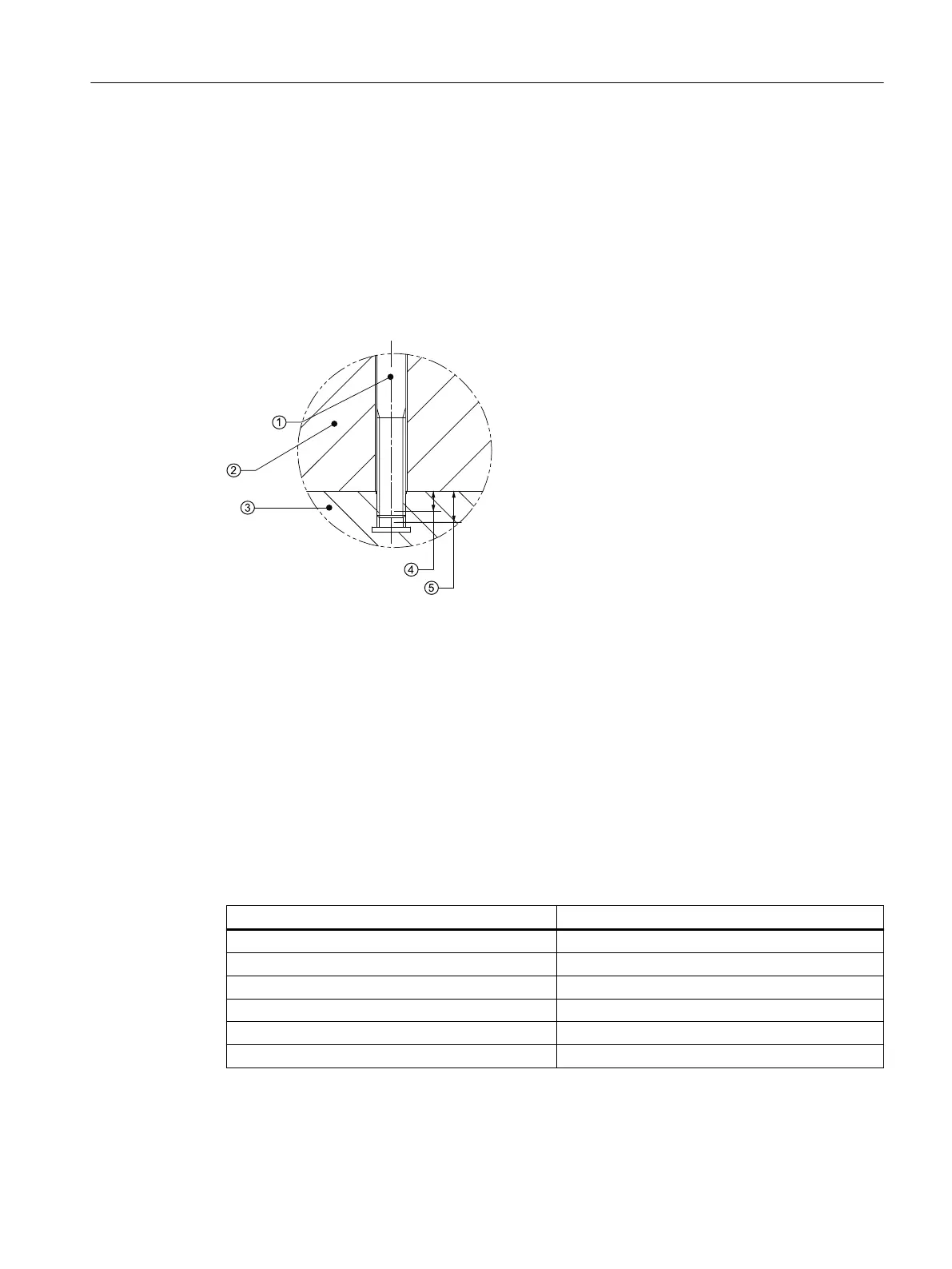

Thread depth and screw-in depths in the primary section

The following drawing schematically illustrates the minimum permissible and maximum screw-

in depth of the xing screws in the screwed-in state. For selecting the screw length, a good

range is thus made available to the machine manufacturer.

The selection of the length of the mounting screws while taking all of the design tolerances

into consideration is the responsibility of the machine manufacturer.

The machine manufacturer must ensure that the minimum screw-in depth is reached and the

maximum screw-in depth is not exceeded.

① Mounting screw ④ Minimum screw-in depth: 8

-2.0

mm

② Slide ⑤ Maximum screw-in depth: 8

+0.0

mm

③ Primary section

Figure5-1 Schematic diagram for the screw-in depths in the primary section

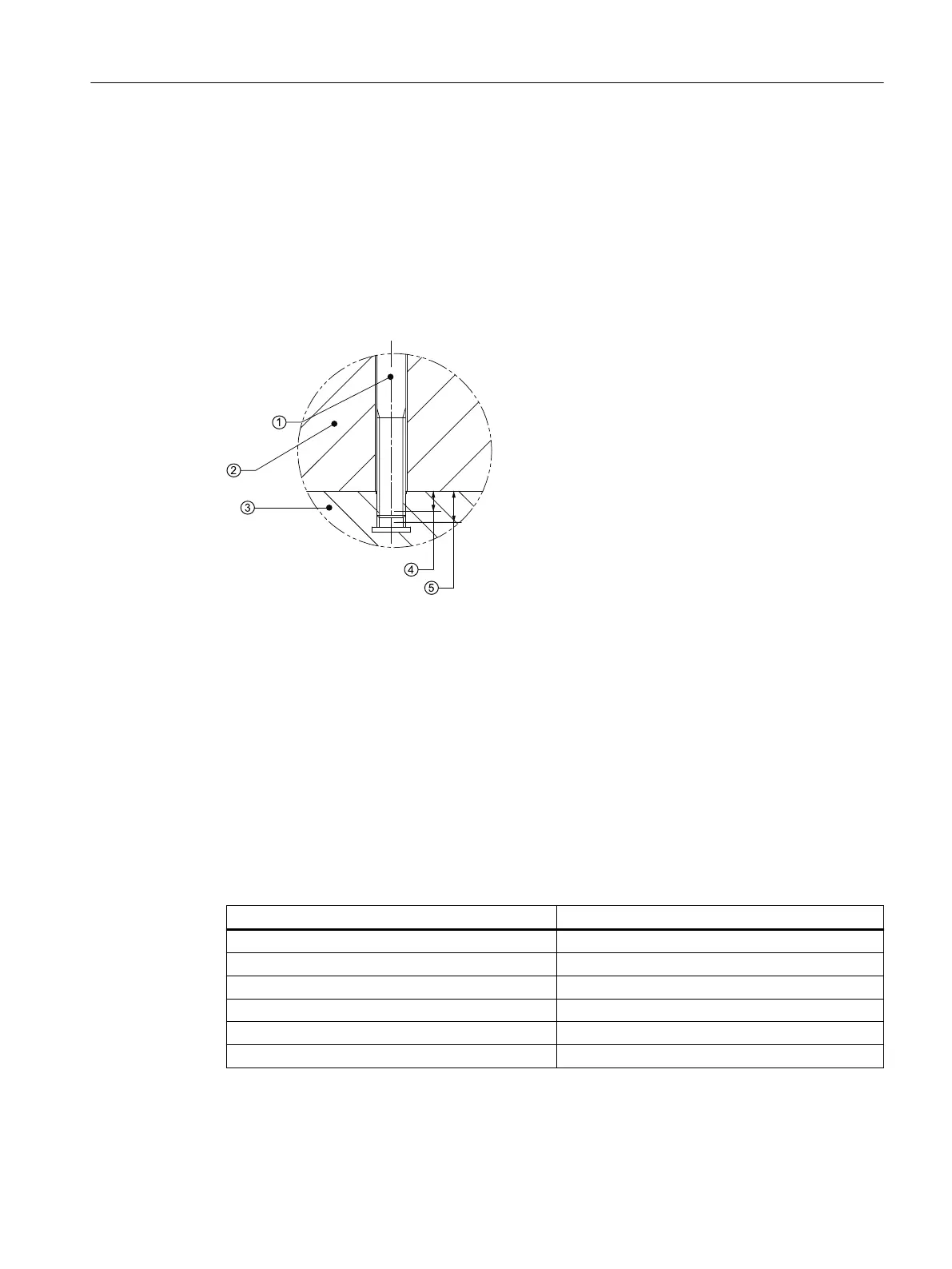

Screw-in depthsfor the secondary section installation

Minimum permissible screw-in depth

The minimum permissible screw-in depths for the most commonly used materials for a

machine bed are listed below. For dierent materials, you must determine the screw-in depth

according to VDI Directive 2230.

Table 5-2 Minimum permissible screw-in depths

Material Screw-in depth

ENGJL‑250 1.4•d

ENGJL‑300 1.3•d

ENGJS‑600‑3 0.7•d

G‑ALZN10Si8Mg 2.8•d

St37 1.8•d

St50 1.3•d

Maximum screw-in depth

The maximum screw-in depth is at the discretion of the machine manufacturer.

Installation

5.2Specications for mounting linear motors

Naturally-Cooled 1FN3 Linear Motors

Operating Instructions, 06/2023, A5E52220465B AB 61

Loading...

Loading...