• Use the mounting screws to force-t the secondary sections to the machine bed.

Note

Hole in the machine bed

The shaft of the bolts, which are used to attach the secondary section to the machine base

may not reach the thread.

• If necessary, you must lower the relevant hole in the machine bed.

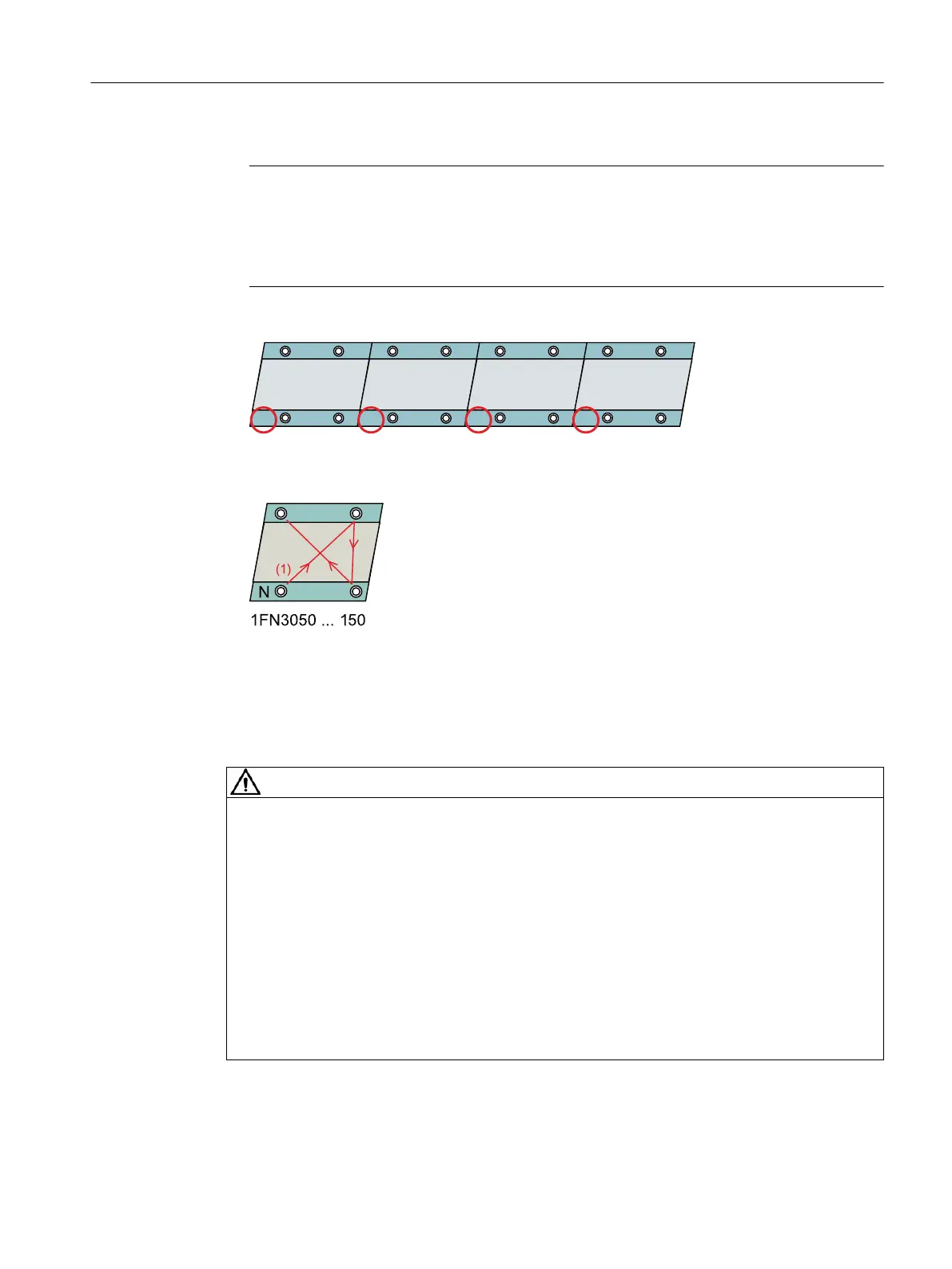

The letter "N" is to be found on each secondary section. Ensure that the letter "N" on each of

the secondary sections is pointing in the same direction, as shown in the following gure.

Figure5-7 Position of the "N" mark on secondary sections of the 1FN3 product family

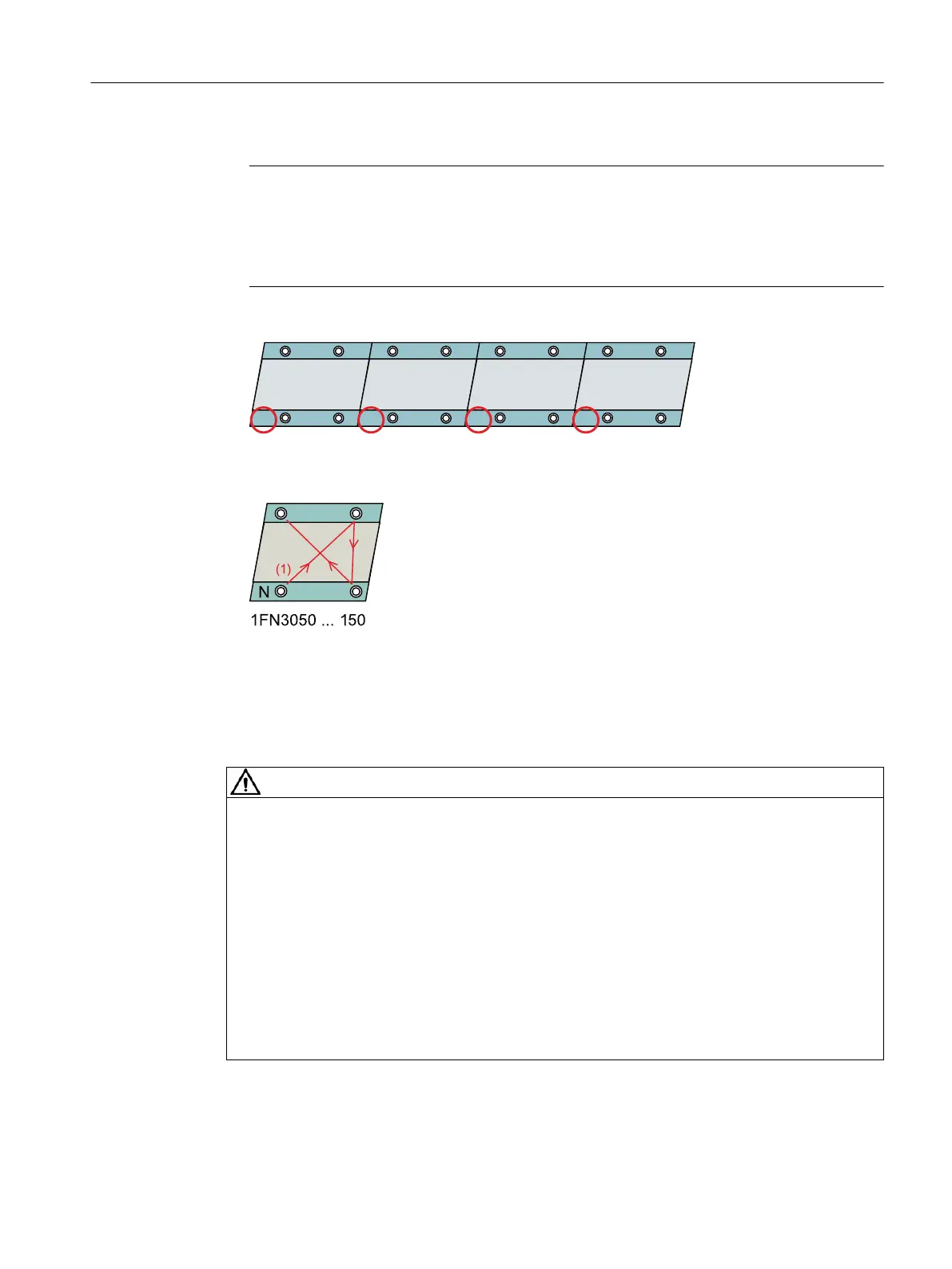

Screw on the secondary sections in the specied sequence as shown in the following gure.

Figure5-8 Screwed joint sequence of 1FN3 secondary sections

❒

5.3.6.2 Installing the secondary section cover

WARNING

Risk of cutting injuries when handling secondary section covers

Secondary section covers have sharp edges. When delivered, the rolled up cover bands for

secondary sections are secured using straps that are under spring tension.

If you cut through these straps, then the rolled up cover bands can suddenly unroll. You can

incur cutting injuries at your hands and eyes if you do not wear safety gloves and adequate eye

protection.

• Always wear safety gloves when handling secondary section covers

• Always wear suitable eye protection when unpacking cover bands

• Work in pairs where necessary

• Firmly hold the rolled up cover bands when cutting through the straps

• Allow the cover bands to slowly unroll

Installation

5.3Procedure when installing the motor

Naturally-Cooled 1FN3 Linear Motors

Operating Instructions, 06/2023, A5E52220465B AB 71

Loading...

Loading...