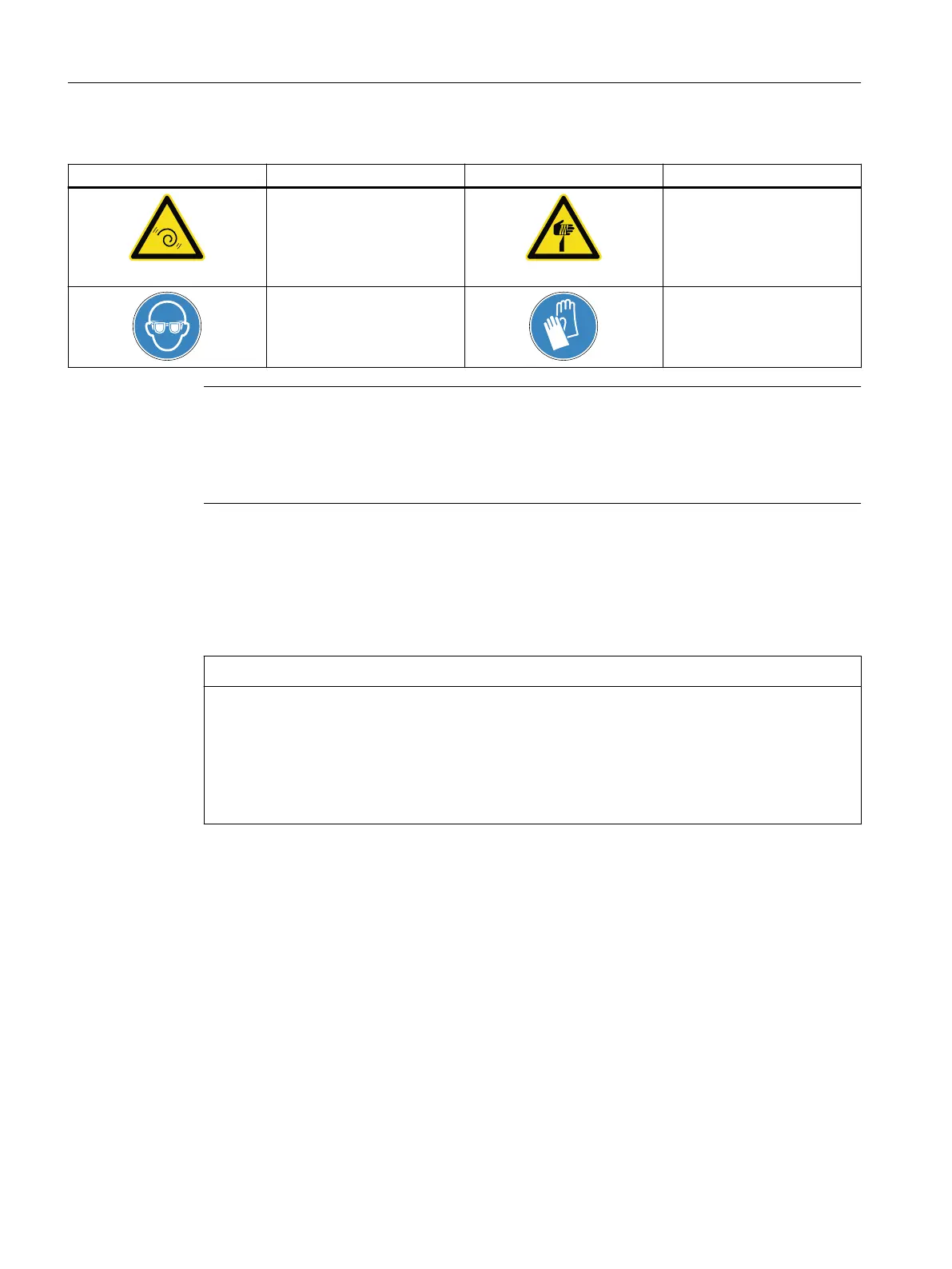

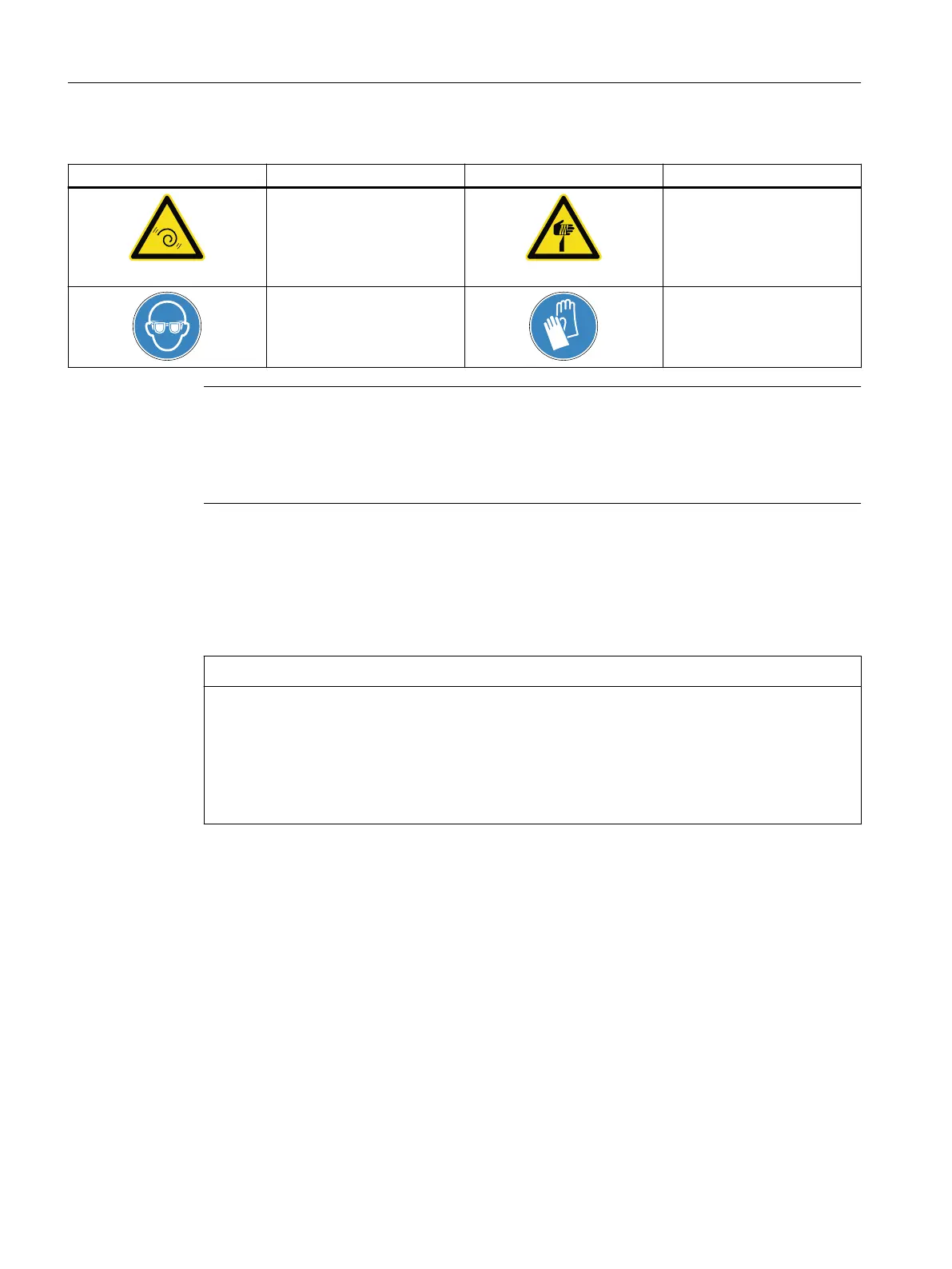

Table 5-4 Safety pictograms on the packaging for secondary section covers as continuous cover bands

Pictogram Meaning Pictogram Meaning

Warning against the secon‐

dary section cover band sud‐

denly unrolling

(Non-standardized warning

sign)

Warning against pointed/

sharp object

(ISO7010-W022)

Use eye protection

(ISO7010-M004)

Use protective gloves

(ISO7010-M009)

Note

Lower motor force for a larger air gap

If you use a secondary section cover, then the air gap between the primary section and

secondary section must be increased by 0.4mm. The motor force is then reduced by approx.

10%.

The secondary section cover protects the secondary section track. The installation method

depends on the type of cover. The following 2 variants are available:

• Continuous cover band

• Segmented cover

NOTICE

Loss of functionality and motor wear due to contamination in the motor compartment

Contamination in the motor compartment can cause the motor to stop functioning or cause

wear and tear. The use of scrapers to keep the air gap free is not sucient and therefore not

recommended.

• Use suitable measures to protect the motor compartment from contamination

independently of the use of a cover band.

Covering long secondary section tracks with cover bands is more complicated than with

segments.

Requirements

On the machine side, always carefully ensure that the linear motor is protected against all types

of dirt and pollution. The cover plates of the secondary sections and the stainless steel cover of

the primary section towards the air gap serve as protection against dirt and pollution, which

cannot be prevented using machine-side shielding.

The cover plates for the secondary sections primarily protect the secondary section surface

against being mechanically damaged, for instance, resulting from deposits of dust, sand,

metal chips, machine parts etc.

Installation

5.3Procedure when installing the motor

Naturally-Cooled 1FN3 Linear Motors

72 Operating Instructions, 06/2023, A5E52220465B AB

Loading...

Loading...