Local measuring input Global measuring input

Measuring on virtual axes no yes

Measuring on axes attached to a

different drive unit

no yes

1)

Measurement jobs must be issued individually for each measurement. Several interpolation cycle clocks lie between two

measurements.

2)

The measuring is activated just once and runs cyclically until deactivated.

SIMOTION Utilities & Applications includes, for example, a tool with the following functions:

●

Estimate of the time between initiating a measurement job to the time at which the

measuring input job in the drive acts

● Estimate of the minimum time between 2 measurement jobs.

SIMOTION Utilities & Applications is part of the scope of delivery of SIMOTION SCOUT.

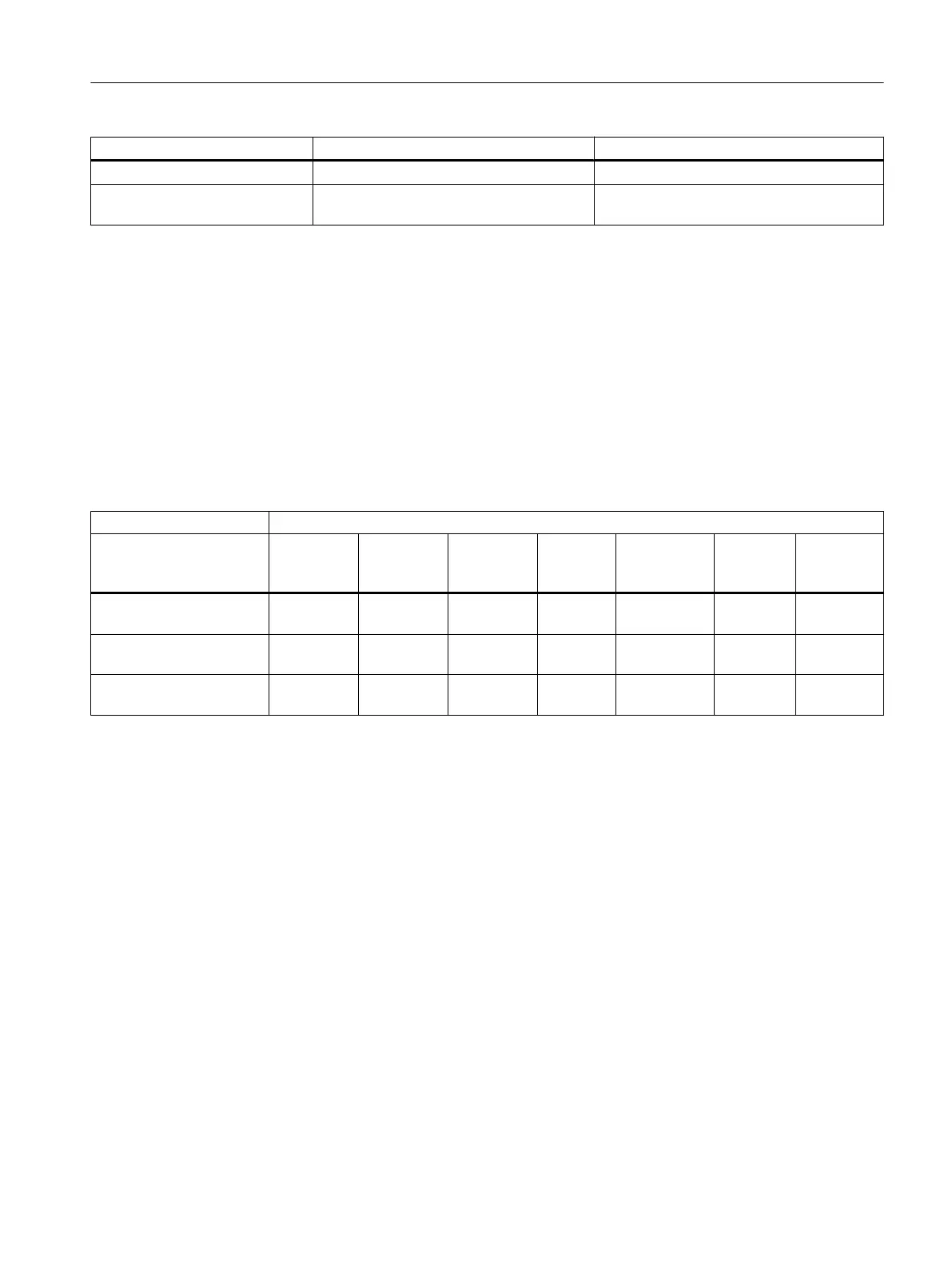

Table A-2 Measuring inputs - Overview of quantity structures and functionality

Maximum available quantity structure

Functionality/device D410,

CU310,

CX32

D4x5,

CU320

CX32‑2 D410-2,

CU310-2

D4x5‑2

‑ X122/X132

‑ X142

TM15 TM17 High

Feature

Maximum number of

measuring input inputs

3 6 4 8 - 8

- 8

24 16

Can be configured as a lo‐

cal measuring input

x x x x - 8

- 0

- -

Can be configured as a

global measuring input

x x x x - 8

- 8

x x

Configuring drive-related I/Os (without symbolic assignment)

A.2 Local and global measuring inputs

SIMOTION D410-2

Commissioning and Hardware Installation Manual, 01/2015 319

Loading...

Loading...