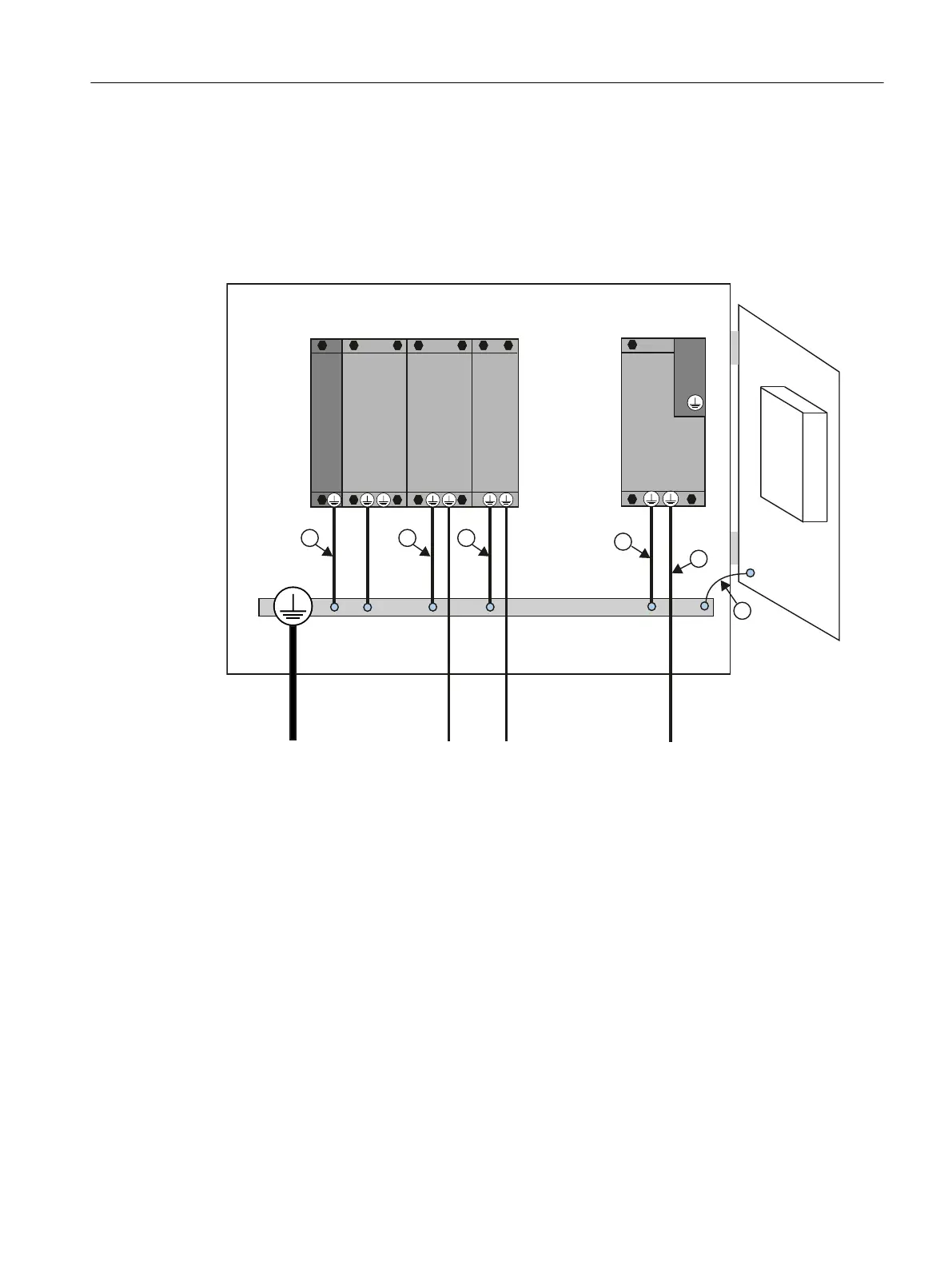

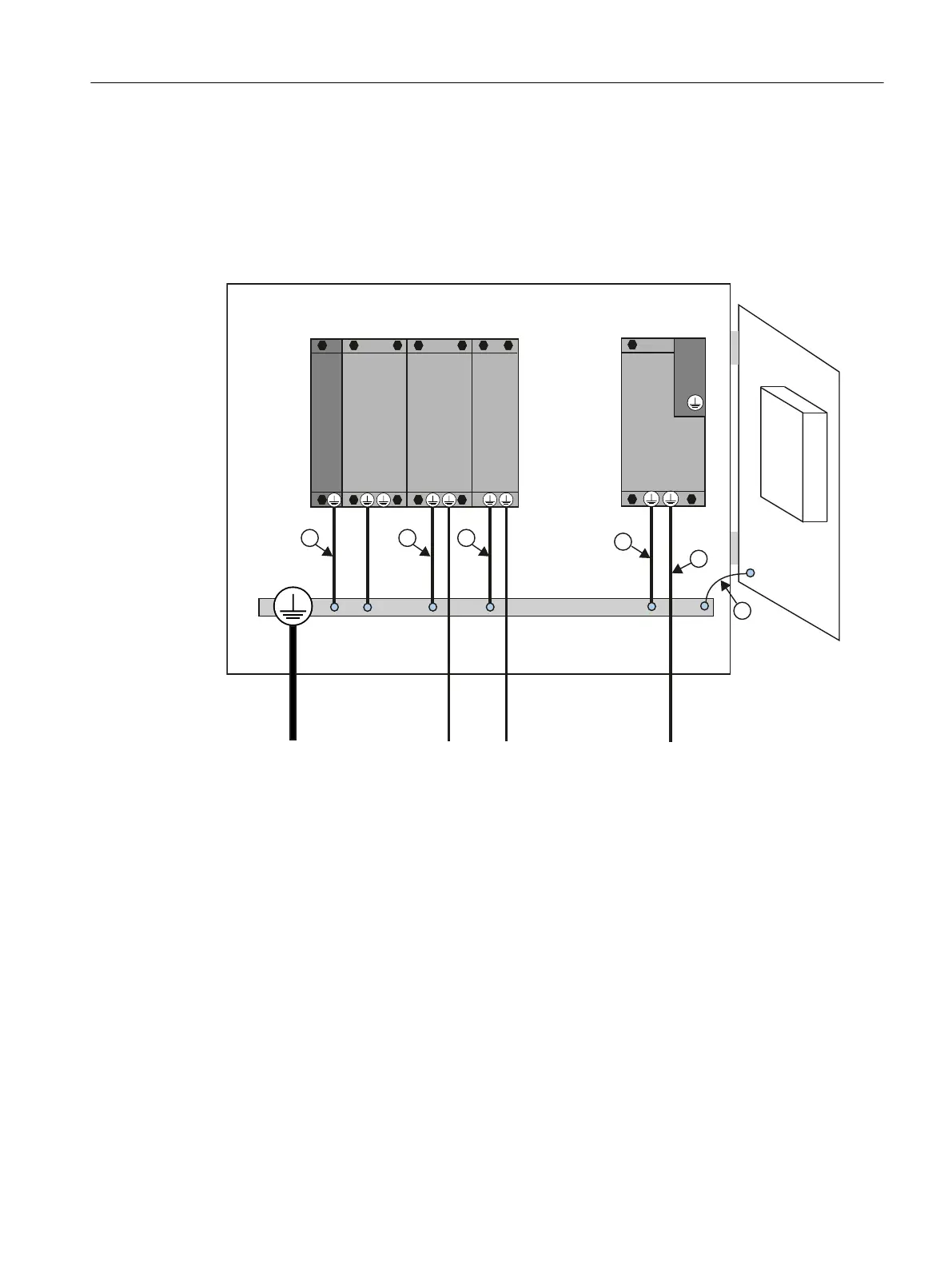

Equipotential bonding

A

mounting plate serves simultaneously as an equipotential bonding surface. This means that

no additional equipotential bonding is required within the drive line-up. If a common bright

mounting plate is not available, then equally good equipotential bonding ⑨ must be

established using cable cross-sections as listed in the table above or, as a minimum, with the

same conductivity.

'RRU

&8/0000030

&8

+0,

6

%ORFNVL]H

6

%RRNVL]H

Figure 4-5 Protective conductor connection, cabinet without equipotential bonding surface

Communication links

Within the same control cabinet, no equipotential bonding conductor is required for fieldbus

components if they installed as described above.

You have to ensure equipotential bonding for communication connections between remote

components

in a system (e.g. devices in different control cabinets) as well as between buildings

or building sections.

If, for example, data cables (PROFIBUS, PROFINET, Ethernet or DRIVE‑CLiQ) are routed

through several control cabinets, equipotential bonding must be established with an

equipotential bonding conductor. Install the equipotential bonding conductor together with the

data cable.

The following minimum cross-sections are required according to IEC 60364-5-54:

● For copper, at least 6 mm²

● For aluminum, at least 16 mm²

● For steel, at least 50 mm²

Connecting

4.3 Protective conductor connection and potential equalization

SIMOTION D410-2

Commissioning and Hardware Installation Manual, 01/2015 53

Loading...

Loading...