Cycles

9.10 Shoulder plunge-cutting – CYCLE412

Cylindrical grinding

182 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

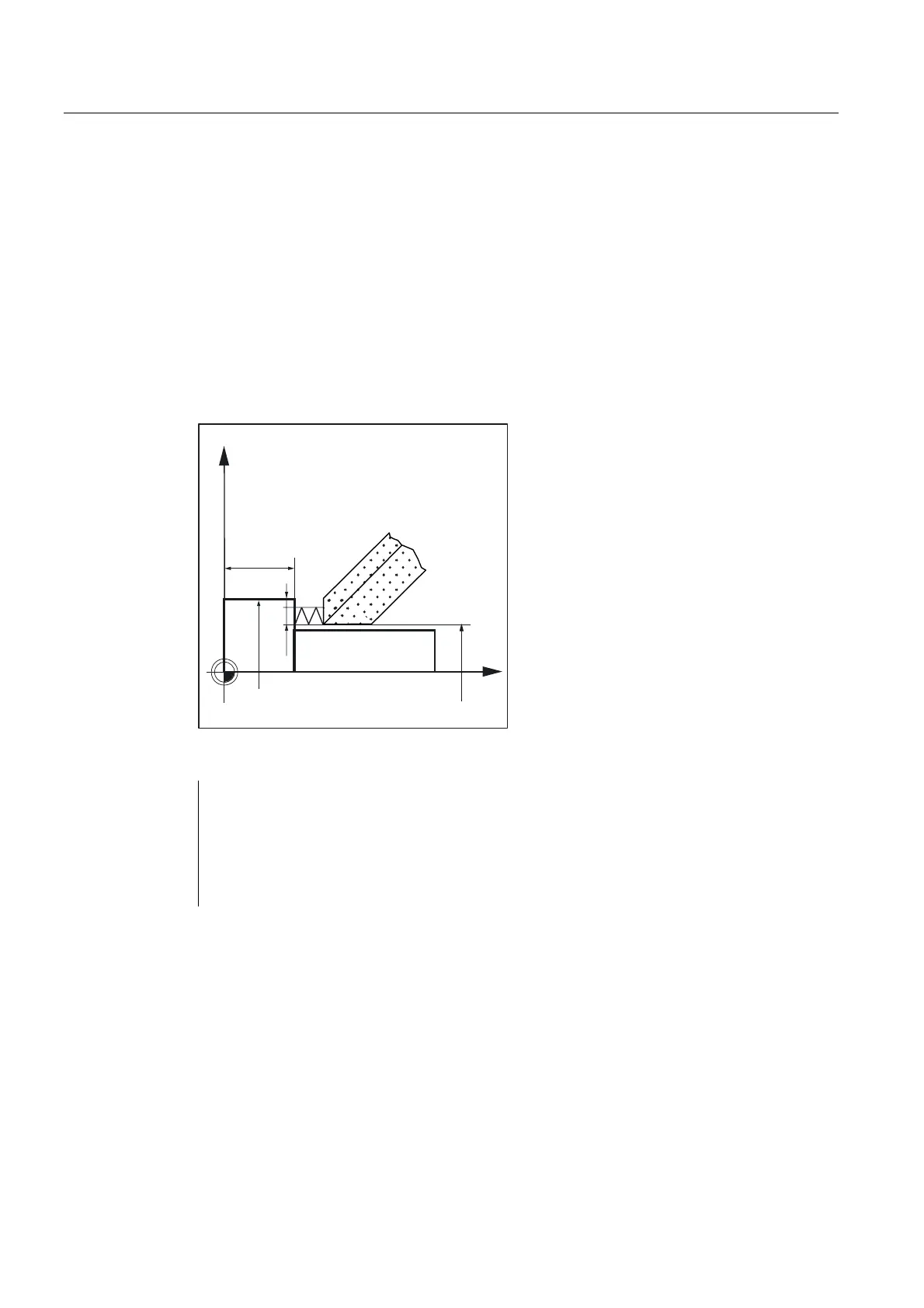

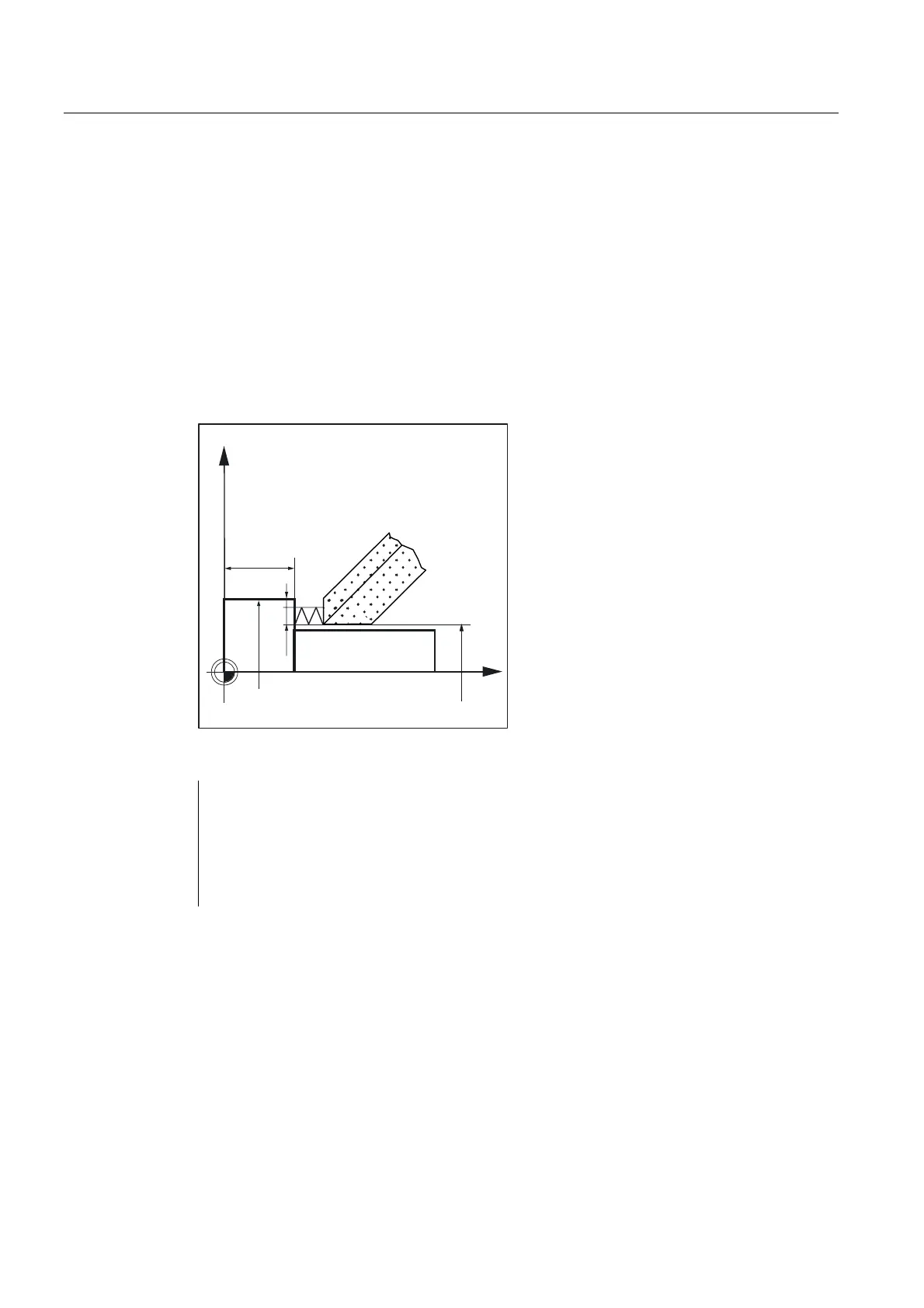

Example for shoulder plunge-cutting

Complete machining of a shoulder to a width of 50 mm with reciprocation using an acoustic

emission sensor.

Additional specified values

Z_SCH=50 mm Shoulder dimension in Z

A_SR=0.2 mm Roughing allowance

A_SL=0.1 mm Finishing allowance

TIME=5 s Sparking-out time

;

=

N10 T1 D1 M7 ; Determine technology values, coolant ON

N20 S1=2000 M1=3 ; Turn on workpiece speed

N30 S2=1100 M24 ; Turn on wheel speed

N40 CYCLE412(1, 50, 192, 3, 5, 0.2, 0.1,

45, 30, 5, 1, 600, 5, 500, 20)

; Cycle call

N50 M30 ; End of program

Sequence of operations

The machining start position is first approached in X, then in Z, corresponding to the initial

position of the grinding wheel in Z, if the current X value is less than the X allowance.

The Z starting position is calculated as the shoulder dimension in Z + roughing allowance +

air allowance.

The surface can be sparked using an acoustic emission sensor. Optionally, the reciprocating

motion is activated in X, and the subsequent roughing operation is performed by plunge-

cutting up to finishing allowance. After finishing and expiry of the sparking-out time, the

reciprocation motion stops, and the wheel retracts to the starting position.

Loading...

Loading...