Cycles

9.14 Dressing and profiling – CYCLE416

Cylindrical grinding

200 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

9.14 Dressing and profiling – CYCLE416

Programming

CYCLE416(X_AB, Z_AB_L, Z_AB_R, FFW, F_DL_AB, F_BL_AB, F_DR_AB, F_BR_AB,

F_Z_AB, N_ABR, USCH, N_AWST)

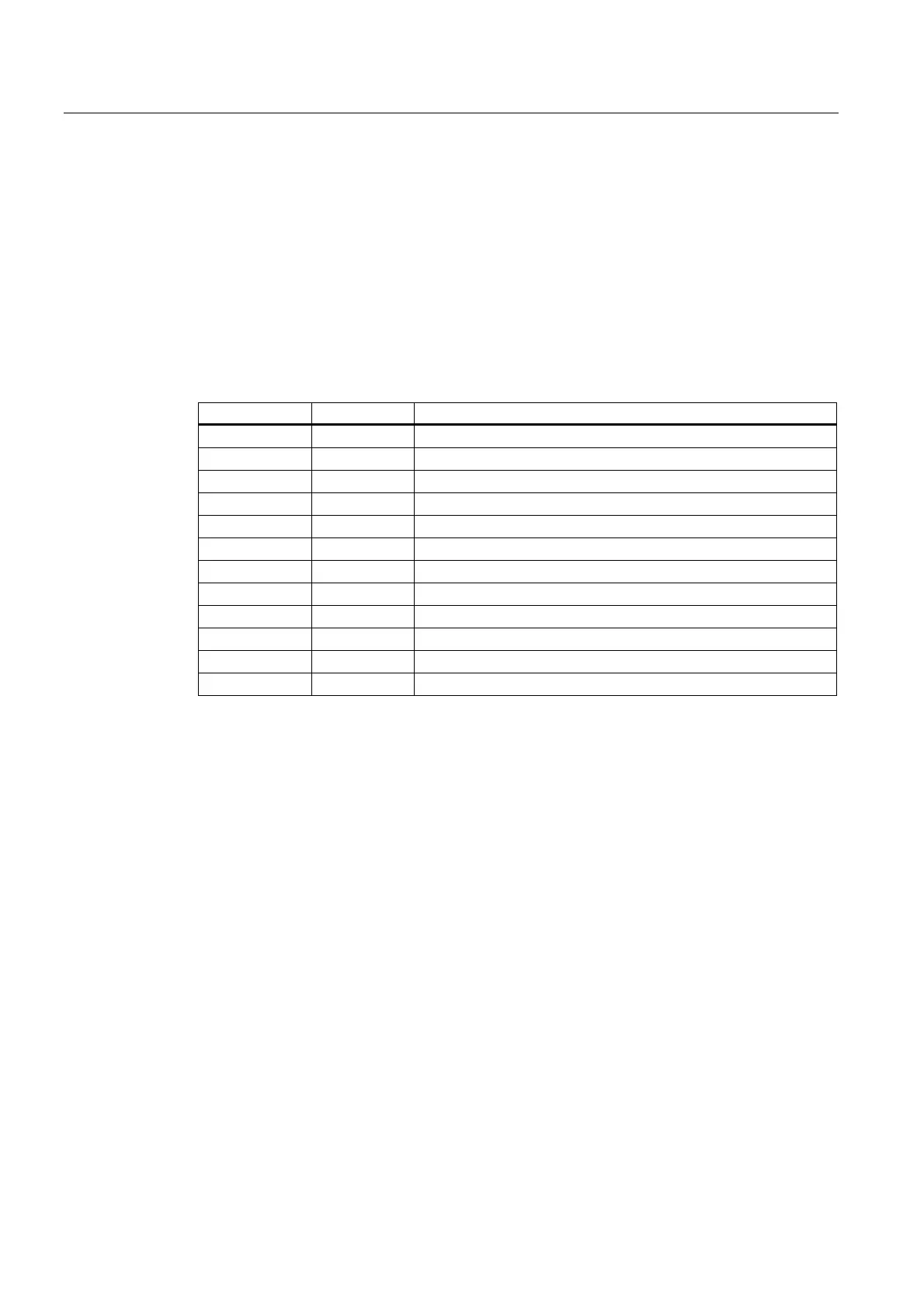

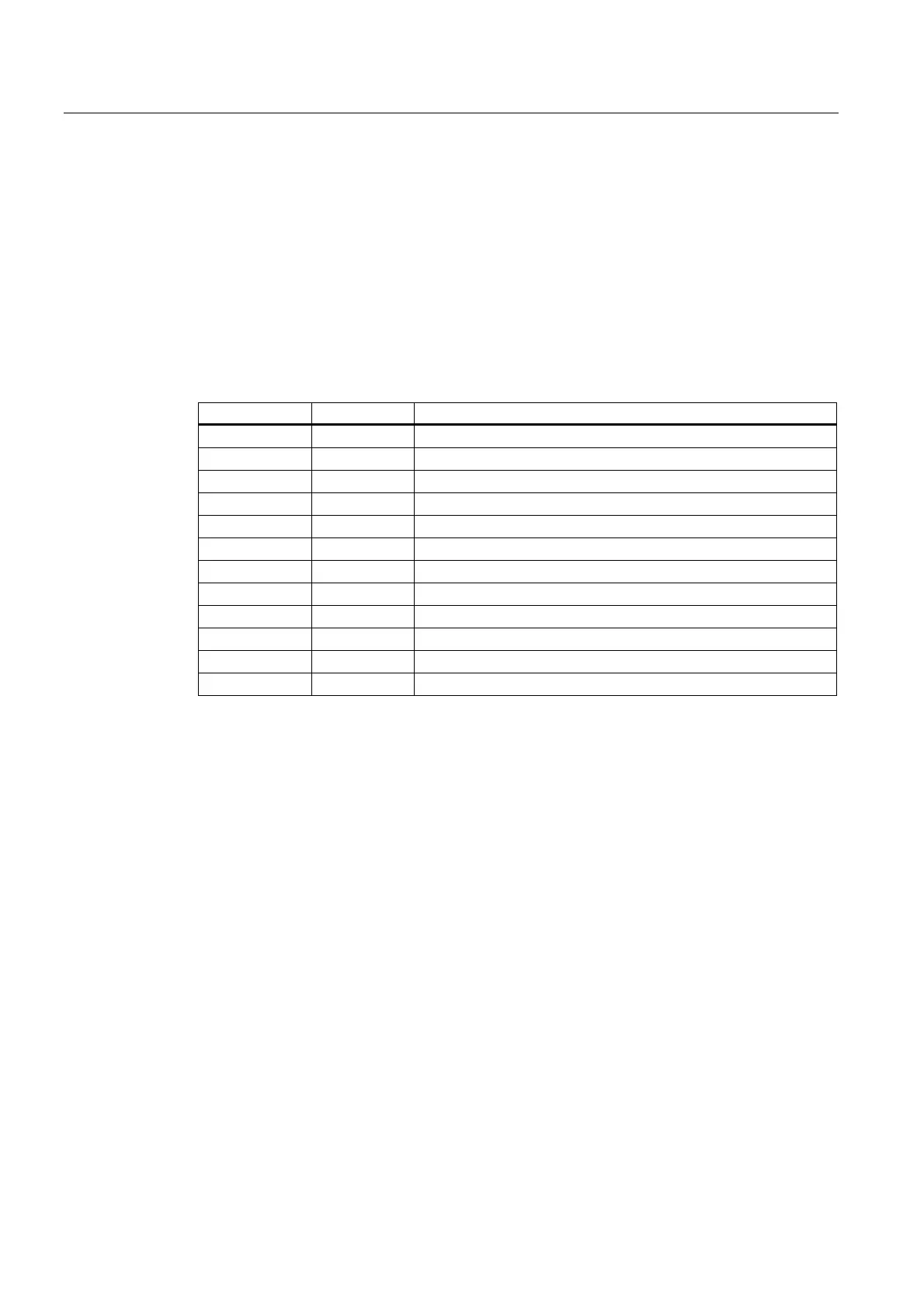

Parameter

Table 9- 11 Parameters of CYCLE416

Parameter Data type Meaning

X_AB REAL Dressing amount in X (incr.)

Z_AB_L REAL Dressing amount in Z, left (incr.)

Z_AB_R REAL Dressing amount in Z, right (incr.)

FFW REAL Retraction travel (incr.)

F_DL_AB REAL Dressing feedrate in X, left

F_BL_AB REAL Dressing feedrate in the path, left

F_DR_AB REAL Dressing feedrate in X, right

F_BR_AB REAL Dressing feedrate in the path, right

F_Z_AB REAL Dressing feedrate in Z

N_ABR INT Number of dressing strokes

USCH REAL Wheel peripheral speed

N_AWST INT Number of workpieces between two dressers

Function

The "Dressing and profiling" cycle calculates the starting positons and internally calls

CYCLE432.

This cycle incorporates the geometry of the two wheel types 'straight' and 'inclined', as well

as 'with and without corner radius', 'chamfer', 'relief cut' and 'shoulder'. The parameters are

read in the program from D1-D6 (refer to "Tools and Tool Radius Compensation")

When dressing, the dressed amount is taken into account in the wear parameters of the

current tool offset.

Loading...

Loading...