Cycles

9.12 Radius grinding – CYCLE414

Cylindrical grinding

190 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

9.12 Radius grinding – CYCLE414

Programming

CYCLE414(N_SITZ, Z_SCH, X_ST, RAD, LAGE, A_LU, A_SR, F_SR, KS, F_KS, UWERK)

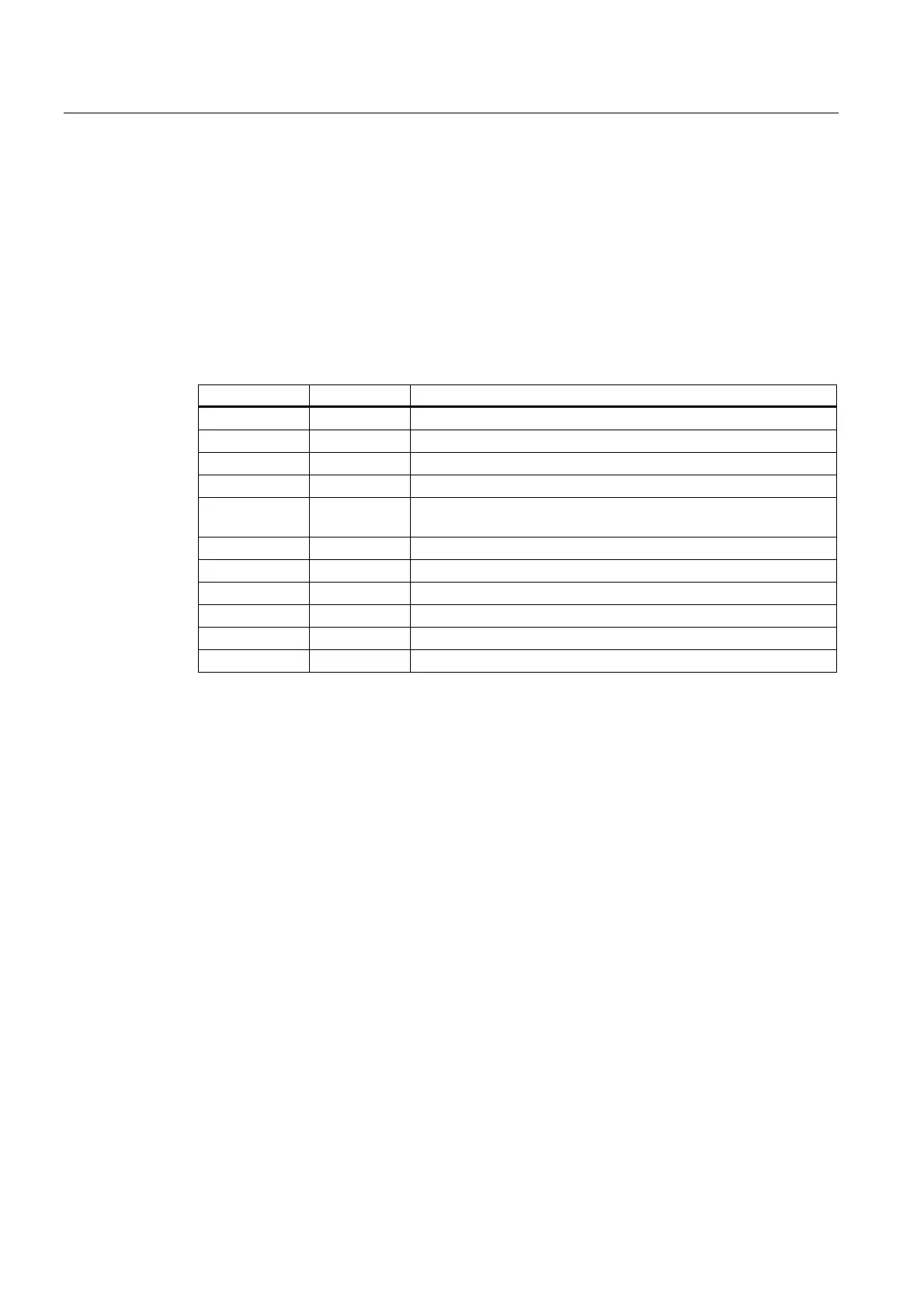

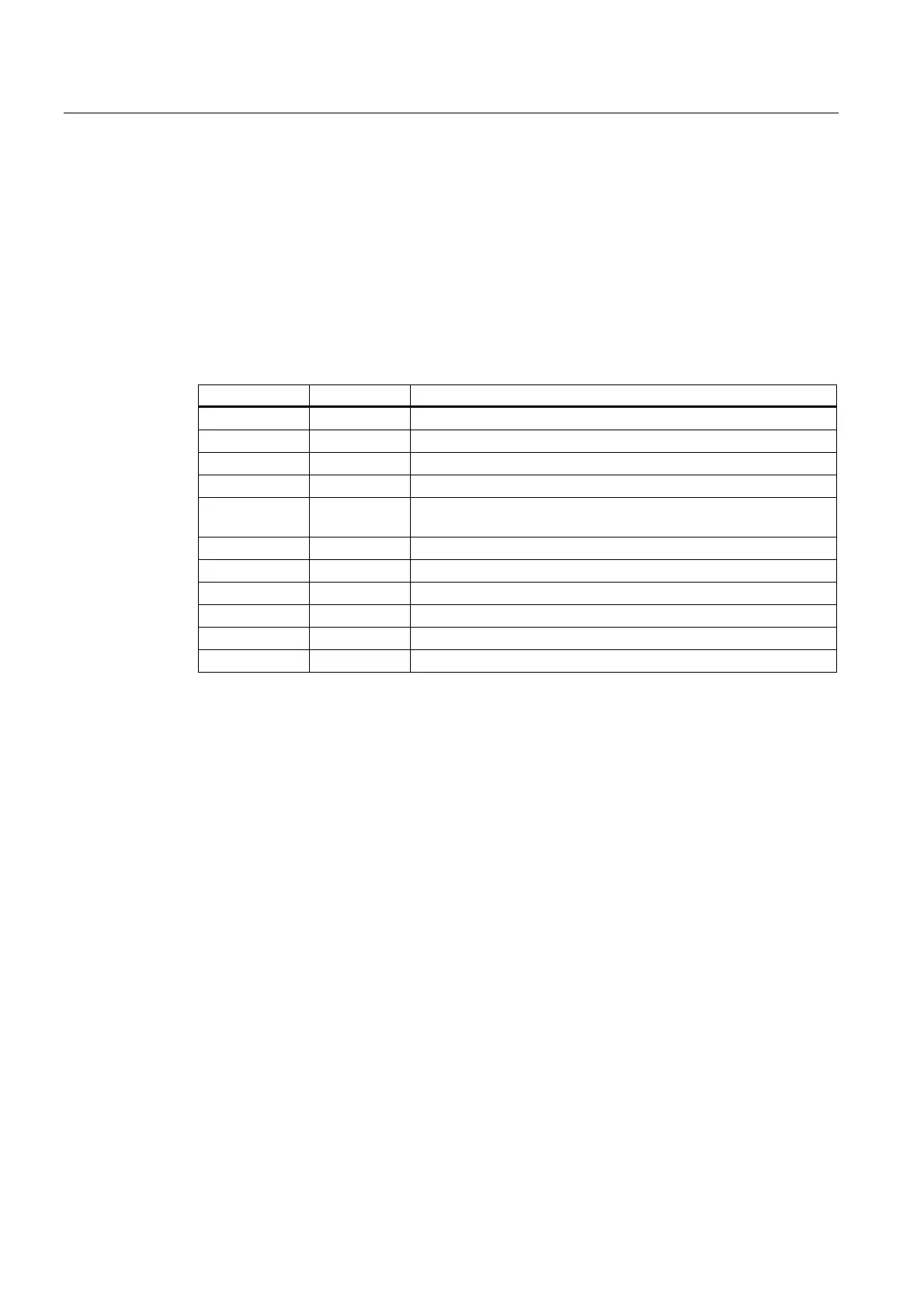

Parameter

Table 9- 9 Parameters of CYCLE414

Parameter Data type Meaning

N_SITZ INT Seat number

Z_SCH REAL Shoulder dimension in Z (abs.)

X_ST REAL Starting position in X (abs.)

RAD REAL Workpiece radius

LAGE INT 23 = internal corner

31 = external corner

A_LU REAL Air allowance (incr.)

A_SR REAL Roughing allowance (incr.)

F_SR REAL Feedrate for roughing

KS INT Acoustic emission sensor Y=1 / N=0

F_KS REAL Feedrate for air grinding [mm/min]

UWERK REAL Workpiece peripheral speed [m/min]

Function

The radius grinding cycle is called whenever an internal or external radius is to be ground

with continuous-path control. In this case, the workpiece radius must always be greater than

the wheel radius. Radius grinding only involves roughing.

A acoustic emission sensor can be used to bridge the distance between the starting point

and the actual workpiece surface within an optimum time by sparking.

Loading...

Loading...