Programming

10.6 Tool and tool offset

Cylindrical grinding

298 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

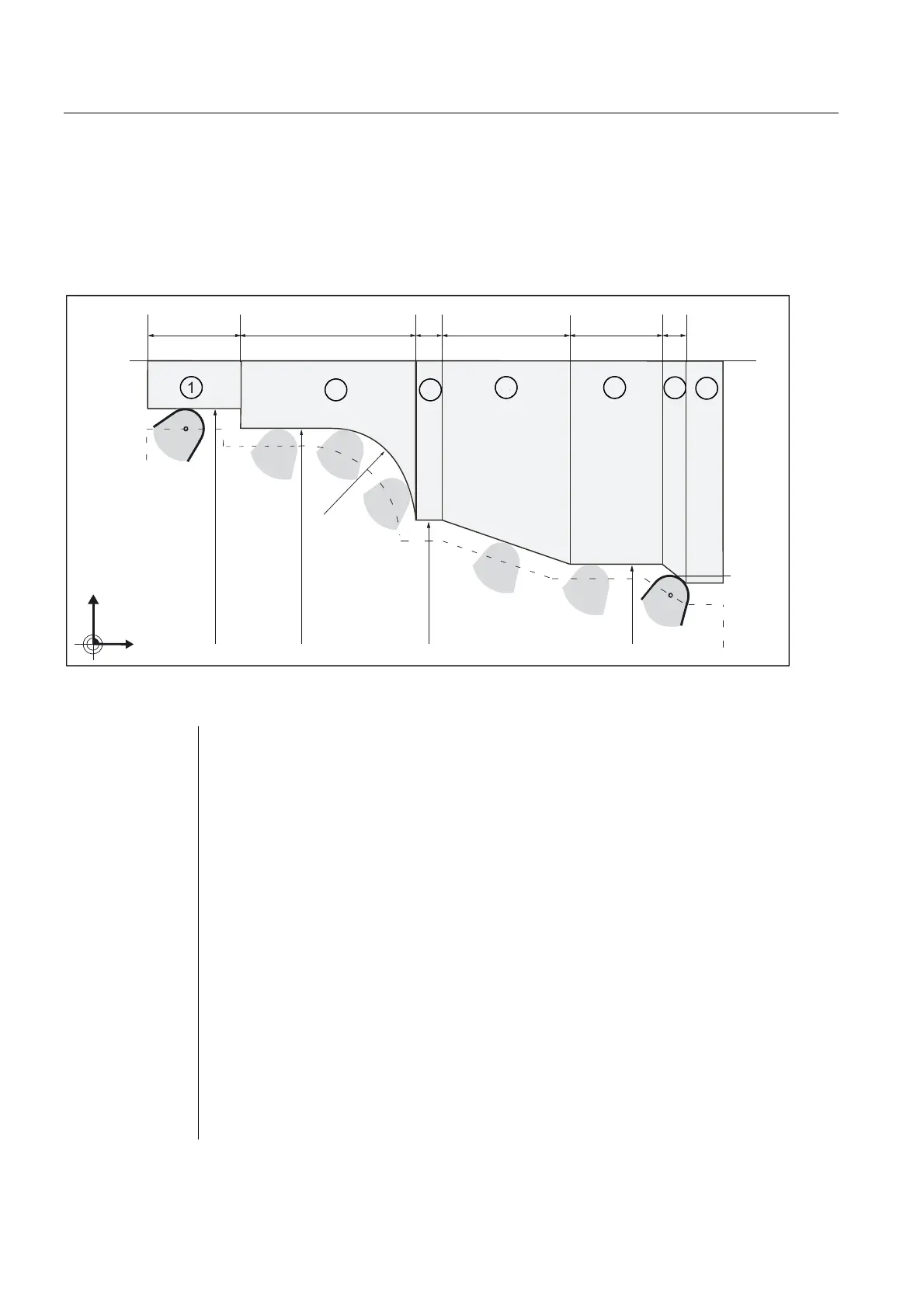

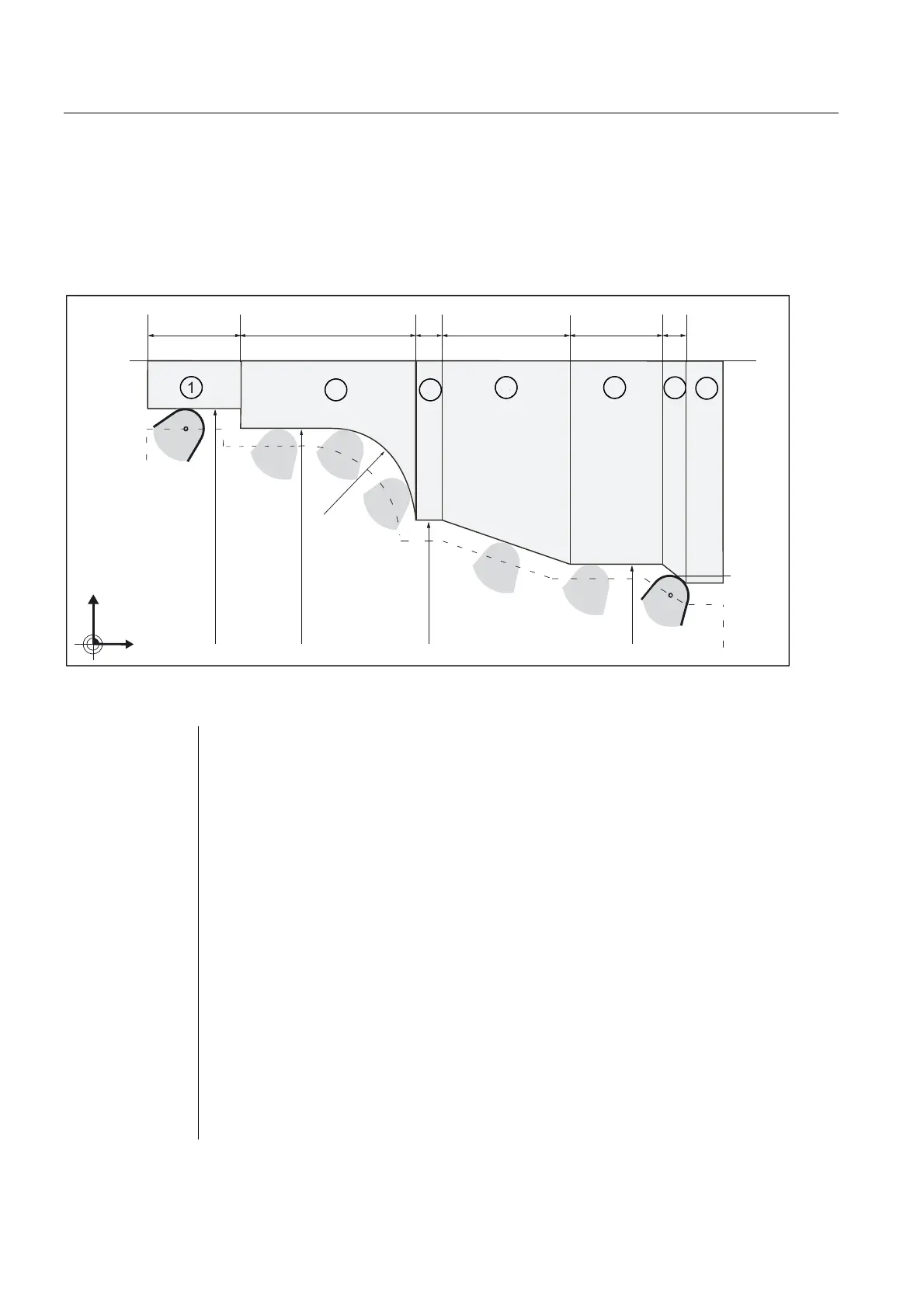

10.6.8 Example of tool radius compensation

The wheel should have the contour shown in the figure. Dressing takes place from left to

right using MIRROR and G41

Caution: The workpiece zero (XWP) in wheel data must be -110 to be able to program the

contour in workpiece coordinates.

S

S

S

S

;

=

r

5

5

5

5

5

Figure 10-34 Example for contour dressing

N1 ; Contour cut

N10 DIAMON F... S... M... ; Radius dimension, technological values

N15 G500 ; Work offset "OFF"

N20 MIRROR X0 Z0 ; Begin compensation mode

N30 G90 G0 X-90

N40 Z-10

N50 X110 ; Approach R55

N60 G41 G64 G1 Z20 F500 ; Dressing contour section ①

N70 X100

N80 Z60 RND=20 ; Dressing contour section ①

N90 X60

N100 Z68 ; Dressing contour section ①

N110 X40 Z98 ; Dressing contour section ①

N120 Z118 ; Dressing contour section ①

N130 X30 Z123 ; Dressing contour section ①

N140 Z123 ; Dressing contour section ①

N150 G0 X-90 ;Move clear

N160 MIRROR ; End compensation mode

M17

Loading...

Loading...