Programming

10.1 Fundamental Principles of NC Programming

Cylindrical grinding

236 Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

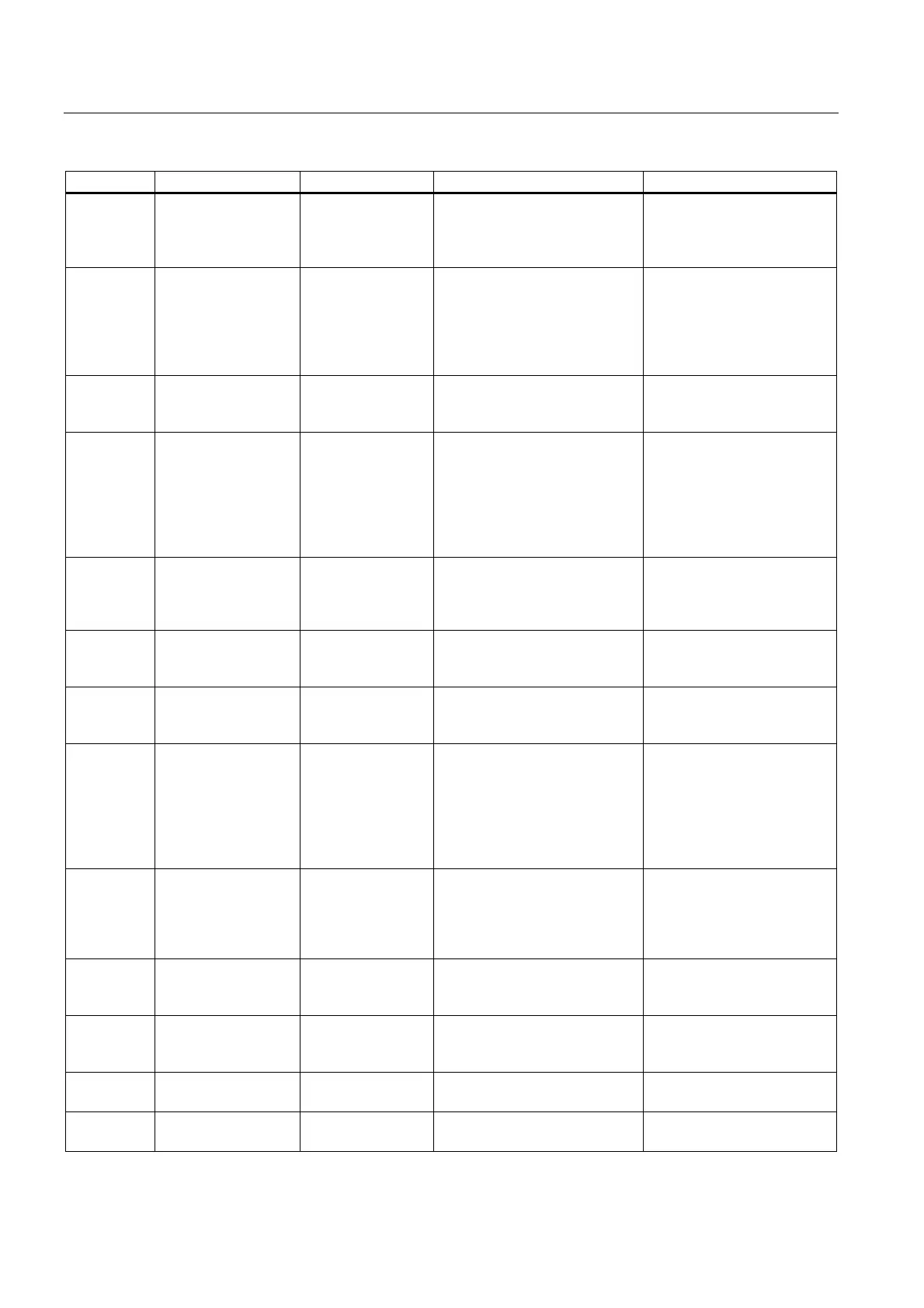

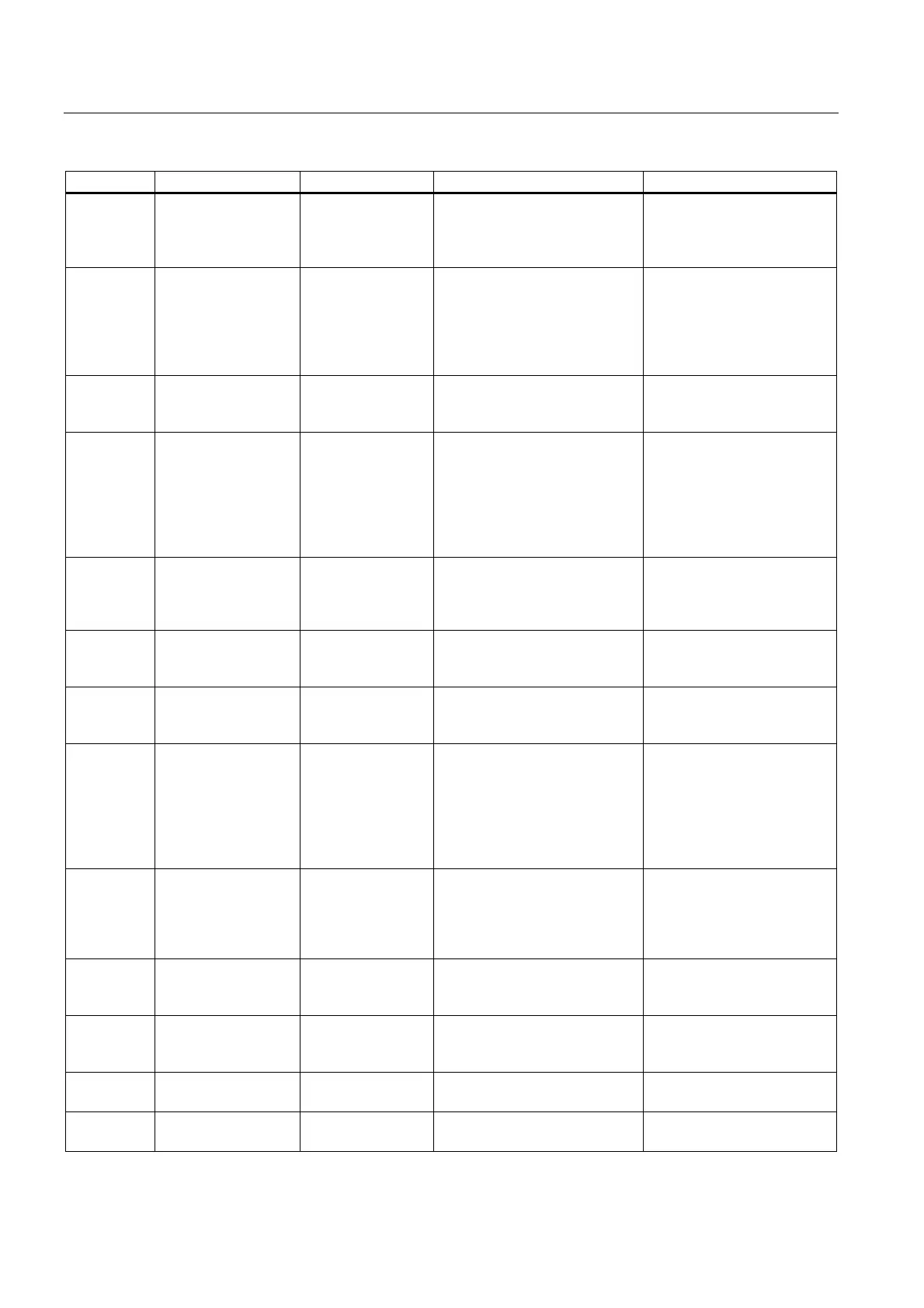

Address Meaning Value assignments Information Programming

RND Rounding 0.010 ... 99

999.999

Inserts a rounding with the

specified radius value

tangentially between two

contour blocks

N10 X... Z.... RND=...

N11 X... Z...

RNDM Modal rounding 0.010 ... 99

999.999

0

- Inserts roundings with the

specified radius value

tangentially at the following

contour corners; special

feedrate possible:FRCM= ...

- Modal rounding OFF

N10 X... Y.... RNDM=.7.3

;modal rounding ON

N11 X... Y...

....

N100 RNDM=.0 ;modal

rounding OFF

RPL Angle of rotation with

ROT, AROT

±0.00001 ...

359.9999

Specification in degrees; angle

for a programmable rotation in

the current plane G17 to G19

see ROT, AROT

SET( , , , )

REP()

Set values for the

variable fields

SET: Various values, from the

specified element up to:

according to the number of

values

REP: the same value, from the

specified element up to the end

of the field

DEF REAL

VAR2[12]=REP(4.5) ; all

elements value 4.5

N10 R10=SET(1.1,2.3,4.4) ;

R10=1.1, R11=2.3, R4=4.4

SETMS(n)

SETMS

Define spindle as

master spindle

n= 1 or n= 2 n: Number of the spindle,

if only SETMS is set, the default

master spindle comes into

effect

N10 SETMS(2) ; separate

block, 2nd spindle = master

SF Thread starting point

when using G33

0.001 ... 359.999 Specified in degrees; the thread

starting point with G33 will be

offset by the specified value

See G33

SPI(n) converts the spindle

number n into the

axis identifier

n =1 or =2,

axis identifier: e.g. "SP1" or "C"

SPOS

SPOS(n)

spindle position 0.0000 ... 359.9999 specified in degrees; the

spindle stops at the specified

position (to achieve this, the

spindle must provide the

appropriate technical

prerequisites: position control)

Spindle number n: 1 or 2

N10 SPOS=....

N10 SPOS=ACP(...)

N10 SPOS=ACN(...)

N10 SPOS=IC(...)

N10 SPOS=DC(...)

STOPFIFO Stops the fast

machining step

Special function;

filling of the buffer memory until

STARTFIFO, "Buffer memory

full" or "End of program" is

detected.

STOPFIFO; separate block,

start of filling

N10 X...

N20 X...

STARTFIFO Start of fast

machining step

Special function;

the buffer memory is filled at the

same time.

N30 X...

STARTFIFO ;separate block,

end of filling

STOPRE Preprocessing stop Special function; the next block

is only decoded if the block

before STOPRE is completed.

STOPRE ; separate block

TRAFOOF Switch off TRAANG - Disables all kinematic

transformations

TRAFOOF ; separate block

TRAANG Inclined axis

transformation

TRAANG(30) ; 30°

Loading...

Loading...