Automatic mode

6.3 Selection and start of a part program

Cylindrical grinding

Programming and Operating Manual, 07/2009, 6FC5398-4CP10-2BA0

85

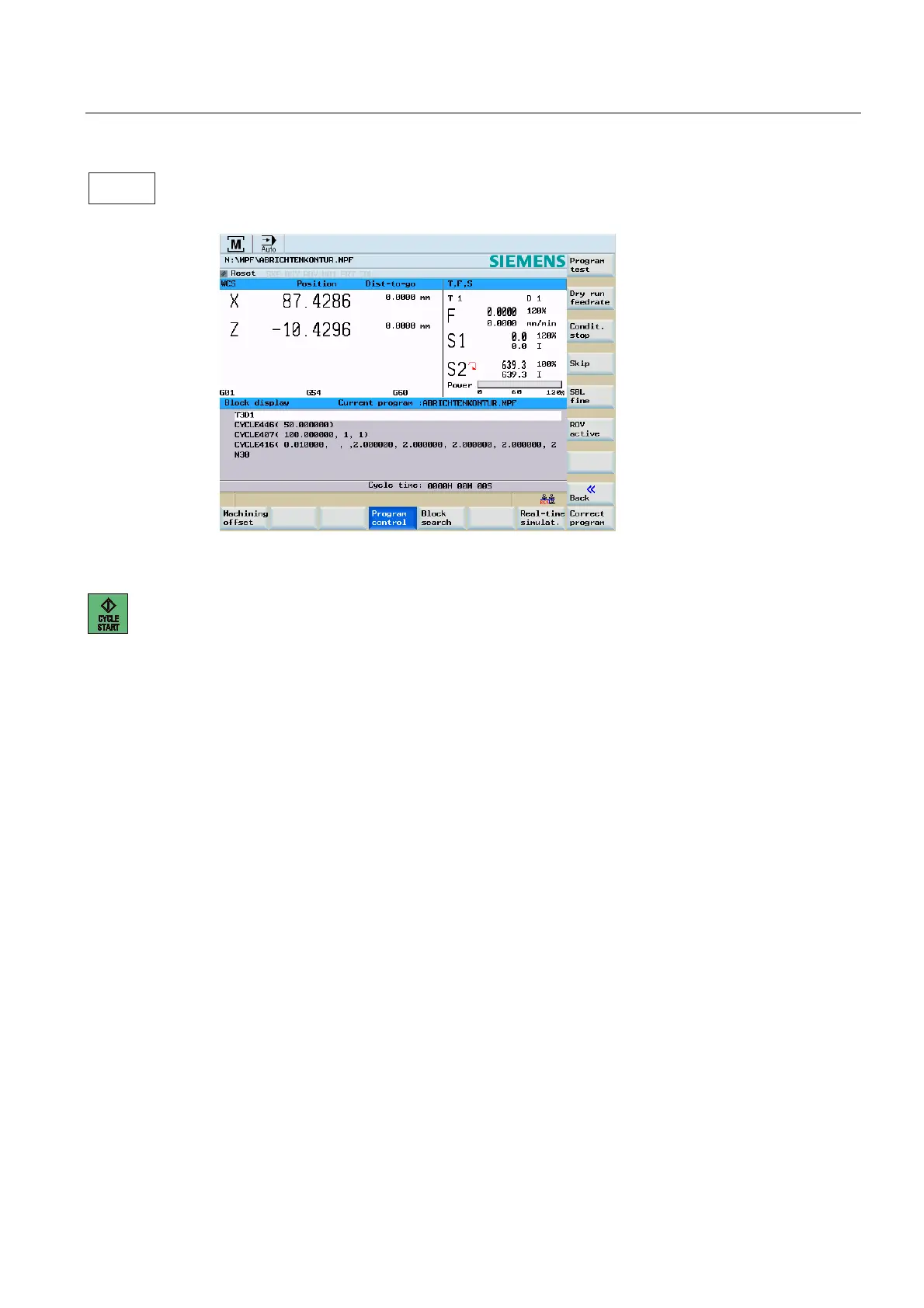

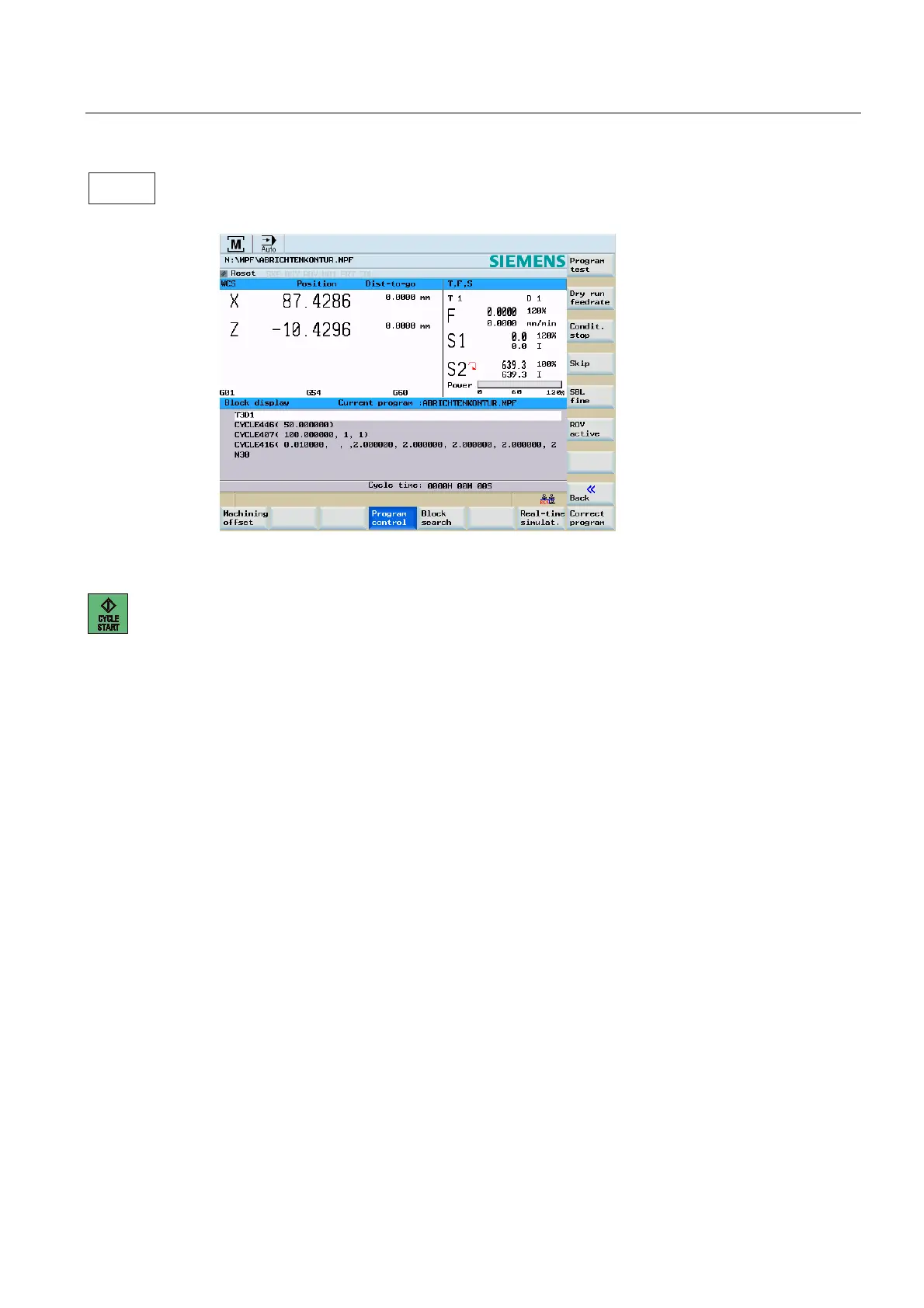

If desired, here you can specify how you want the program to be executed.

Figure 6-6 Program control

Press "NC START" to start executing the part program.

3URJUDP

FRQWURO

Loading...

Loading...