Examples

Example 1: Milling

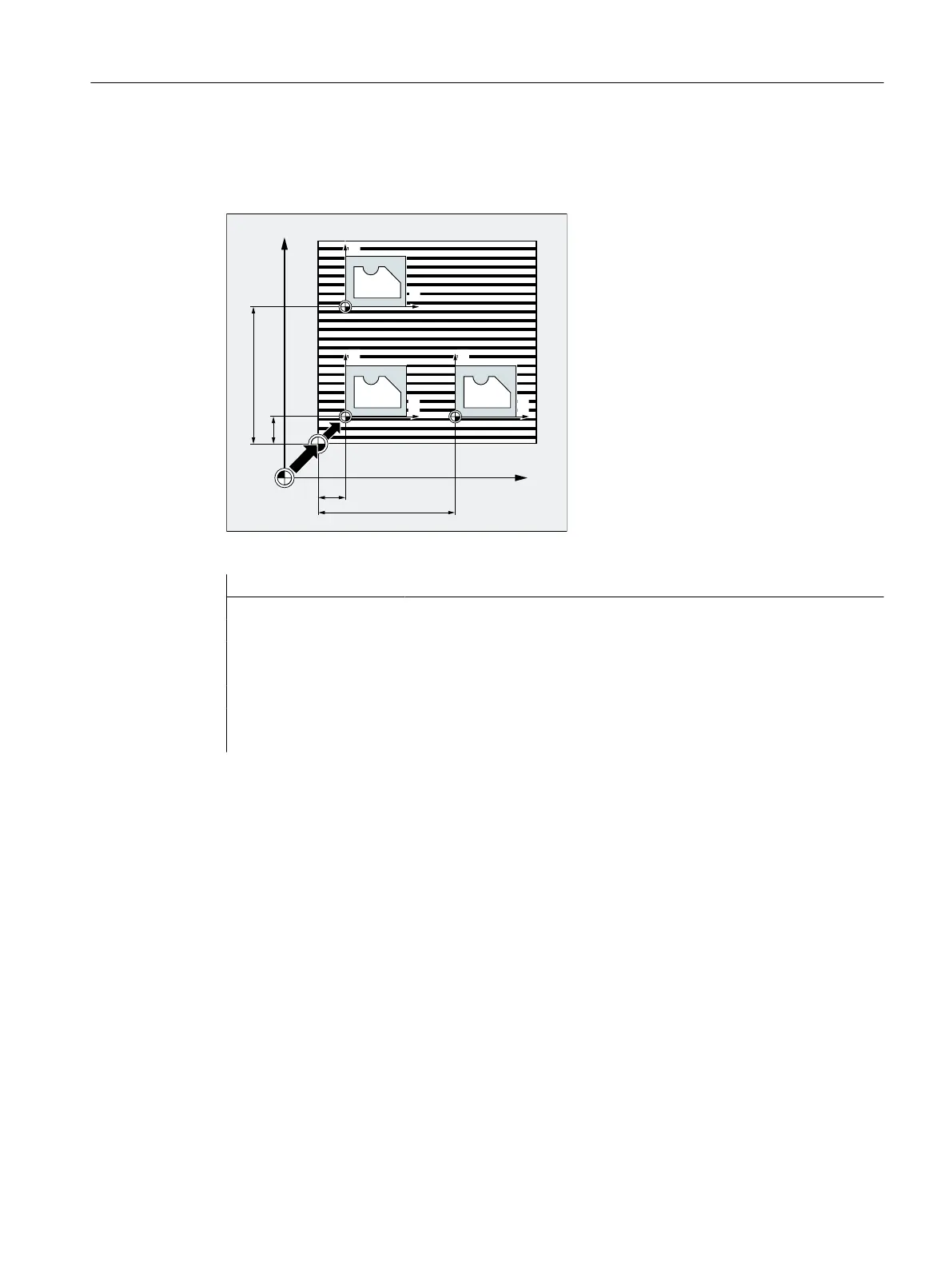

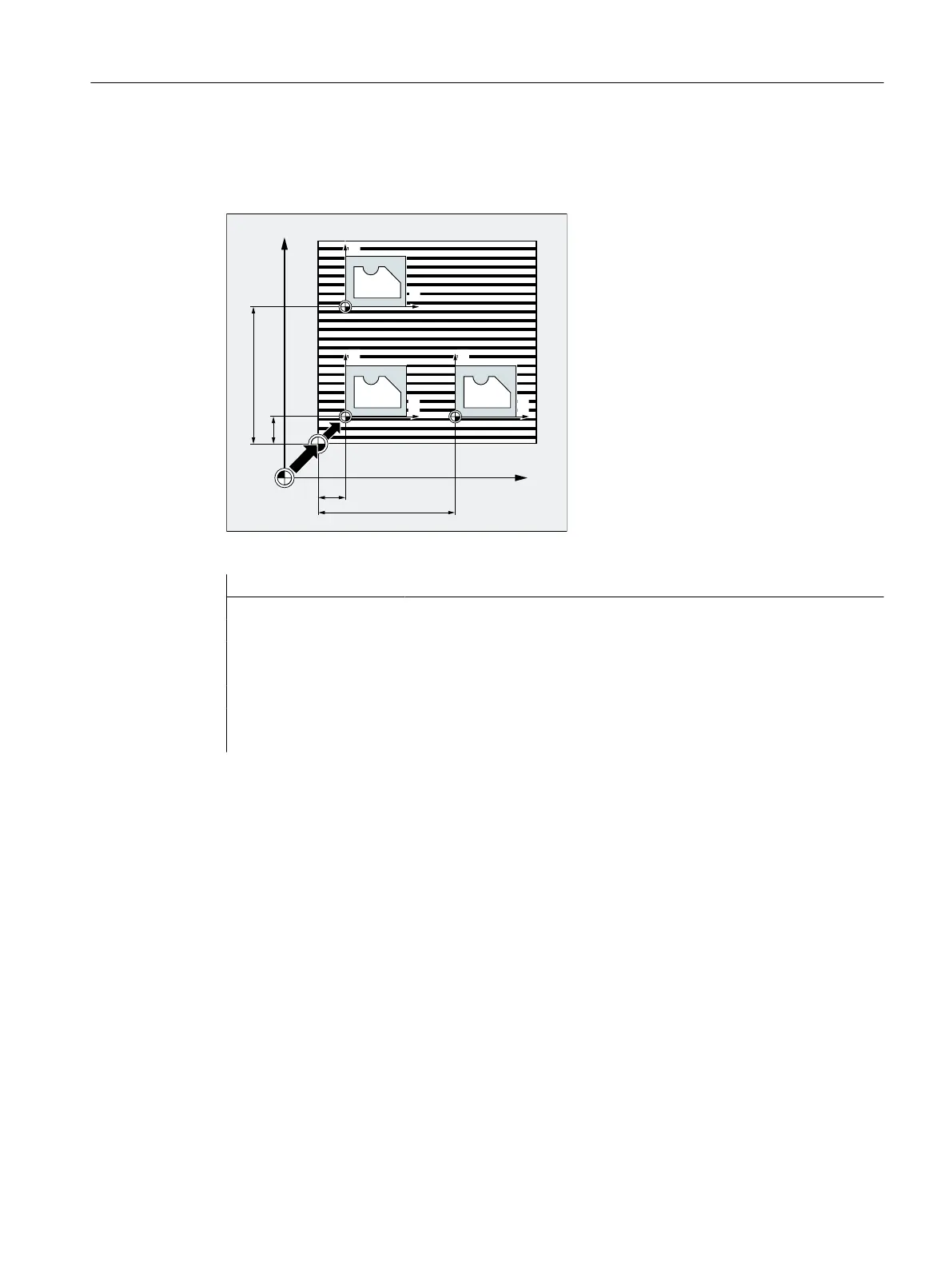

With this workpiece, the shapes

shown recur in a program.

The machining sequence for this

shape is stored in a subprogram.

Zero offset is used to set the work‐

piece zeros required in each case

and then call the subprogram.

Program code Comment

N10 G1 G54 ; Working plane X/Y, workpiece zero

N20 G0 X0 Y0 Z2 ; Approach starting point

N30 TRANS X10 Y10 ; Absolute offset

N40 L10 ; Subprogram call

N50 TRANS X50 Y10 ; Absolute offset

N60 L10 ; Subprogram call

N70 M30 ; End of program

Fundamentals

2.12 Coordinate transformations (frames)

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 311

Loading...

Loading...