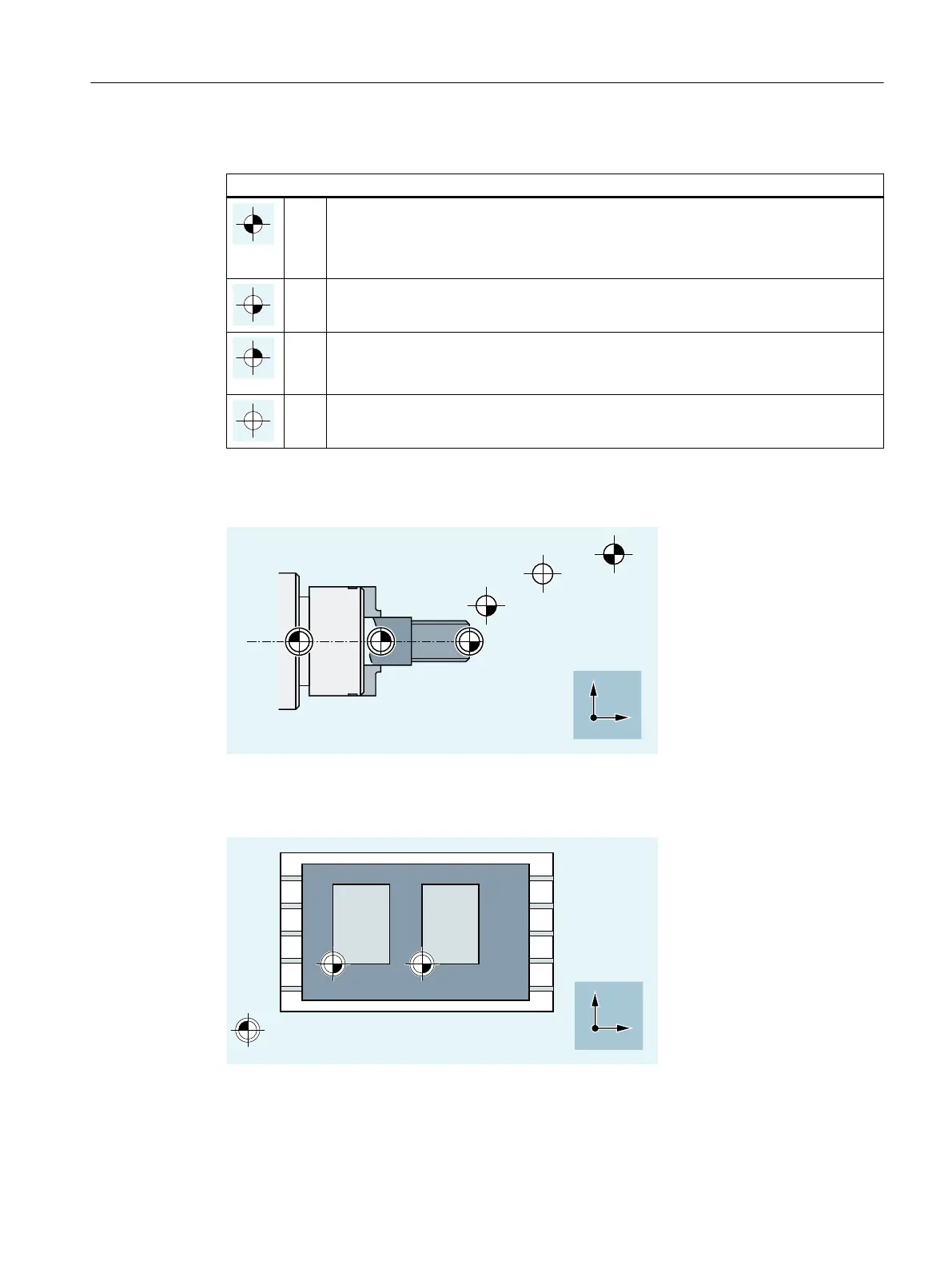

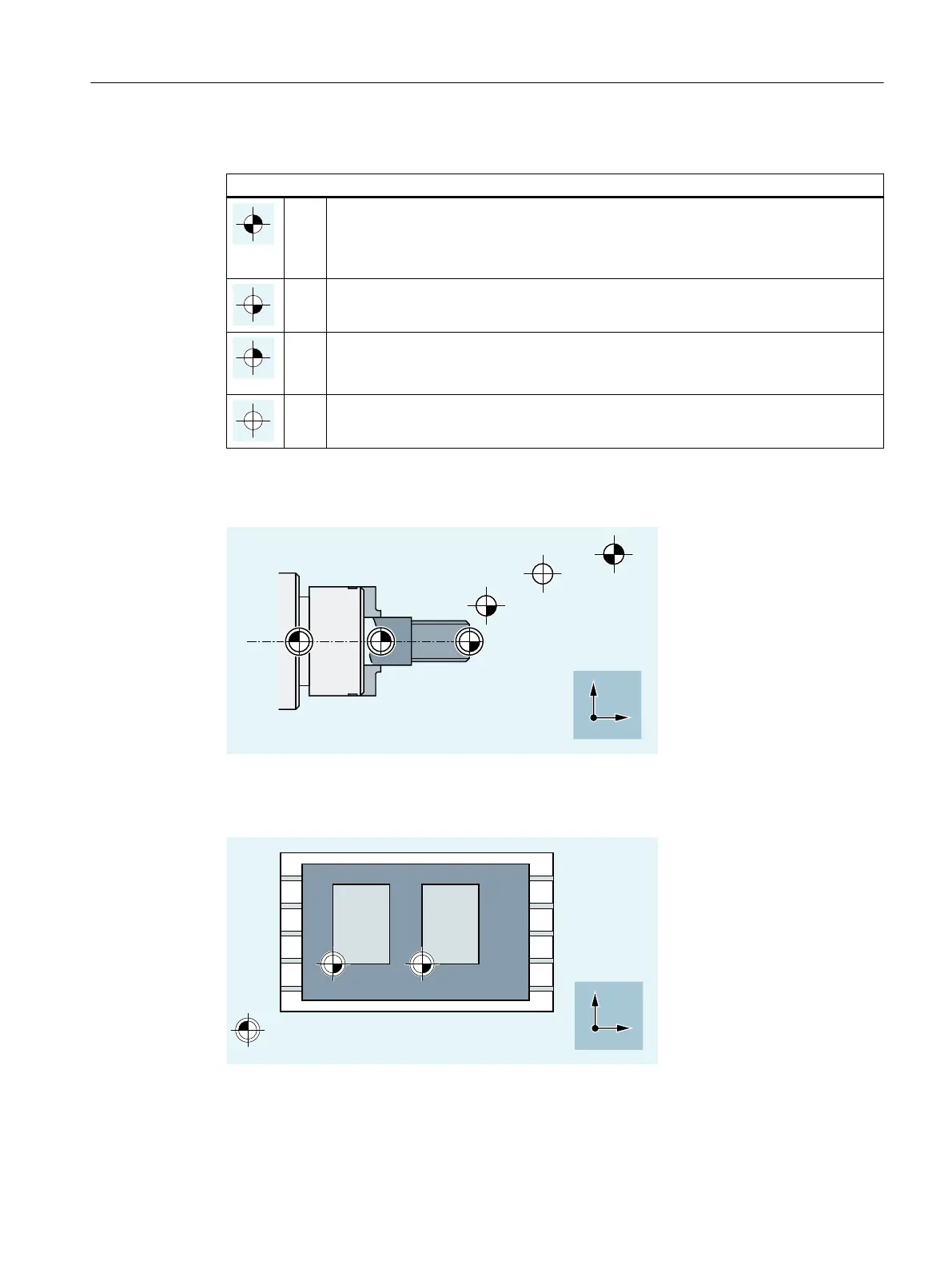

Reference points

R Reference point

Position defined by output cam and measuring system. The distance to the machine

zero M must be known so that the axis position at this point can be set exactly to this

value.

B Starting point

Can be defined by the program. The 1st tool starts machining here.

T Toolholder reference point

Is on the toolholder. By entering the tool lengths, the control calculates the distance

between the tool tip and the toolholder reference point.

N Tool change point

Zero points and reference points for turning

Zero points for milling

Fundamentals

2.1 Fundamental Geometrical Principles

NC programming

Programming Manual, 12/2019, 6FC5398-2EP40-0BA0 35

Loading...

Loading...