Detailed description

2.4 Referencing with incremental measurement systems

Basic logic functions: Reference Point Approach (R1)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

19

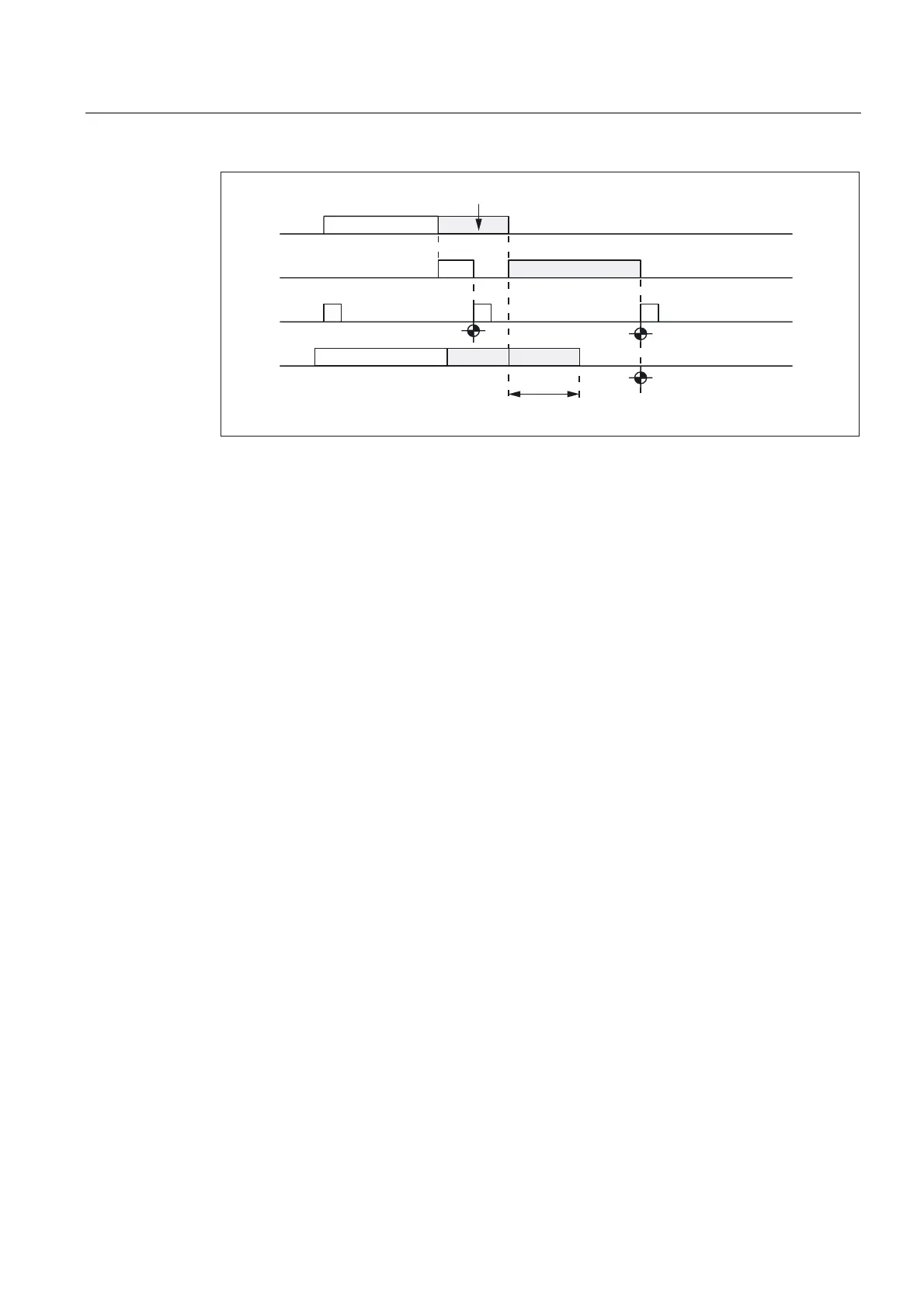

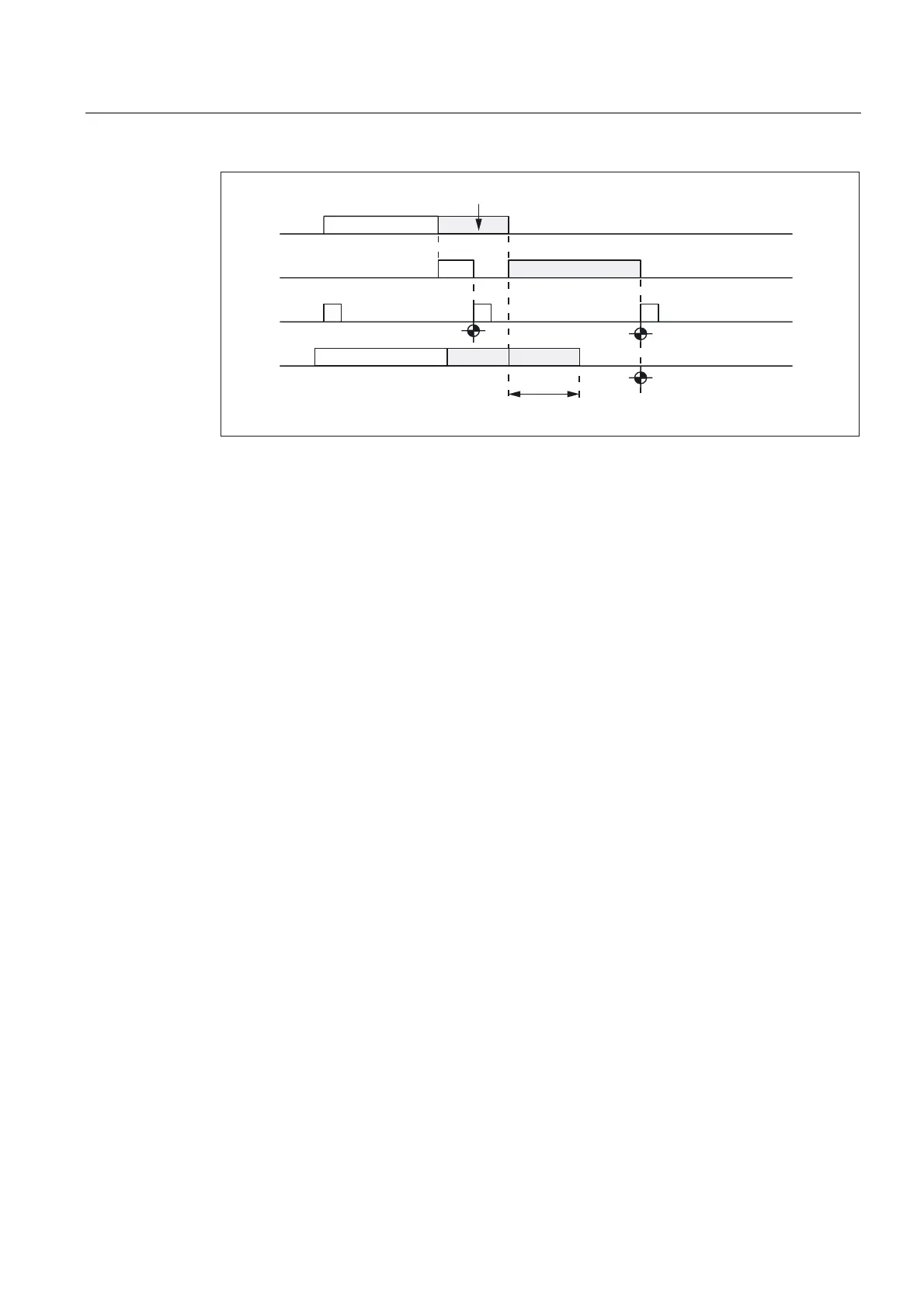

7KHUPDOH[SDQVLRQ

&DPVLJQDO

=HURPDUNVHDUFK

=HURPDUN

&DPVLJQDOZLWK

RIIVHW

0'0$B5()3B&$0B6+,)7

Figure 2-7 Electronic reference cam offset

Reference cam adjustment

Encoder with equidistant zero marks

Always ensure that the reference cam of encoders that supply zero marks at equidistances

is accurately adjusted so that the correct zero mark is always detected during reference point

approach.

Dynamic response

The following factors influence the dynamic response from the arrival of the reference cam to

the machine up to the detection of reference cam signals transferred from the PLC user

program to the NC:

• Switching accuracy of the reference cam switch

• Delay of the reference cam switch (NC contact)

• Delay at the PLC input

• PLC cycle time

• Cycle time for updating the VDI interface

• Interpolation cycle

• Position control cycle

Setting notes

• reference cam

Aligning the signal edge of the reference cam directly between two zero marks has

proven to be the most practical method.

• Electronic reference cam offset

Information needed for parameterizing the electronic reference cam offset is to be found

in the read-only machine data:

MD34093 $MA_REFP_CAM_MARKER_DIST (distance between reference cam/reference

mark)

Loading...

Loading...