Detailed description

2.3 Setpoint /actual-value system

Basic logic functions: Velocities, Setpoint/Actual Value Systems, Closed-Loop Control (G2)

Function Manual, 11/2006, 6FC5397-0BP10-2BA0

51

For the following machine data, the control does not consider any parameter set nor any

indices for coded encoders.

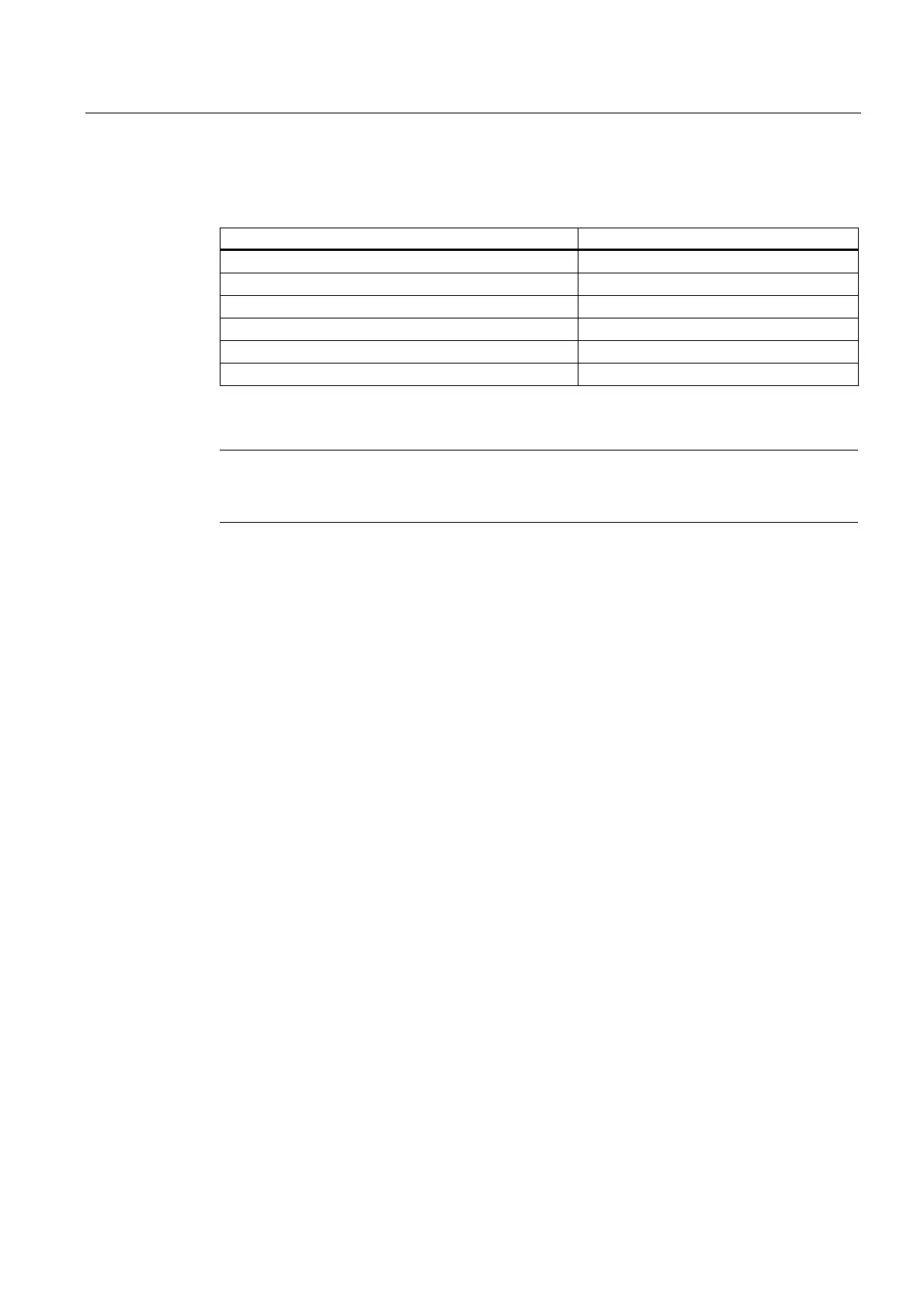

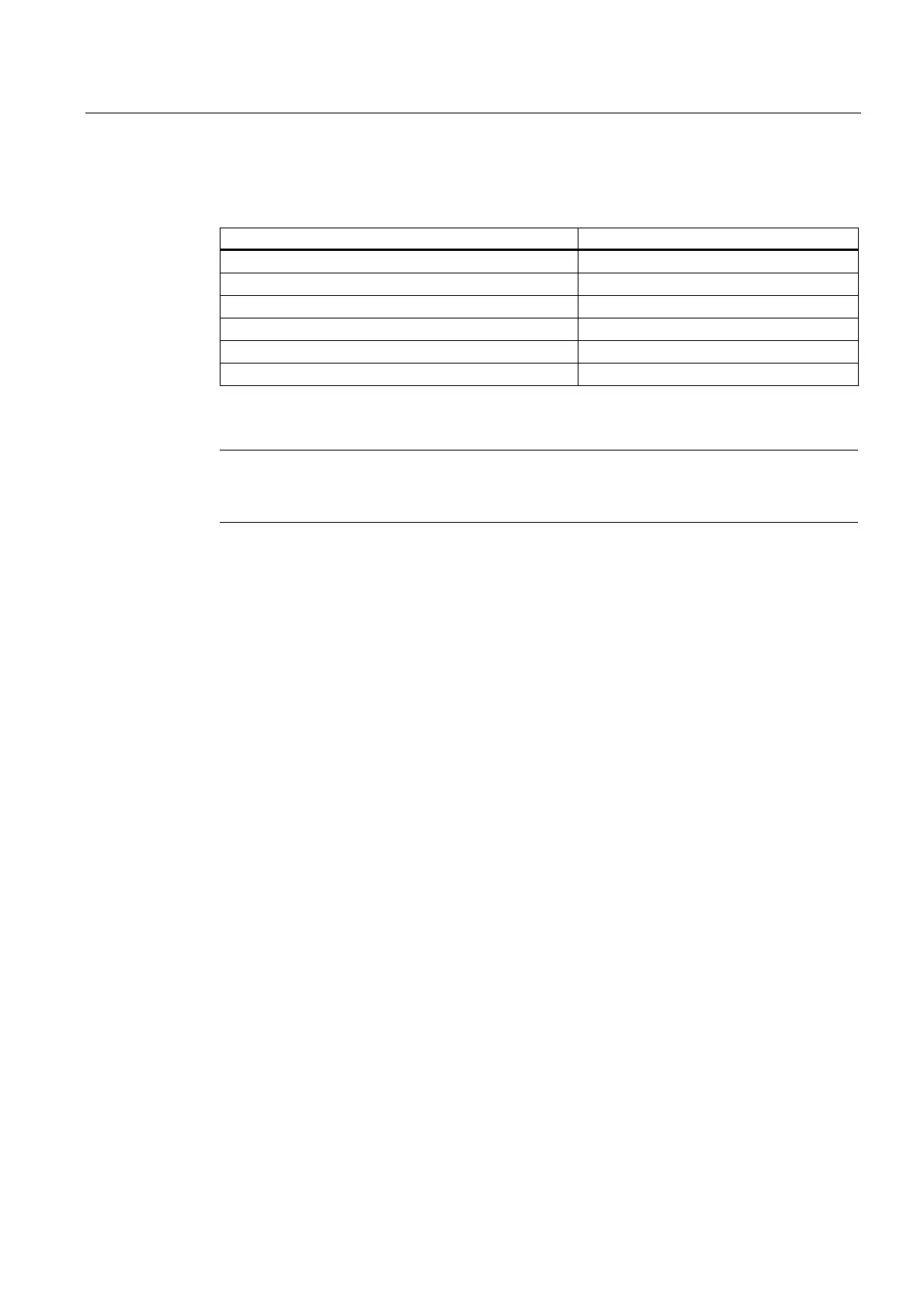

NewConfig-dependent machine data Description

MD31064 $MA_DRIVE_AX_RATIO2_DENOM (Intermediate gear denominator)

MD31066 $MA_DRIVE_AX_RATIO2_NUMERA (Intermediate gear numerator)

MD31044 $MA_ENC_IS_DIRECT2 (Encoder on intermediate gear)

MD32000 $MA_MAX_AX_VELO (Maximum axis velocity)

MD34080 $MA_REFP_MOVE_DIST (Reference point distance)

MD34090 $MA_REFP_MOVE_DIST_CORR (Reference point offset)

Note

These machine data can be activated in parts programs with the command NEWCONF or via

the HMI operator panel using a soft key.

Variants of actual-value acquisition

The relevant machine data and relational calculations for the different methods of actual-

value acquisition are described in the following.

Loading...

Loading...