2

10.04 Operation

2.13 Tools and tool offsets

2

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 2-147

2.13.6 Tool offsets

Why use tool offsets?

You do not have to take tool diameters and lengths into account when

writing machining programs.

You can program workpiece dimensions directly, e.g. as specified in

the production drawing.

When machining a workpiece, the tool paths are controlled according

to the tool geometry such that the programmed contour can be

machined using any tool.

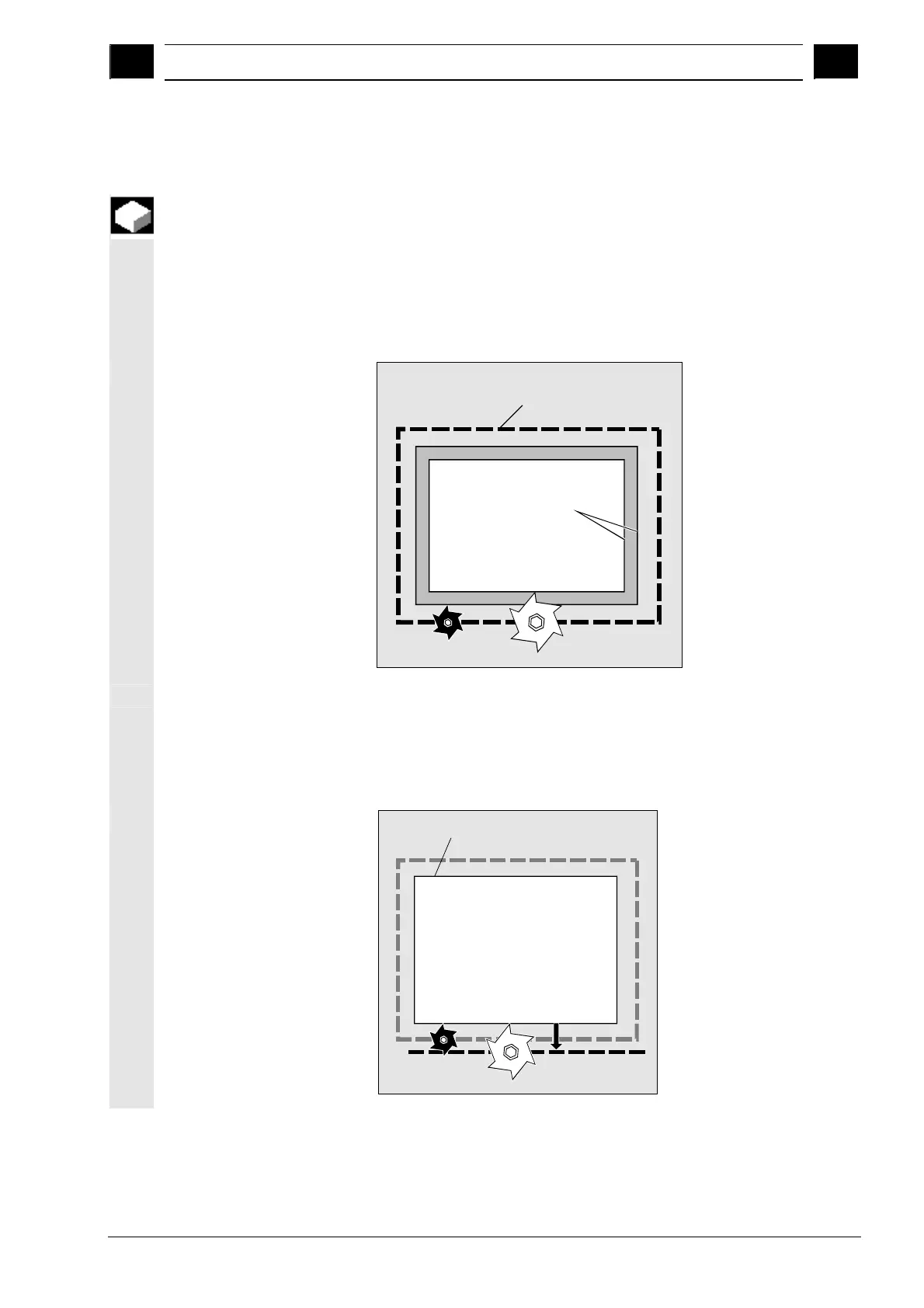

Tool path

Contour

The control corrects

the travel path

Enter the tool data separately in the "Tool list" and "Tool wear" tables.

When writing the program, you only need to call the tool you require.

While the program is being processed, the control fetches the offset

data it requires from the tool table and corrects the tool path

individually for different tools.

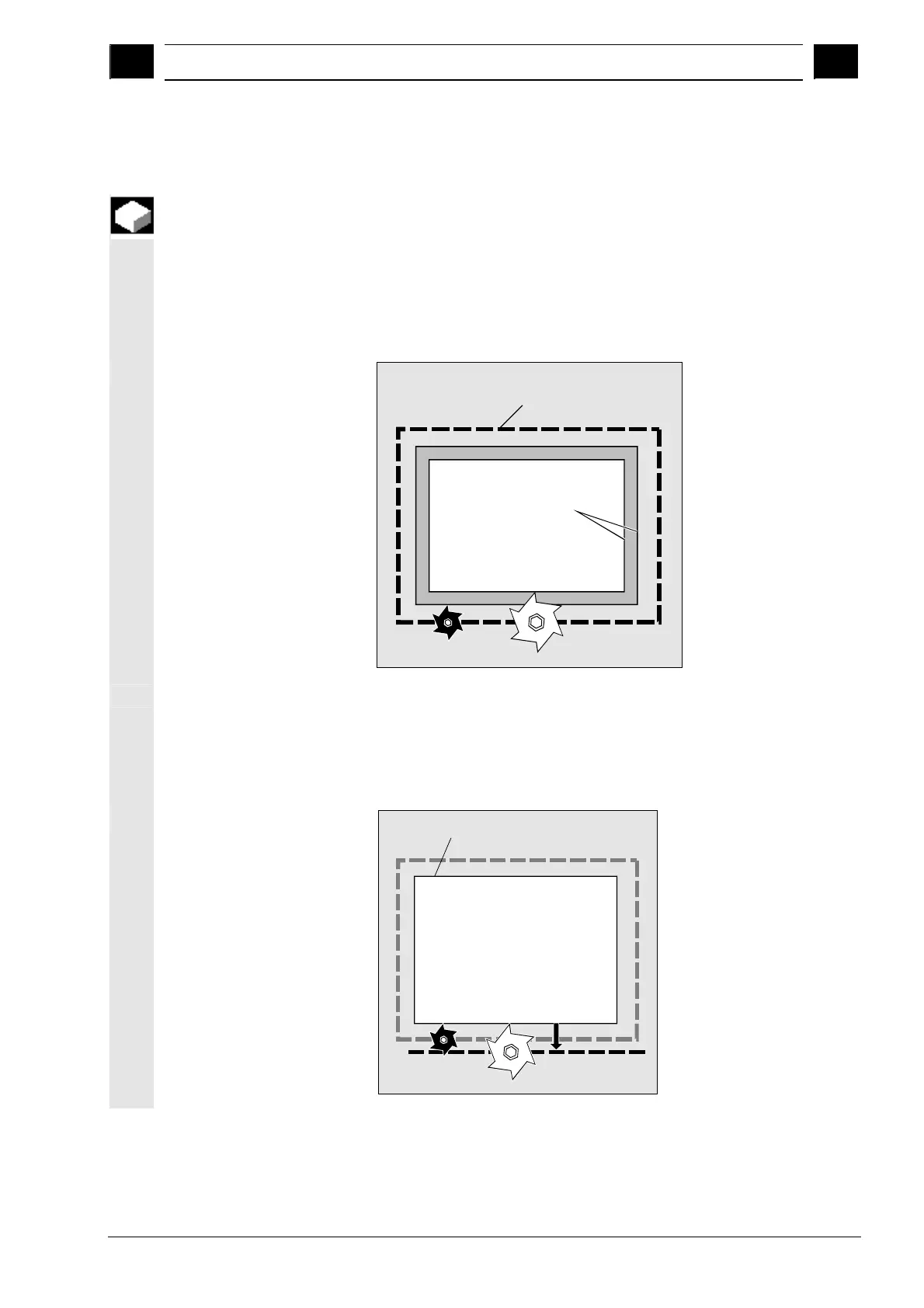

Corrected

tool path

Programmed contour

Loading...

Loading...