1

10.04 Introduction

1.2 Workstation

1

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 1-23

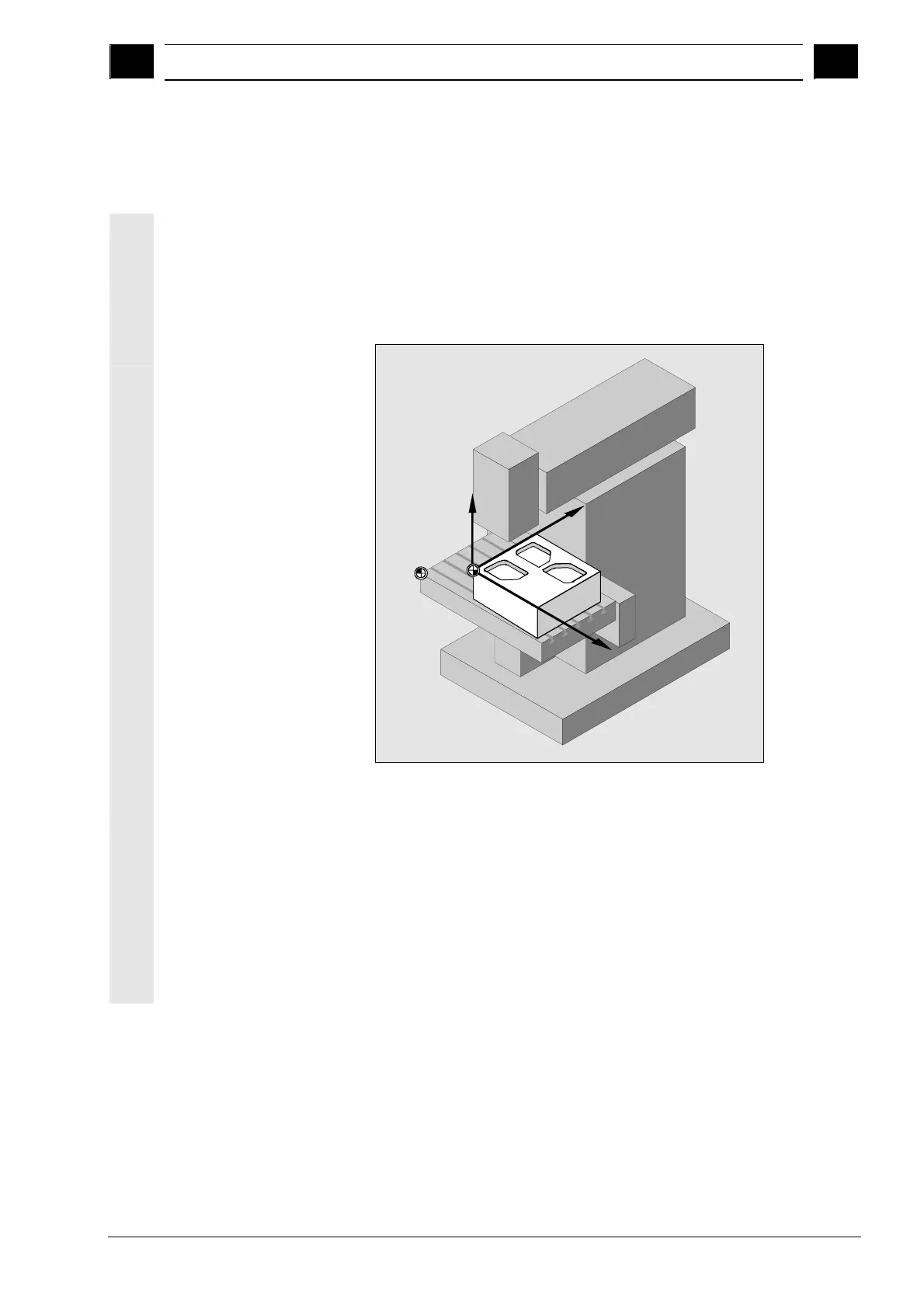

1.2.1 Coordinate system

The basic coordinate system used to machine a workpiece on a

milling machine is right-angled. It consists of the three coordinate

axes X, Y, and Z that are parallel to the machine axes.

The positions of the coordinate system and the machine zero depend

on the type of machine used.

Z

X

Y

M

W

Position of the coordinate system, machine zero and workpiece zero (example)

The axis directions are governed by the "right-hand rule" (according to

DIN 66217).

Seen from in front of the machine, the middle finger of the right hand

points in the opposite direction to the infeed of the main spindle.

Therefore:

• the thumb points in the +X direction

• the index finger points in the +Y direction

• the middle finger points in the +Z direction

Loading...

Loading...