3

10.04 Programming with ShopMill

3.7 Drillin

3

Siemens AG, 2004. All rights reserved

SINUMERIK 840D/840Di/810D Operation/Programming ShopMill (BAS) – 10.04 Edition 3-233

3.7.3 Deep-hole drilling

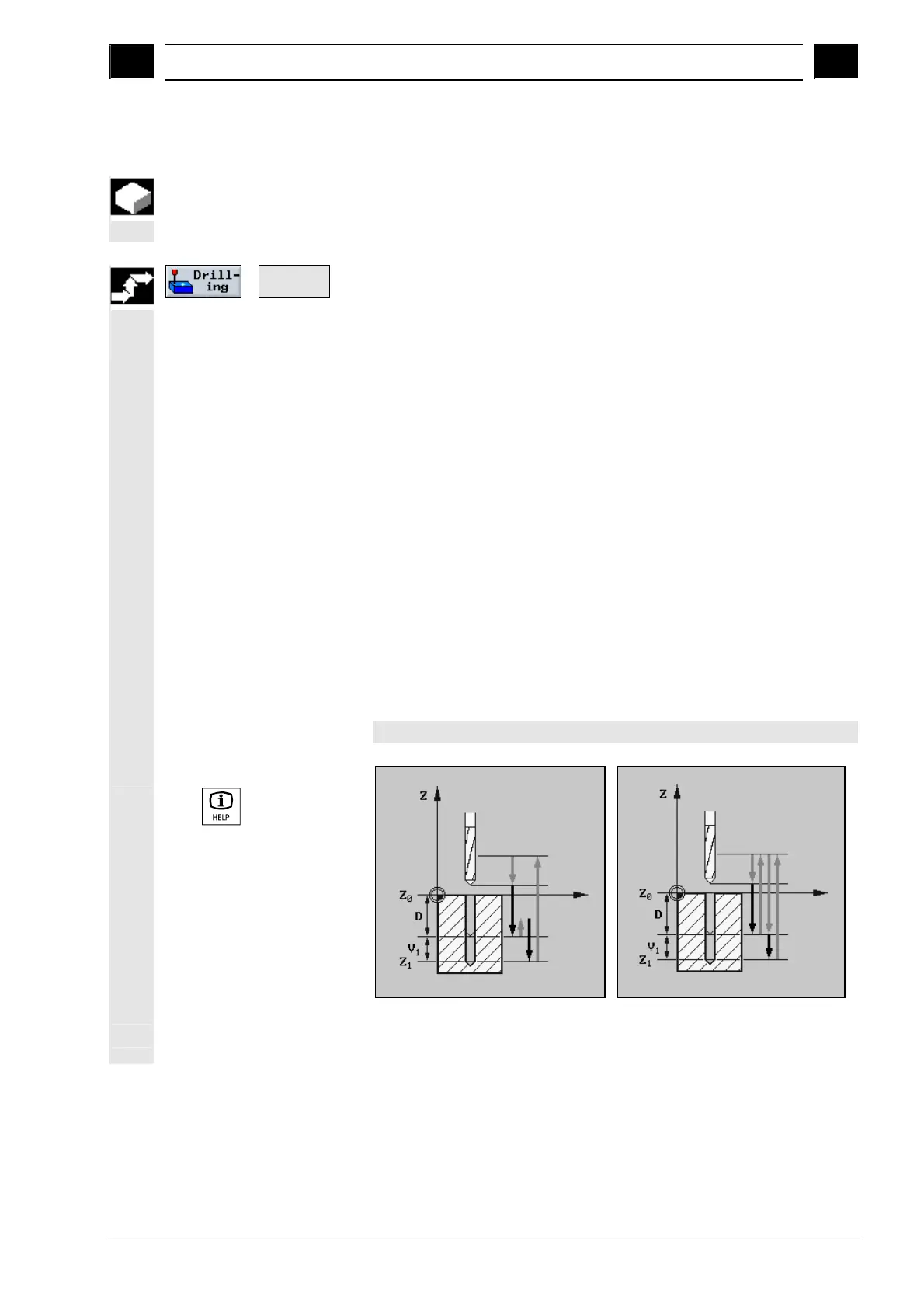

The tool is moved at rapid traverse to the programmed position,

allowing for the retraction plane and safety clearance. It is then

inserted into the workpiece at the programmed feedrate.

Deep hole

drilling

Press the "Drilling" and "Deep hole drilling" softkeys.

Stock removal

The tool drills at the programmed feedrate (F) until the 1st infeed

depth is reached. On reaching the 1st depth, the tool is retracted from

the workpiece at rapid traverse for stock removal and is then re-

inserted at the 1st infeed depth reduced by a clearance distance (V3).

The tool then drills to the next infeed depth and is then retracted

again, repeating this process until the final drill depth (Z1) is reached.

On expiry of the dwell time (DT), the tool is retracted at rapid traverse

to the safety clearance.

Chipbreaking

The tool drills at the programmed feedrate (F) until the 1st infeed

depth is reached. Once this depth is reached, the tool is retracted by a

withdrawal distance (V2) for chip breaking and is then inserted again

down to the next drilling depth. It repeats this process until the final

drilling depth (Z1) is reached.

The specified amount can be defined either per machine data or in the

parameter screenform. If the parameter is pre-assigned via machine

data, it does not appear in the parameter screen.

Please refer to the machine manufacturer's instructions.

Call help display with

the

key

Help display for deep hole drilling with

chipbreaking

Help display for deep hole drilling with stoc

removal

Loading...

Loading...