TB20J Plus Operation Manual

55

© Feb. 2023

10 MAINTENANCE

This chapter provides the operator with the additional in-

formation needed to properly operate and maintain the

machine and is only intended to assist the operator in

performing routine maintenance tasks. For more com-

prehensive maintenance instructions, please refer to the

Inspection and Preventive Maintenance Schedule

and the Maintenance Manual.

10.1 LUBRICATION

In order to ensure the performance and service life of

the machine and its components, the moving parts must

be regularly inspected and lubricated.

NOTICE

• Mixing lubricating oil of different grades will

change its property, and bring damage to the ma-

chine. When adding lubricating oil, the oil to be

added must have the same grade as that of the oil

being used by the machine.

• Using lubricating oil mixed with dust can lead to

premature wear of the sliding surfaces and short-

en the service life of the machine. Before adding

lubricating oil, the oil cup and other surfaces must

be cleaned.

• Failure to comply with lubrication intervals or lack

of lubrication can cause machine damage and in-

crease repair costs and downtime.

• During machine lubrication, unrelated person-

nel are prohibited from operating the machine,

because accidental operation of the machine

may bring serious danger to the operator.

• If lubricating oil gets into the eyes, rinse the

eyes immediately with clean water and seek

medical attention in time. If the skin comes into

contact with lubricating oil, make sure to thor-

oughly wash the skin with water.

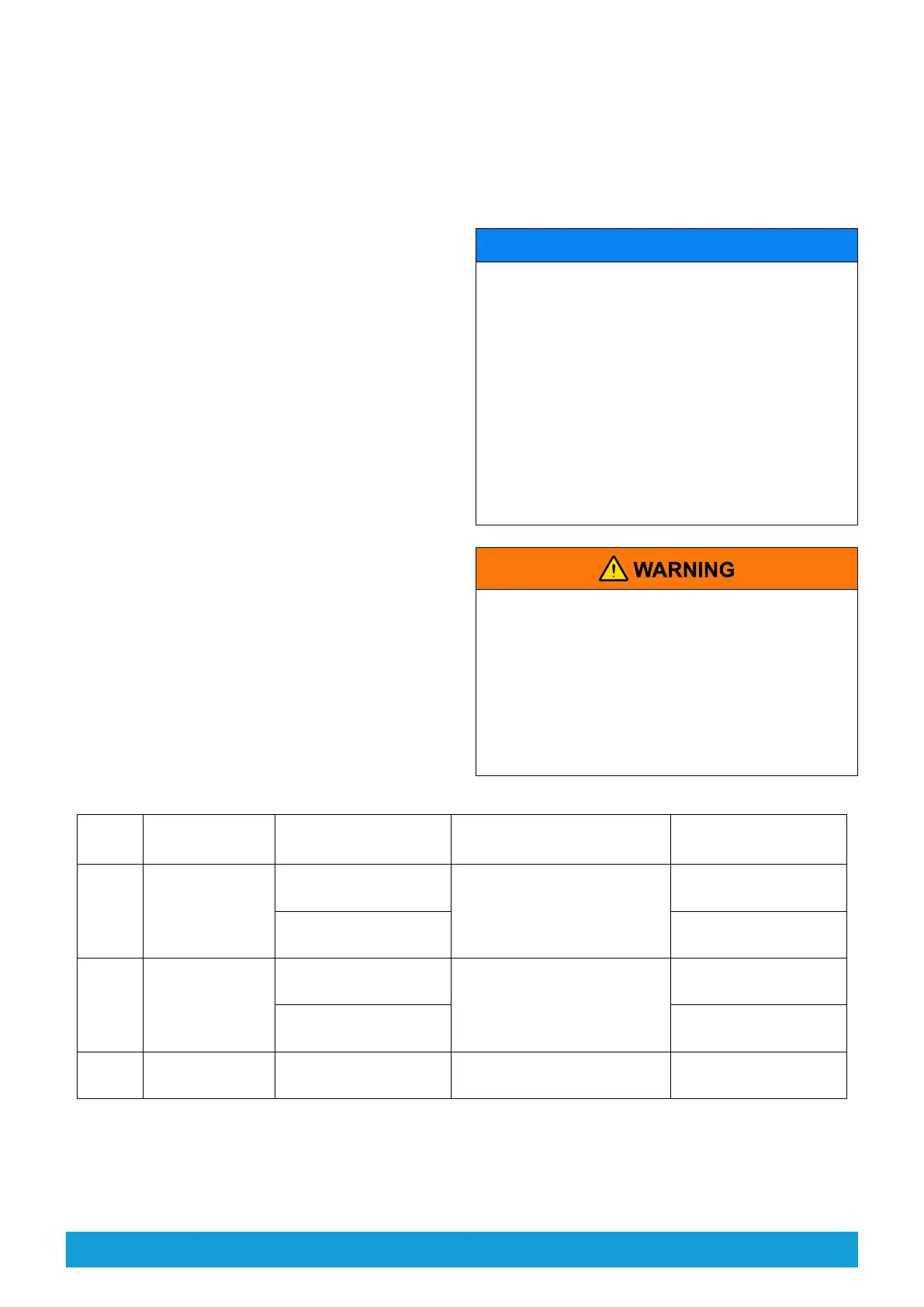

Table 10-1

No. Position Interval

Lubricating oil/grease

grade

Operation

1

Travel drive

device

Every 3 months or 250

working hours

90# industrial gear Oil

Check oil level

Every 1 year or 1000

working hours

Replace oil

2

Rotation drive

device

Every 3 months or 250

working hours

90# industrial gear Oil

Check oil level

Every 1 year or 1000

working hours

Replace oil

3

Rotation support

Every 3 months or 250

working hours

ZL-3 lithium-based lubricating

grease

Add oil with oil gun

Lubrication intervals are based on machine usage under

normal operating conditions, and if the machine is used

in harsh conditions (such as dusty environments) or ab-

normal conditions, the inspection and lubrication should

be performed more frequently.

Loading...

Loading...