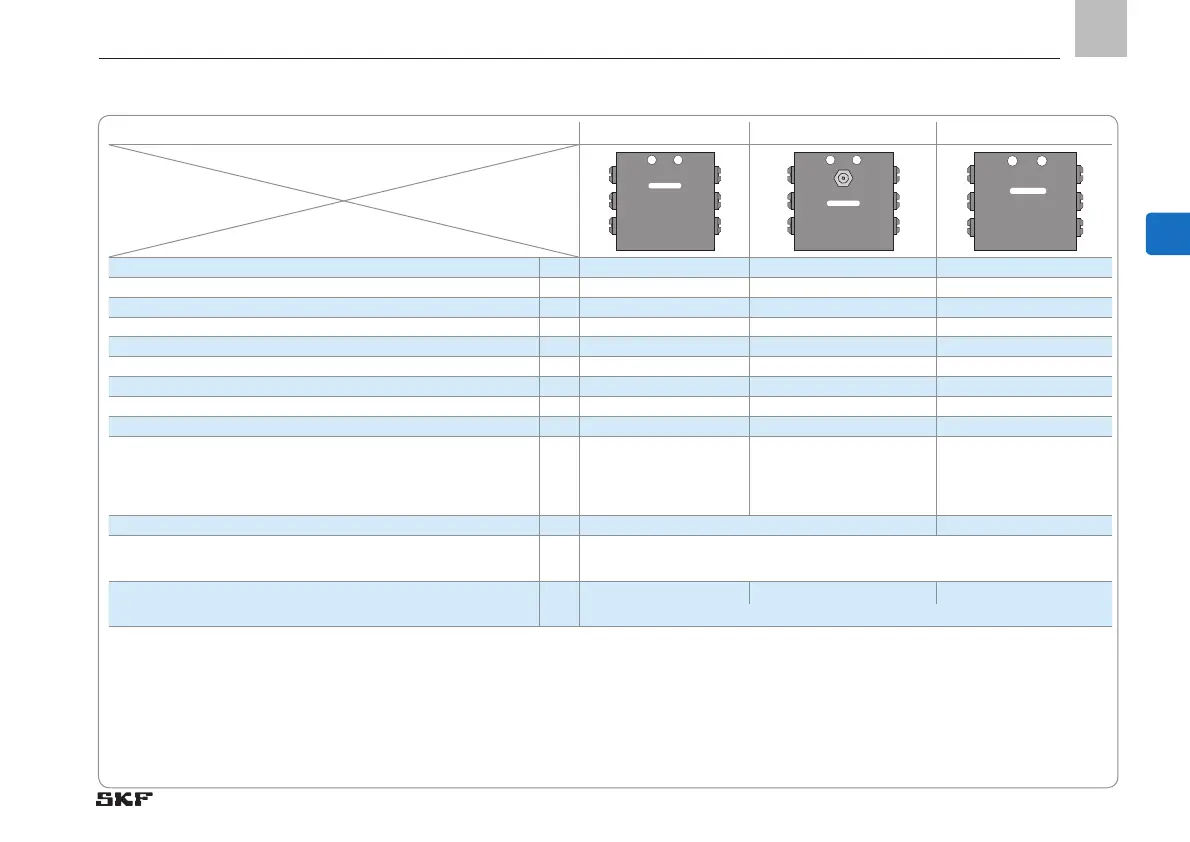

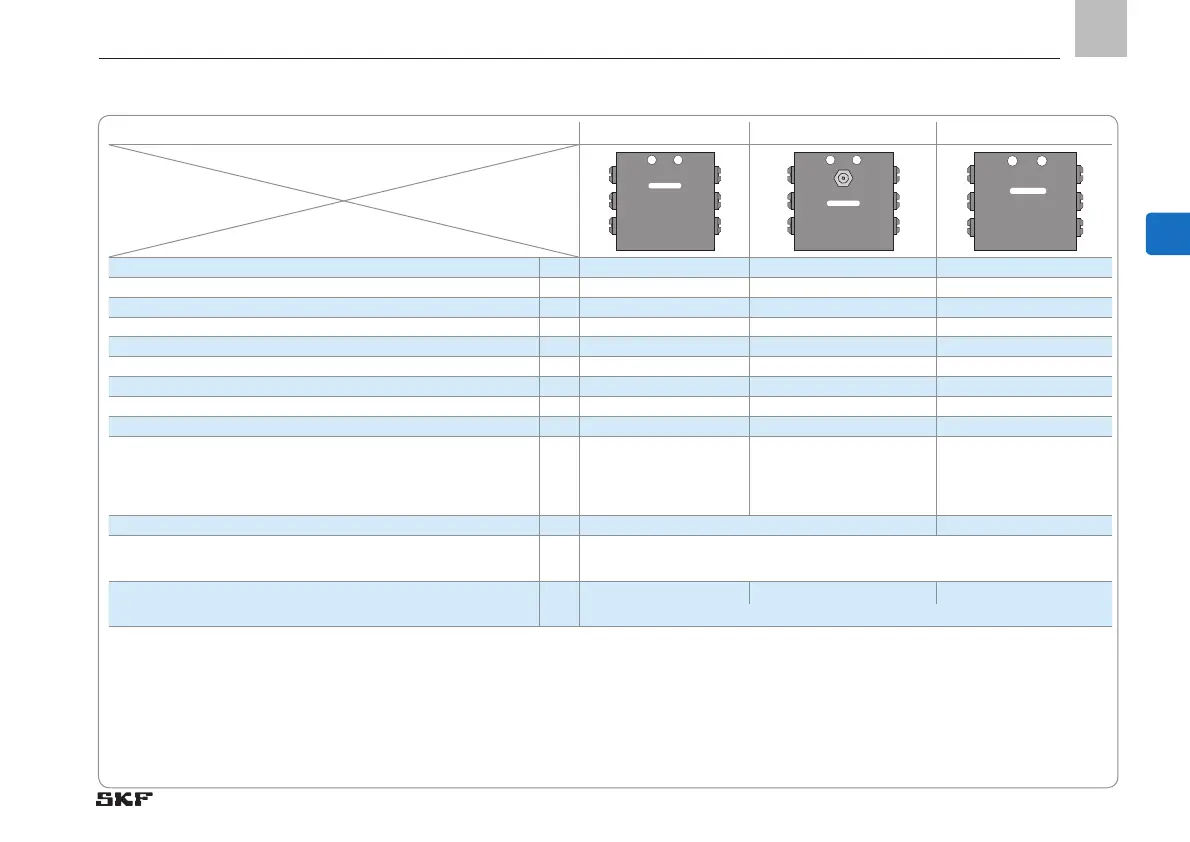

4.1 Technical data SSV/SSV-E/SSVM

SSV SSV-E SSVM

6

4

21

3

5

MADE IN XXXXXXX

SSV

XXXXXXX

LINCOLN

An SKF Group Brand

6

4

21

3

5

MADE IN XXXXXXX

LINCOLN

An SKF Group Brand

SSV-E

XXXXXXX

MADE IN XXXXXXX

LINCOLN

An SKF Group Brand

1

3

5

6

4

2

SSVM

XXXXXXX

Maximum operating pressure bar 350 350 200

Minimum operating pressure bar 20 20 20

5)

Max. differential pressure between 2 outlets bar 100 100 40

Number of outlets 6-22 6-22 6-12

Installation position any any

1)

any

Inlet thread G1/8 G1/8 G1/8

Outlet thread M10 x 1 M10 x 1 M8 x 1

Connectable lubrication lines mm Ø 4 | Ø 6 Ø 4 | Ø 6 Ø 4

2)

Metering volume per stroke and outlet cm

3

0.2 0.2 0.07

Possible material versions

Steel, black zinc-coated

Steel, chemically nickel-plated

Stainless steel 1.4305 (V2A)

Stainless steel 1.4571 (V4A)

Steel, black zinc-coated

Stainless steel 1.4305 (V2A)

Steel, black zinc-coated

3)

Function monitoring options K | KA | KN | N | NP | KS K | KA | KN | KS

Suitable lubrication grease consistencies Lubrication greases up to and including NLGI 2

Suitable lubrication oil viscosities Lubrication oils of at least 40 mm²/s at ambient temperature

4)

Ambient temperature range without electrical component

°C

-40 to + 100 -40 to + 100 -25 to + 70

4)

Ambient temperature range with electrical component see Technical data of the respective electrical component

1)

Installation position limited by the emergency lubrication fitting.

2)

When using function monitoring devices K, KA, KN, the metering volume on those outlets provided with lubricant by a piston via indicator pin is reduced as

follows: SSV, SSV-E by about 35%, SSVM by about 25%.

3)

Also see chapter Function monitoring options

4)

The stated ambient temperature range assumes the transportability of the lubricant applied and the use of fittings and lubrication lines suitable for the

respective existing ambient temperature.

5)

The maximum differential pressure must not be exceeded and can be reduced by selecting the right length and diametre of the line.

Loading...

Loading...