271

229042ABASJ46 AJ+, SJ46 AJ, SJ51 AJ

Axles Section 5 – Procedures

9. Reinstall the cylinder fittings, torquing the larger

one to 33 Nm (24 ft-lb) and the smaller one to 20

Nm (15 ft-lb).

10. Remove the plugs and reconnect the hoses to

the cylinder fittings, torquing the larger hose end

to 28 Nm (21 ft-lb) and the smaller hose end to

16 Nm (12 ft-lb).

11. Reinstall the base cover and remove the block of

wood.

12. Turn the engine on and let it run for a few

minutes to pressurize the cylinder, then turn it off

again.

13. Check the oil level using the hydraulic tank sight

gauge. Add more hydraulic oil if needed.

14. Bleed the cylinder (refer to the next procedure).

5.10-8 Bleed the Oscillating Axle Cylinders

If the axle oscillation system is not operating properly,

the stability of the MEWP is compromised and it may

tip over.

Items you will need before starting:

▪

oil container

▪

hose (to reach from bleeders to bucket)

1. Locate a bleeder on either side of the oscillating

axle cylinder.

2. Connect a hose to the bleeder nipple.

3. Start the engine and slowly open the bleeder to

allow the oil to flow in a continuous stream.

4. Close the bleeder.

5. Repeat the procedure with the other oscillating

axle cylinder.

5.10-9 Test the Oscillating Axle Cylinders

1. Extend the fly boom 30 cm (1 ft) while on

a firm, level surface.

▪

Result: The steer axle should be locked.

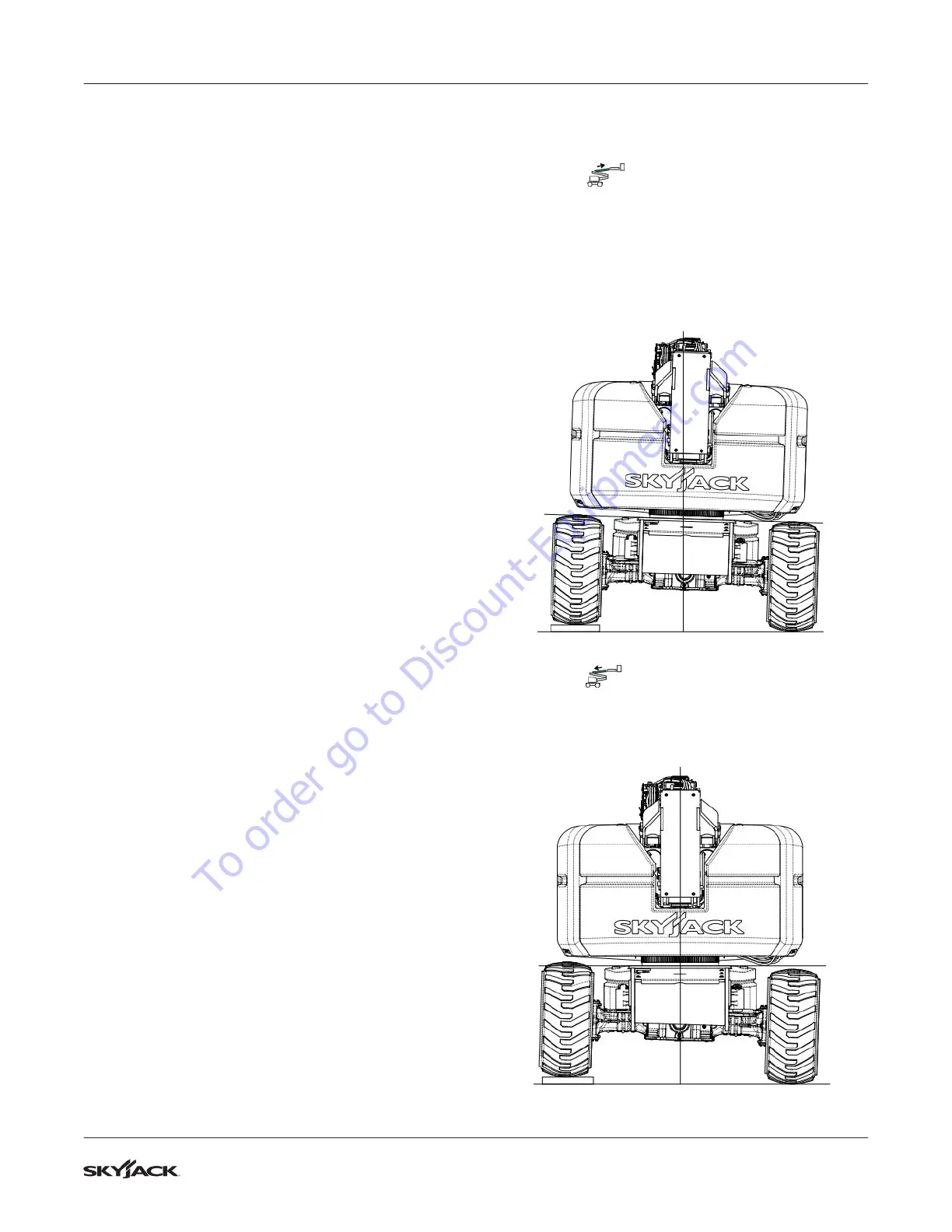

2. Drive one of the steer tires up onto a 15 cm (6")

block or curb.

▪

Result: An appropriate tilt of the MEWP

chassis should occur.

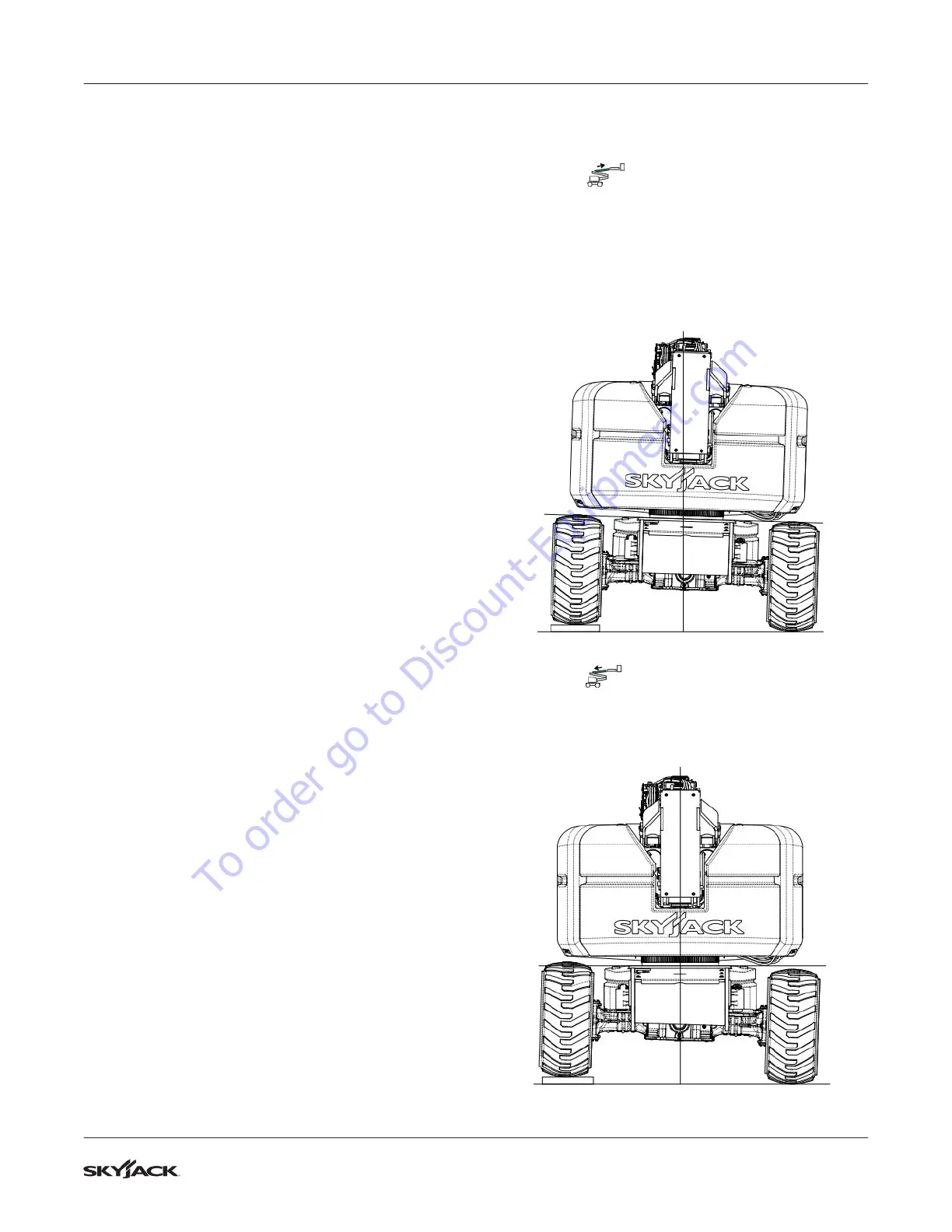

3. Retract the fly boom while in tilt position.

▪

Result: The steer axles should unlock and

the MEWP chassis should level itself to the

ground.

To order go to Discount-Equipment.com

Loading...

Loading...