SJ519 TH 216939ADA

41

Visual & Daily Maintenance Inspections Section 4 – Pre-operation

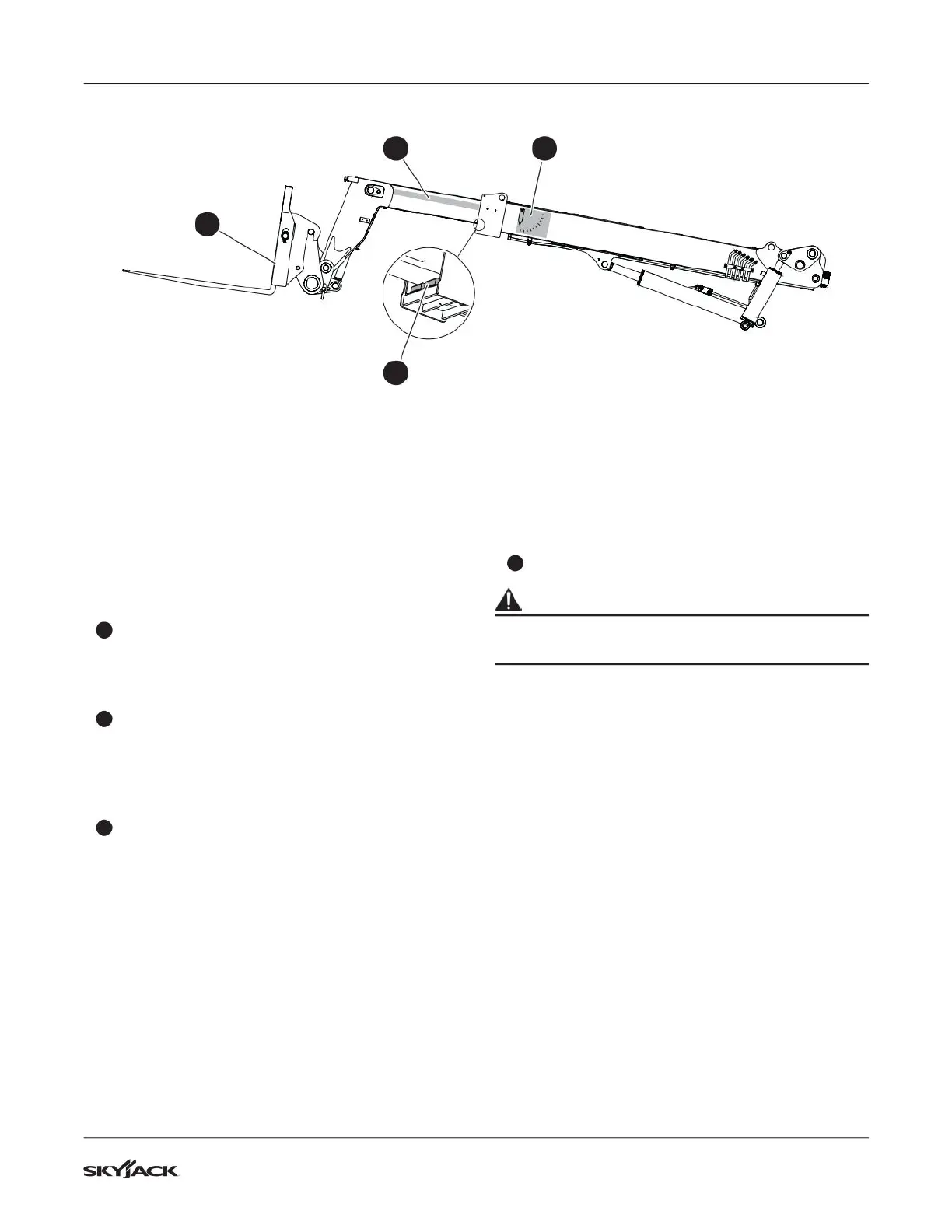

4.2-8 Boom

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure all bolts and pins are properly tightened.

▪

Ensure there are no visible cracks in welds or

structure and there are no signs of deformation.

▪

Ensure all hoses are properly tightened and

there is no evidence of hydraulic leakage.

1

Slide Pads

▪

Ensure all bolts are tight, there is no visible

damage to the slide pads and that no parts are

missing.

2

Boom Angle Indicator

▪

Ensure all bolts are tight, and there is no

visible damage and indicator swings freely.

4.2-9 Lifting Attachment

3

Ensure attachment is properly positioned and

secured. (Refer to Section 5.12).

▪

Ensure there are no loose or missing parts and

there is no visible damage.

4.2-10 Grease Points

Maintaining properly greased components is

essential for good performance and service life of the

telehandler. If components are improperly greased, it

could result in component damage.

4

Greased component locations

WARNING

Ensure that there are no personnel or obstructions

in maintenance area.

Greasing intervals are based on average telehandler

usage. Use of telehandler may vary significantly

and greasing frequency must be adjusted to obtain

maximum service life.

Refer to the Daily & Weekly Maintenance Chart

located inside operator’s cab for grease points

location and service intervals.

1

3

4 2

Loading...

Loading...