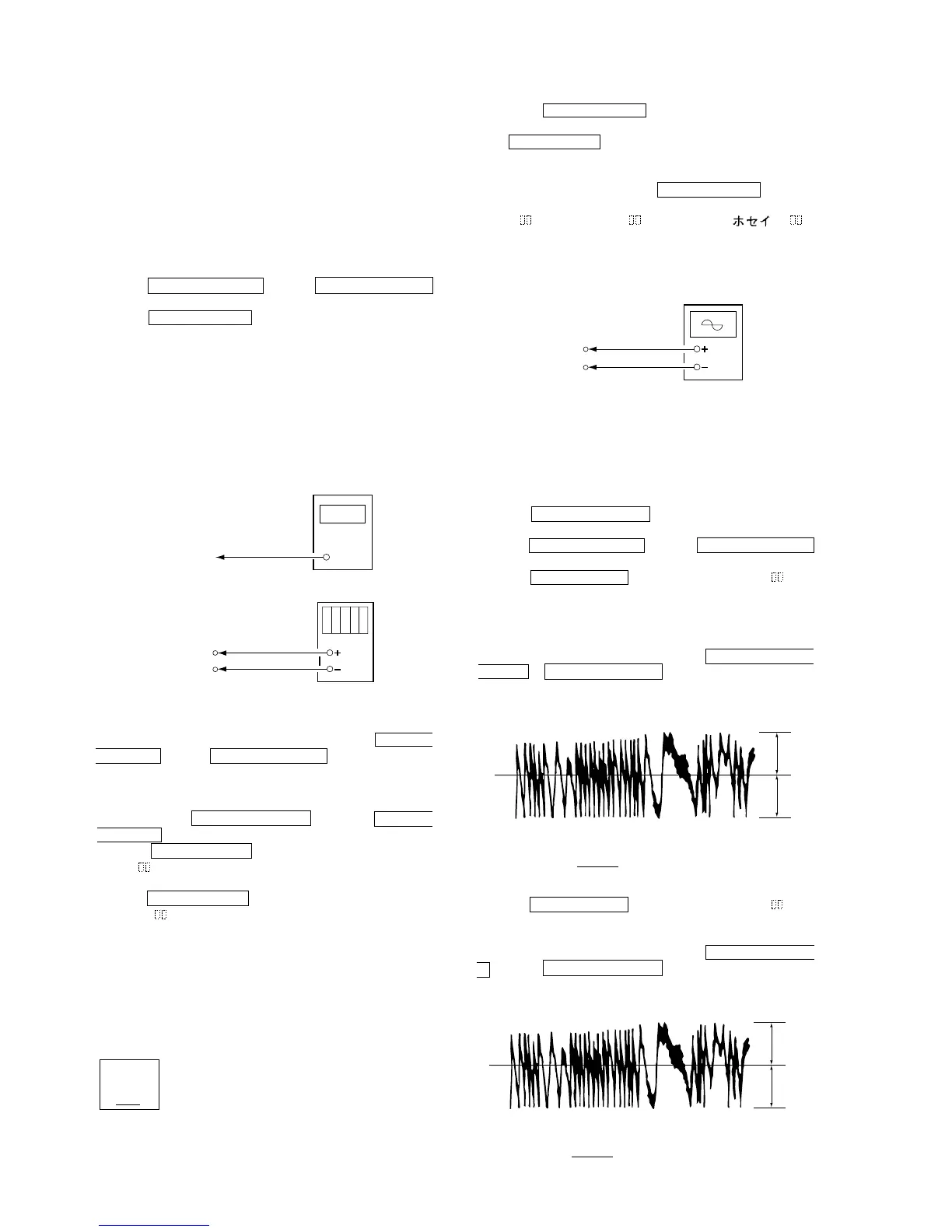

Oscilloscope

BD (MD) board

CN110 pin 3 (TE)

CN110 pin 1 (VC)

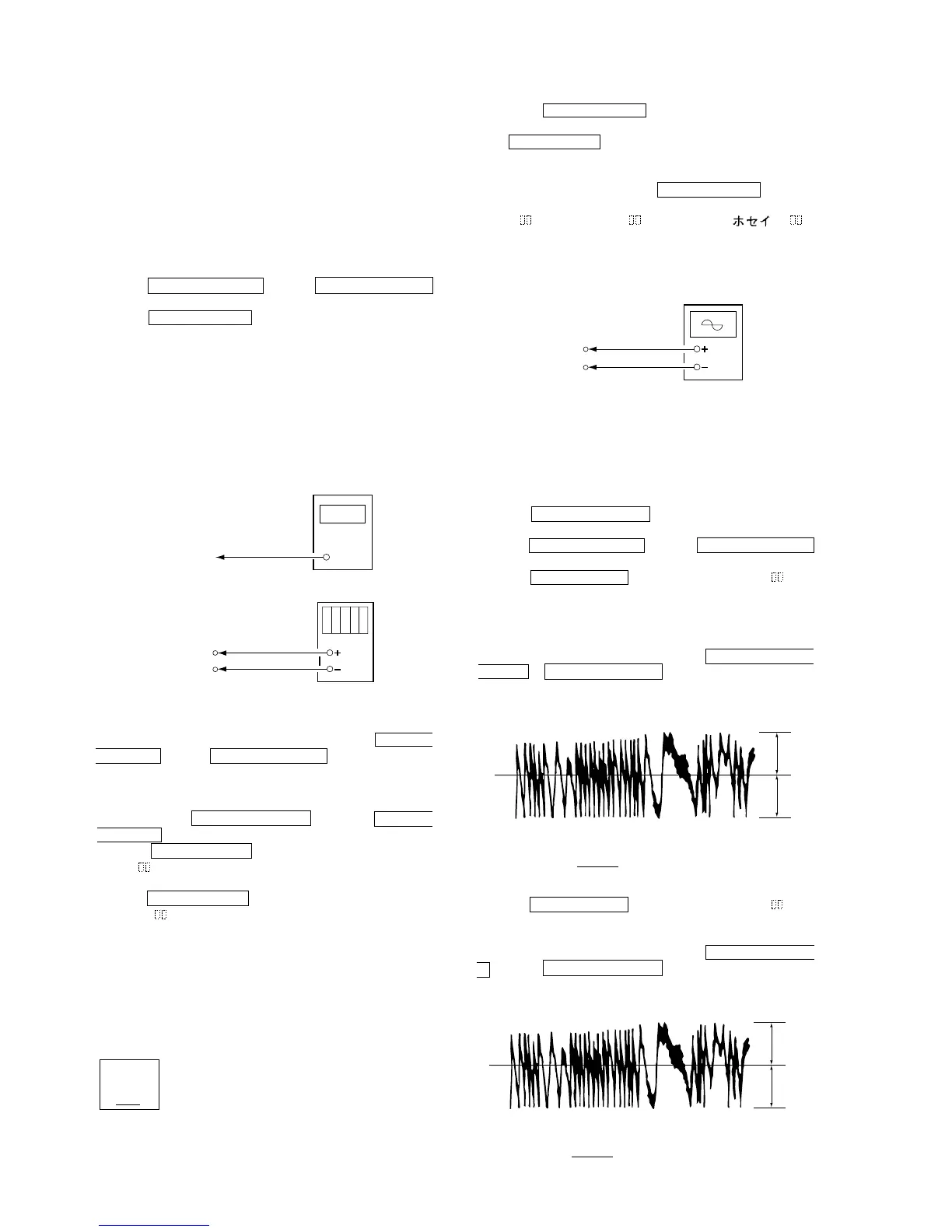

VC

A

B

Specified value : 10% or less of the offset value

Offset value (%) = X 100

IA – BI

2 (A + B)

VC

A

B

Specified value : 10% or less of the offset value

Offset value (%) = X 100

IA – BI

2 (A + B)

5-6. Checks Prior to Repairs

These checks are performed before replacing parts according to

“approximate specifications” to determine the faulty locations. For

details, refer to “Checks Prior to Parts Replacement and

Adjustments” (See page 14).

5-6-1. Temperature Compensation Offset Check

When performing adjustments, set the internal temperature and room

temperature to 22 to 28°C.

Checking Procedure:

1. Press the lm/TUNING – button or ML/TUNING +

button to display “TEMP CHECK”.

2. Press the ENTER/YES “R” button.

3. “T=@@(##) [OK]” should be displayed. If “T=@@ (##) [NG]”

is displayed, it means that the results are bad.

(@@ indicates the current value set, and ## indicates the value

written in the non-volatile memory.)

5-6-2. Laser Power Check

Before checking, check the IOP value of the optical pick-up.

(Refer to “5-8. Recording and Displaying IOP Information”.)

Connection :

Checking Procedure:

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the lm/

TUNING – button or ML/TUNING + button continuously

to move the optical pick-up.)

Connect the digital volt meter to CN110 pin 5 (I+3V) and

CN110 pin 4 (IOP).

2. Then, press the lm/TUNING – button or ML/

TUNING + button and display “LDPWR CHECK”.

3. Press the ENTER/YES “R” button once and display “LD 0.9

mW $ ”. Check that the reading of the laser power meter

become 0.84 to 0.92 mW.

4. Press the ENTER/YES “R” button once more and display “LD

7.0 mW $ ”. Check that the reading of the laser power meter

and digital volt meter satisfy the specified value.

Specified Value :

Laser power meter reading : 7.0 ± 0.2 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

(Optical pick-up label)

Checking Procedure:

1. Connect an oscilloscope to CN110 pin 3 (TE) and CN110 pin

1 (VC) of the BD board.

2. Load a disc (any available on the market). (Refer to Note 1.)

3. Press the ML/TUNING + button continuously and move

the optical pick-up outside the pit.

4. Press the lm/TUNING – button or ML/TUNING +

button and display “EF MO CHECK”.

5. Press the ENTER/YES “R” button and display “EFB =

MO-

R”.

(Laser power READ power/Focus servo ON/tracking servo OFF/

spindle (S) servo ON)

6. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not press the lm/TUNING

– button or ML/TUNING + button.

(Read power traverse checking)

(Traverse Waveform)

7. Press the ENTER/YES “R” button and display “EFB =

MO-

W”.

8. Observe the waveform of the oscilloscope, and check that the

specified value is satisfied. Do not press the lm/TUNING

– button or ML/TUNING + button.

(Write power traverse checking)

(Traverse Waveform)

5. Press the MENU/NO “R” button and display “LDPWR

CHECK” and stop the laser emission.

(The MENU/NO “R” button is effective at all times to stop the

laser emission.)

Note 1: After step 4, each time the ENTER/YES “R” button is

pressed, the display will be switched between “LD 0.7 mW

$

”, “LD 6.2 mW $ ”, and “LD WP $ ”.

Nothing needs to be performed here.

5-6-3. Traverse Check

Connection :

Loading...

Loading...