TS 410, TS 420

English

12

Severed parts

With openings, recesses, etc., the

sequence of the cuts is important.

Always make the last cut so that the

abrasive wheel does not become

jammed and so that the operator is not

endangered by the severed or

separated part.

If necessary, leave small ridges that hold

the part that is to be separated in

position. Break these ridges later.

Before finally separating the part,

determine:

– how heavy the part is

– how it can move after separation

– whether it is under tension

When breaking out the part, do not

endanger assistants.

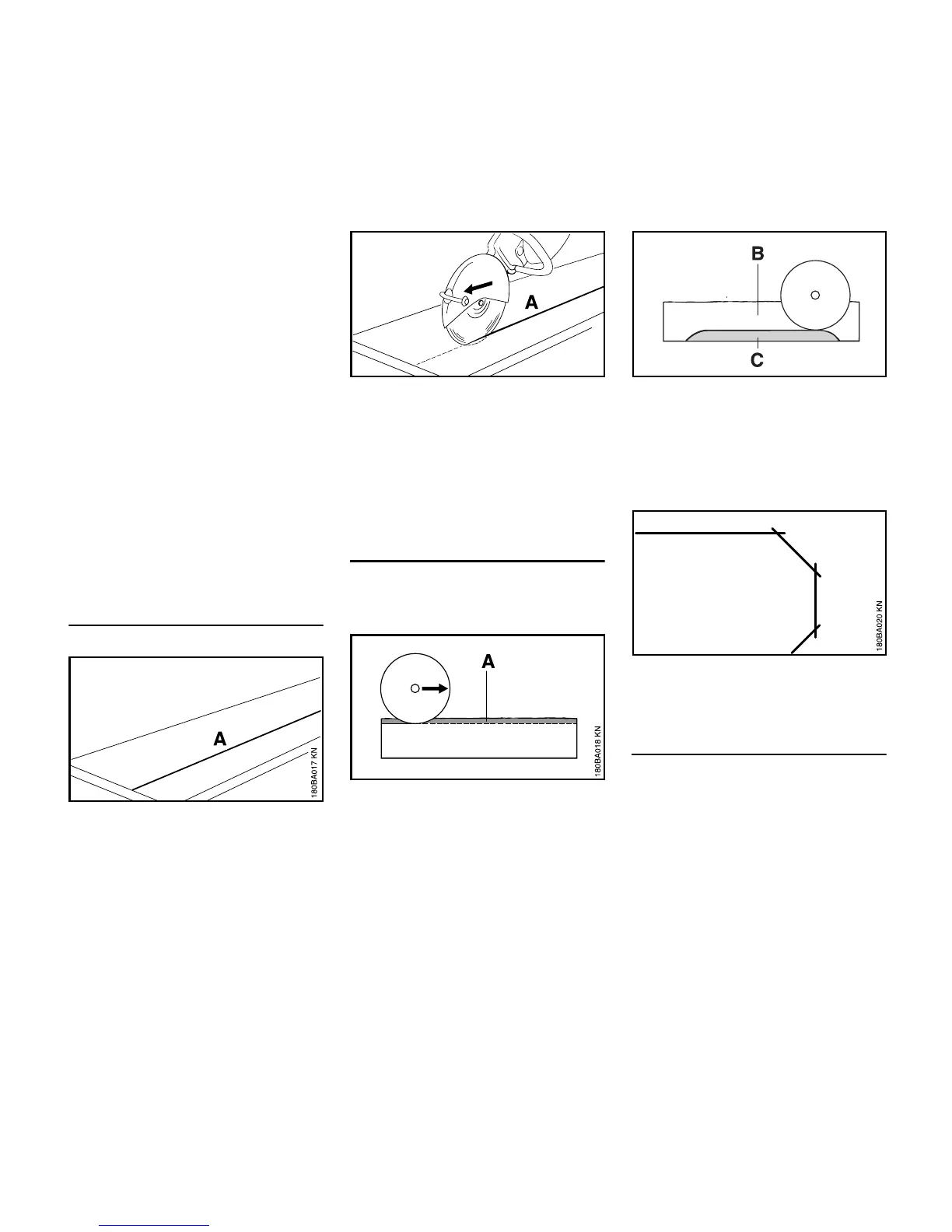

Cut in several passes

N Mark cutting line(A)

N Work along the cutting line. When

making corrections, do not tilt the

abrasive wheel, but always set the

abrasive wheel against the

workpiece anew – the cutting depth

for each operation should not

exceed 5 to 6cm. Cut thicker

material in multiple operations

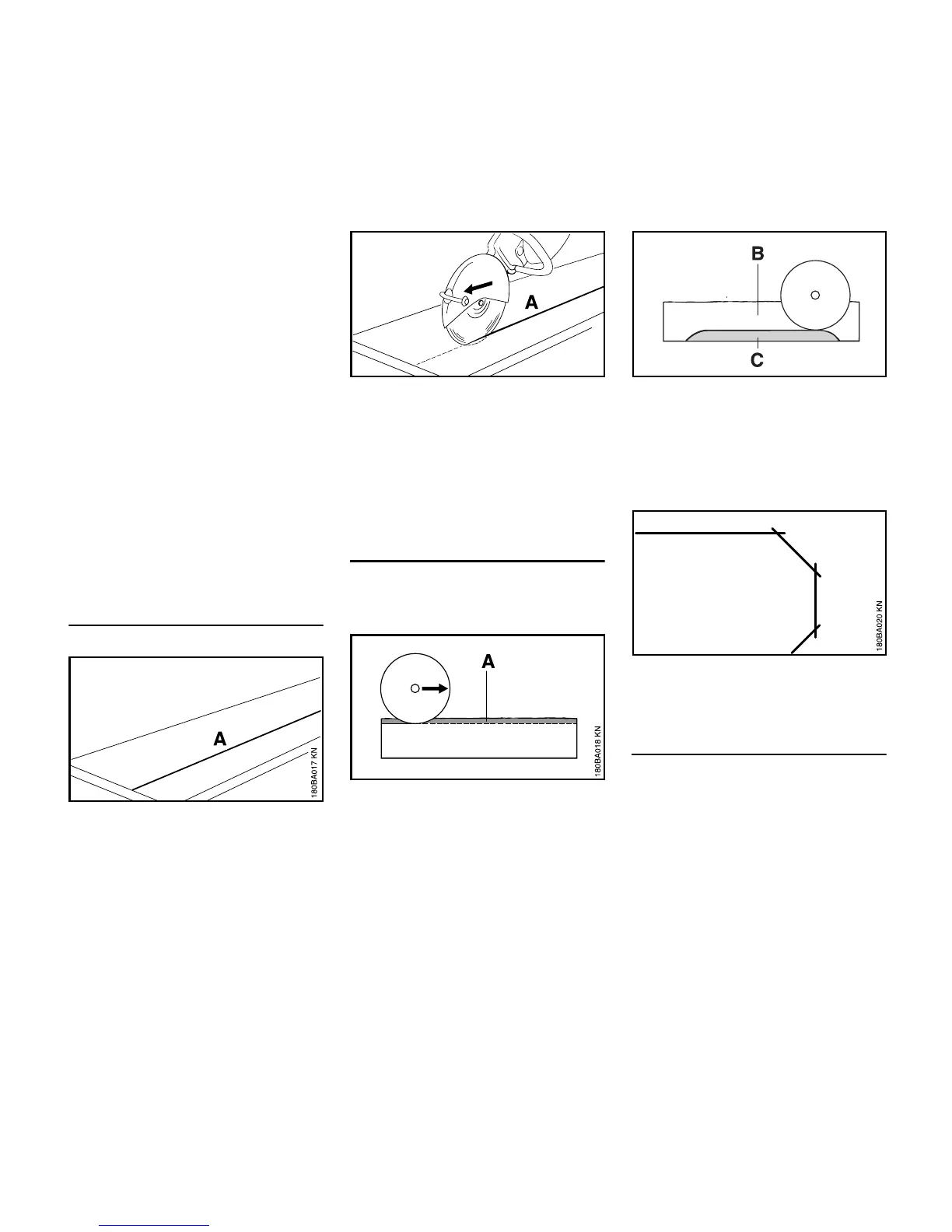

Cutting plates

N Secure the plate (e.g. on a non-slip

surface, sandbed)

N Grind a guide groove(A) along the

line marked

N Make the cut(B) deeper

N Leave a "hinge"(C)

N First sever the plate at the cut ends

so that no material breaks away

N Break plate

N Make curves in multiple operations

– make certain that the abrasive

wheel does not tilt

Cutting pipes, round and hollow bodies

N Secure pipes, round and hollow

bodies against vibrations, slipping

and rolling away

N Note direction of fall and weight of

the severed part

N Determine and mark the cutting line,

avoid reinforcement, especially in

the direction of the severing cut

N Determine sequence of severing

cuts

180BA027 AM

180BA028 AM

Loading...

Loading...