TS 410, TS 420

English

5

Cut-off machine, spindle bearing

Correct spindle bearings ensure the

concentricity and axial running of the

diamond-tipped abrasive wheel – if

necessary, get it checked by an

approved dealer.

Abrasive wheels

Selecting the abrasive wheels

Abrasive wheels must be approved for

hand-held cutting. Do not use other

cutting wheels and attachments – risk of

accident!

Abrasive wheels are suitable for

different materials: Observe the

identification of the abrasive wheels.

STIHL generally recommends wet

cutting.

Check the spindle hole for damage. Do

not use cutting wheels with a damaged

spindle hole – risk of accident!

Before fitting a used abrasive wheel,

check that it is not cracked, chipped,

undercut or uneven, and does not

display any signs of core fatigue or

overheating (discoloration); check also

that there are no damaged or missing

segments and that the spindle hole is

not damaged.

Never use cracked, chipped or bent

abrasive wheels.

Substandard and/or unapproved

diamond abrasive wheels can shimmy

during cutting. This shimmying can

cause such diamond abrasive wheels to

be abruptly braked or become stuck in

the cut – Danger of kickback! Kickback

can result in fatal injuries! Diamond

abrasive wheels that shimmy constantly

or even only intermittently must be

replaced immediately.

Never straighten diamond abrasive

wheels.

Do not use a cutting wheel which has

fallen to the ground – damaged cutting

wheels may break – risk of accident!

Observe the expiration date where resin

abrasive wheels are concerned.

Fitting abrasive wheels

Inspect the spindle of the cut-off

machine. Do not use a machine if the

spindle is damaged – risk of accident!

Note the arrows indicating the direction

of rotation on diamond abrasive wheels.

Position the front pressure plate –

tighten up the clamping screw – rotate

the cutting wheel by hand and take a

sight check for concentricity and axial

running.

Storing abrasive wheels

Store cutting wheels in a dry and frost-

free place, on an even surface, at

constant temperature – risk of breakage

and splintering!

Always protect the abrasive wheel

against sudden contact with the ground

or objects.

Before starting

Inspect the cut-off machine to check that

it is in full working order – observe the

respective chapters in the instruction

manual:

– Check the fuel system for leaks,

especially the visible parts, e.g.,

filler cap, hose connections, manual

fuel pump (only on machines with a

manual fuel pump). In case of

leakage and damage, do not start

the engine – risk of fire! Have the

machine serviced by a servicing

dealer before using it.

– The abrasive wheel must be

suitable for the material to be cut. It

must be in good condition and fitted

correctly (direction of rotation,

secure).

– Inspect the cutting wheel guard for

tight seat – if loose, contact your

specialist dealer.

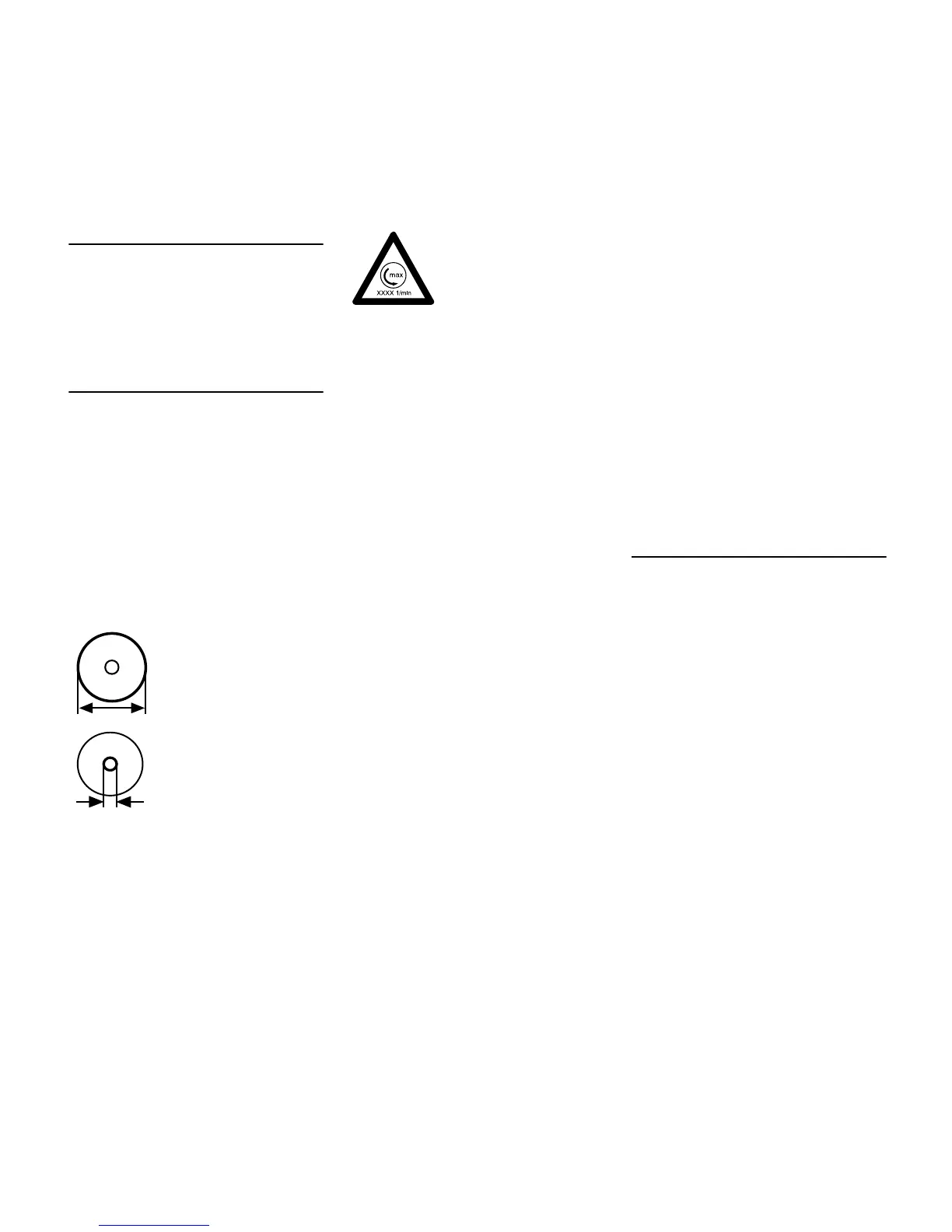

Observe the outer diame

-

ter of the abrasive wheel.

Spindle hole diameter of

the abrasive wheel and

shaft of cut-off machine

must match.

The permissible speed of

the abrasive wheel must

be equal to or greater

than the maximum spin

-

dle speed of the cut-off

machine. – Refer to the

chapter "Specifications".

Loading...

Loading...