1656 & 1657 Battery Element Tester Owner’s Manual

STS Instruments Page 23 of 88

4 Theory of Operation

This section provides background information on the test methodology used by the 1656/1657

Battery Element Tester.

4.1 Test Pulse Generation

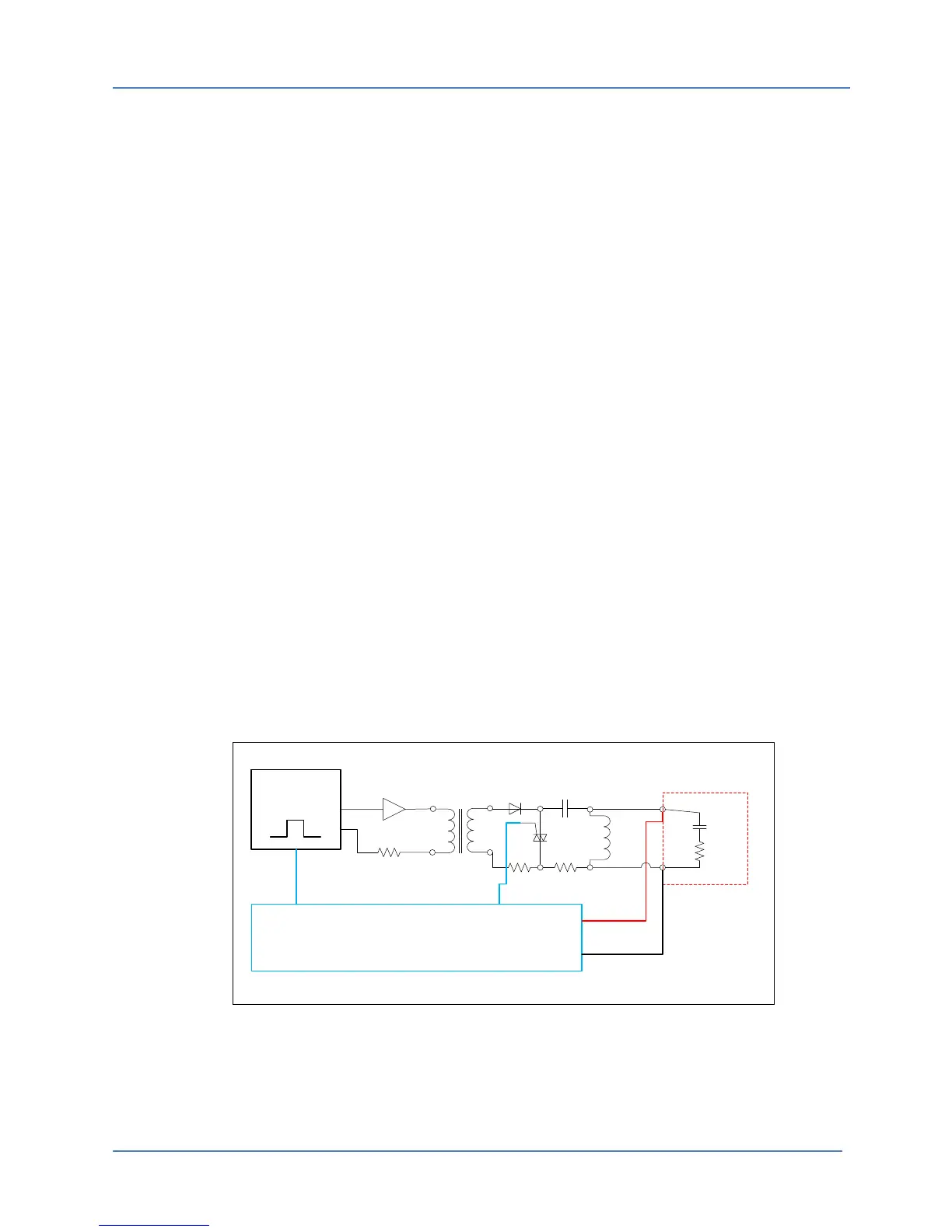

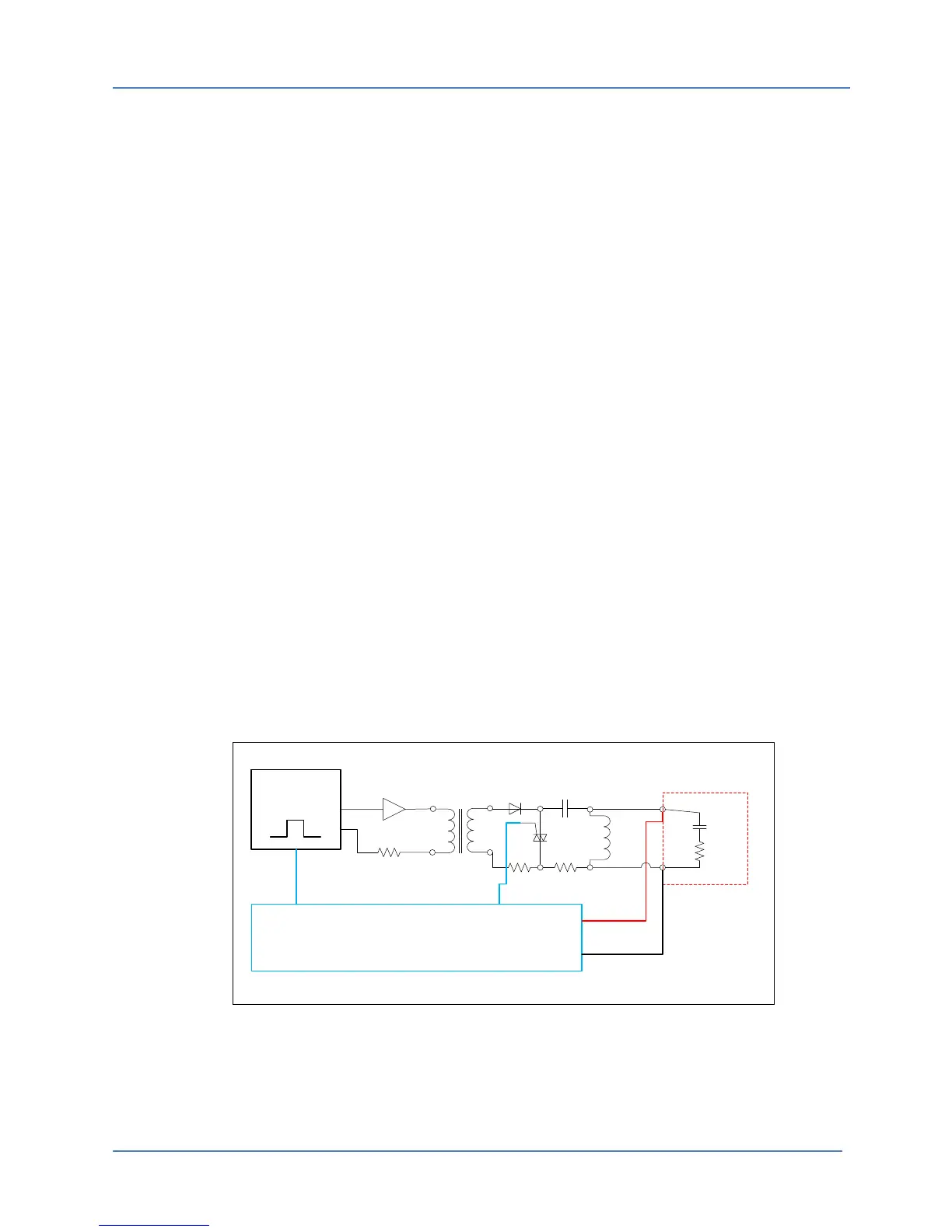

The 1656/1657 generates a short duration, high voltage spike at its output by quickly

discharging a charged capacitor that has been pre-charged. This capacitor is charged to the set

test voltage level using a half wave rectified DC supply operating from a high voltage step-up

transformer. The digital controller sets the primary voltage level of this transformer using a DAC

based on the user’s programmed set point. This provides an accurate and repeatable test

voltage waveform at the output of the 1656/1657test leads.

The discharge capacitors are charged on the negative half cycles of the AC line input. On the

alternate half cycles, a Silicon Controller Rectifier (SCR) is triggered by the digital controller so

that the capacitor is discharged into the load while the main charging circuit is in a non-

conducting condition. The digital measurement system uses precision Analog to Digital

converters (ADC’s) to digitize the resulting output voltage waveform. This data is processed by

the microcontroller (MCU) to verify the applied test voltage is correct.

An internal bleed load-switching coil is connected across the output terminals of the unit to

produce a fixed load condition while the unit is operating under standby (no load) conditions.

4.2 Back EMF Measurement

Under normal conditions, discharge of the capacitors into the internal coil creates a strong

magnetic field in the core of this inductor load. When the forward pulse dies off, this magnetic

field collapses producing a back Electro Magnetic Force (EMF) which is captured by the digital

controller’s measurement read back circuits. An average peak voltage read back value is

obtained over a number of successively applied test pulses.

Digital Pulse

Generator

MCU Digital Board

High Voltage

Transformer

Diode

SCR

Coupling Cap.

Trigger

R

R

Buffer

R

Internal

Coil

HV Terminals

R

C

Battery

Element

(UUT)

Measurement

Inputs

Figure 4-1: Equivalent Battery Element Tester Schematic

Any external load, such as a battery cell under test, is effectively in shunt with the internal bleed

load coil (as shown in Figure 4-1) and therefore, will reduce the back EMF signal, resulting in a

Loading...

Loading...