Motor Service

Motor

Advanced DC Motors

The enclosed Advanced DC motors must be

disassembled to inspect the motor brushes. Refer to

Motor Inspection for information regarding

disassembling the motor.

MOTOR REMOVAL AND

INSTALLATION

See the Transmission section for information on

removing or installing the motor.

MOTOR INSPECTION

Disassembly

1. Remove the motor from the vehicle. See the

Transmission section for information on

removing the motor.

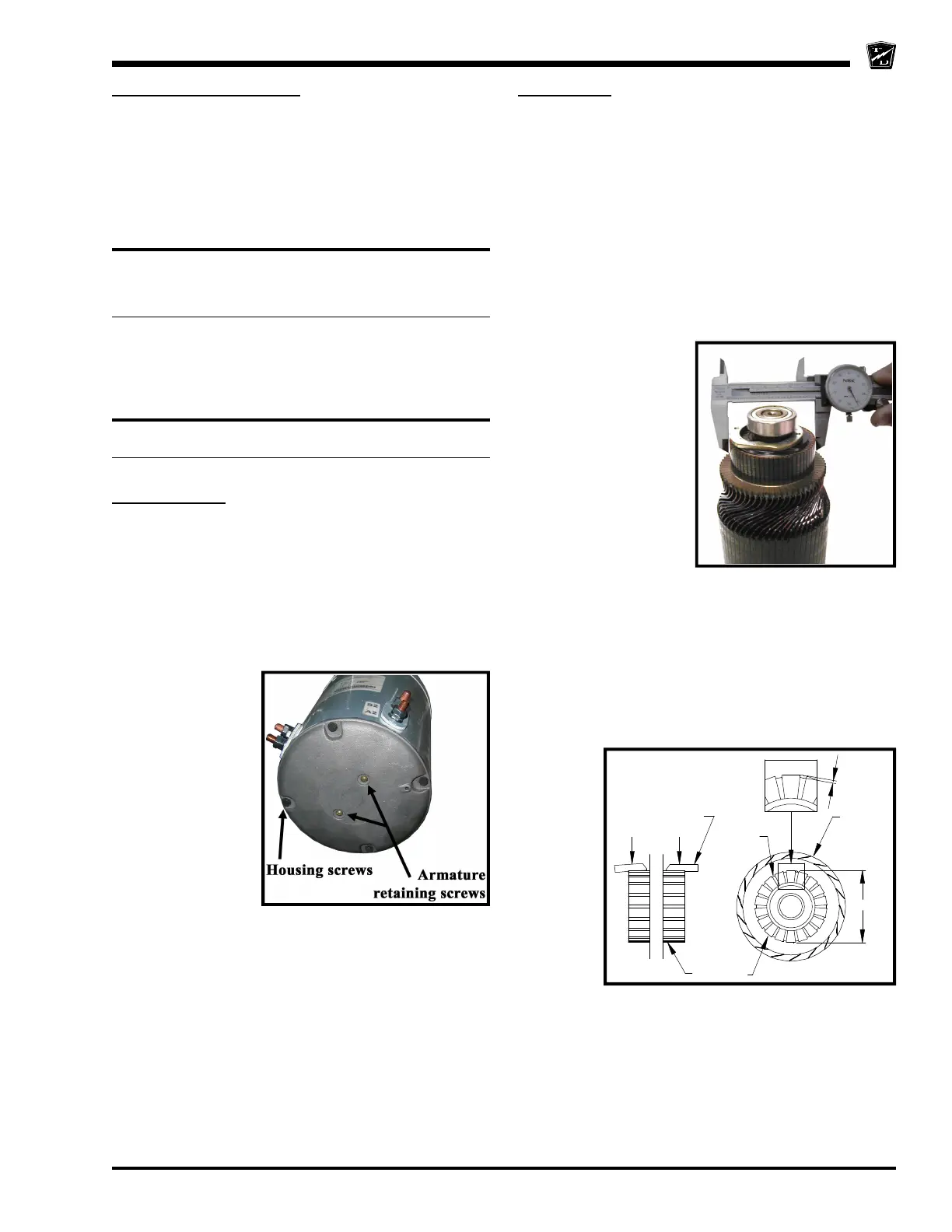

2. Remove the housing screws from the rear and/or

front of the motor.

3. Remove the armature retaining screws from the

rear housing (if equipped).

4. If this is an enclosed motor, remove the front

housing end.

5. Pull the armature out of the front end of the motor

housing.

6. Remove the nuts off of all of the terminals in the

rear motor housing.

7. Remove the rear motor housing being careful not

to damage the field coil wires.

Inspection

1. Measure the length of each motor brush.

• If any one brush is less than or equal to the

service limit specified in section Service

Limits, then all four brushes should be

replaced. Refer to Replacing the Brushes

section for information regarding replacing the

motor brushes.

2. Measure the diameter of the commutator.

• If the commutator is less than the minimum

diameter specified in section Service Limits,

then the motor must be replaced.

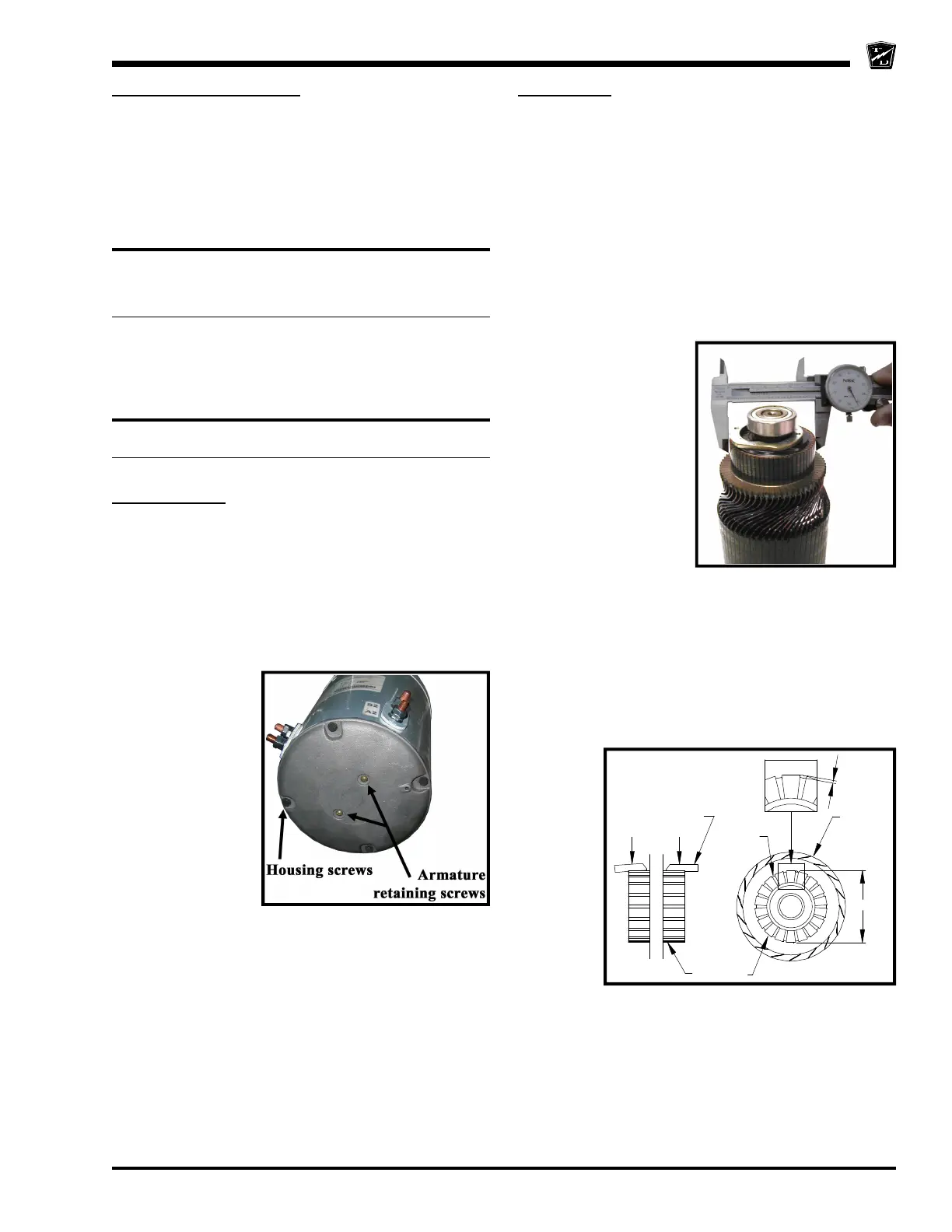

3. Measure the commutator undercut depth in 5-

places around the commutator.

• If any one of the measurements is less than the

minimum undercut depth specified in Service

Limits above, then the commutator must be

undercut. Refer to Repair Commutator

section for information regarding undercutting

the commutator.

4. Inspect the commutator for grooves.

• If the commutator is groved then it must be

machined on a lathe. Do not machine the

commutator past the minimum diameter

specified in Service Limits section. Refer to

Repair Commutator section for information

regarding machining the commutator.

Insulation

Commutator

Incorrect

Hacksaw blade

Correct

Min. OD

Armature

Undercut

Loading...

Loading...