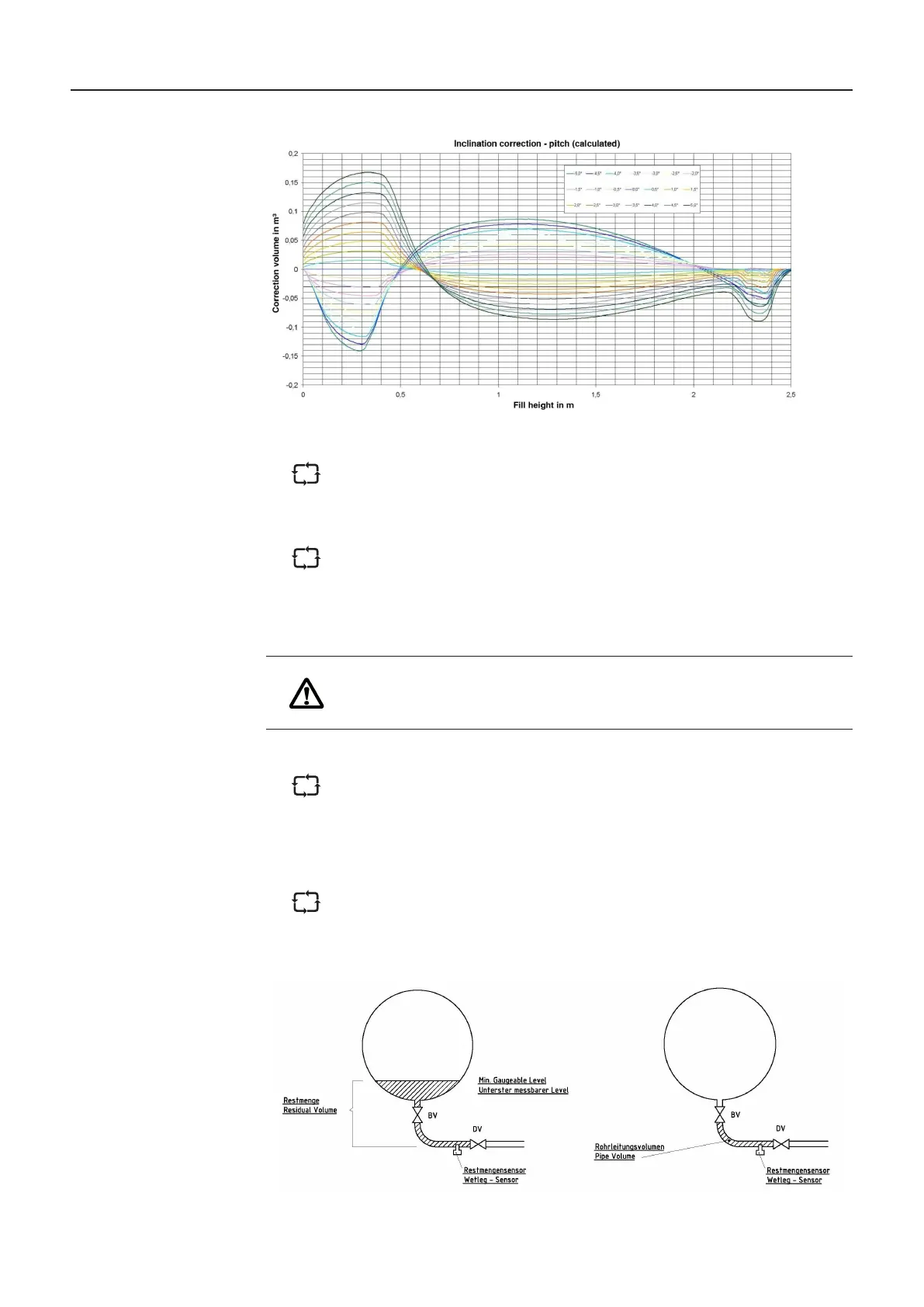

Figure 6: Typical inclination correction curves

The calibration limit of the absolute inclination correction values is determined

by the accuracy of the angle sensor. If the correction values become too large

in relation to the size of the compartment, the error due to the angle sensor

exceeds the calibration limits and the compartment can no longer be calibrated.

A deviation of the level sensor from the target position due to manufacturing

tolerances also produces a measuring error. Compensation is possible within

limits by means of the computational shifting (X/Y shift) of the level sensor to its

ideal position. However, in this case also there is an additional error due to the

ATTENTION:

Level sensor measuring compartments place stricter demands on the

manufacturing tolerances. The more precise manufacturing is, the simpler

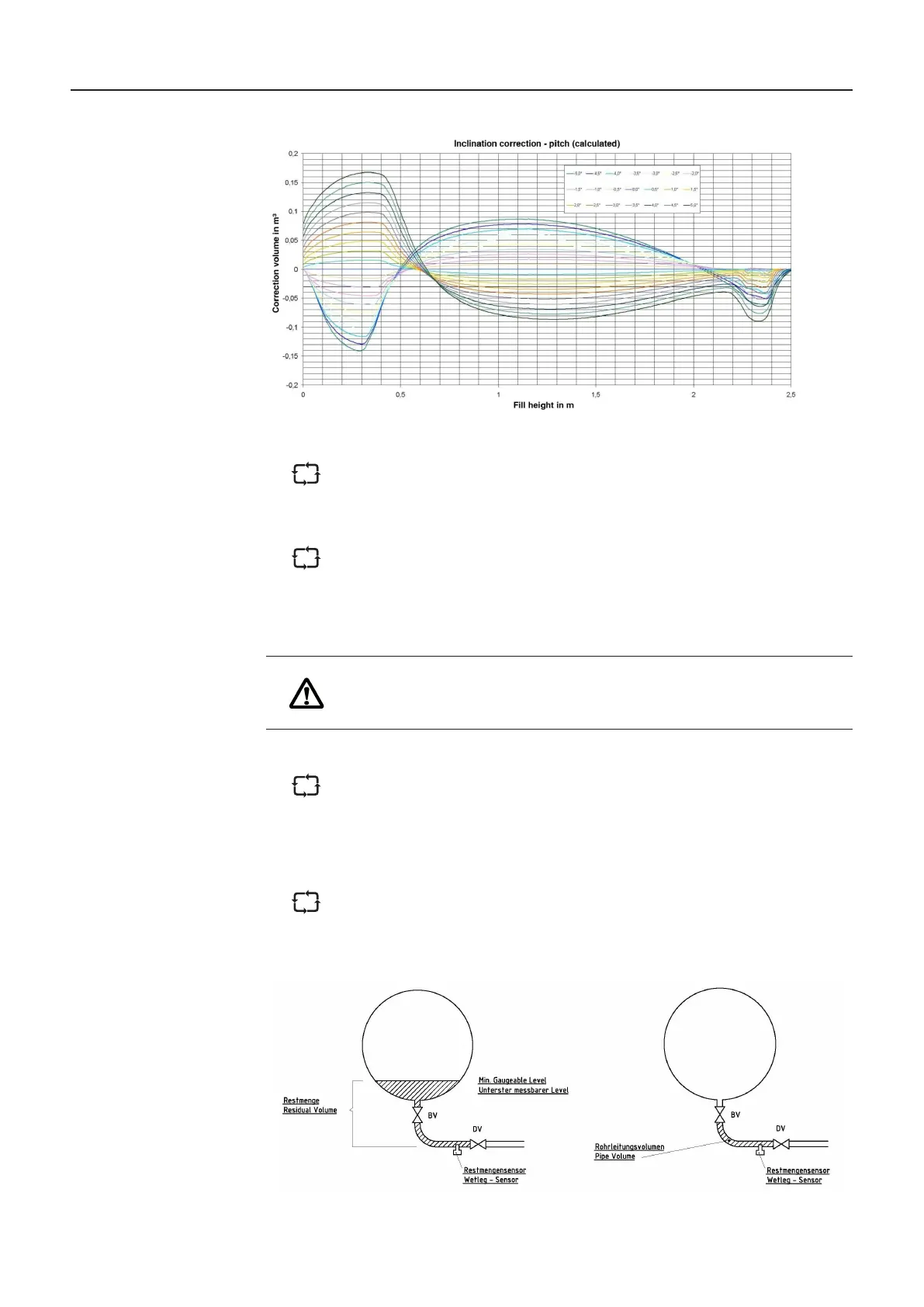

in the piping measured by the level sensor. Therefore, the residual quantities

way, once the tank compartment has been emptied to the extent that the

As soon as the level falls below the measurable range, no further quantity

is added to that already indicated. The residual volume is only added to the

delivery quantity when the wet leg sensor becomes dry at the end of the

in the following diagram.

Figure 7:

MultiLevel Instruction Manual Description of the Level Gauging System

Drawing 73-WM-008

Loading...

Loading...