p

Model 880 DEPOSITION CONTROLLER

y

SECTION 2.XX

e page 27 of 275 ^

<< crystals 2.2 >>

cal and theory (ch 4, 1

st

page) [keep ch 4-like intact, repetition ok, use see ch 4 to link].

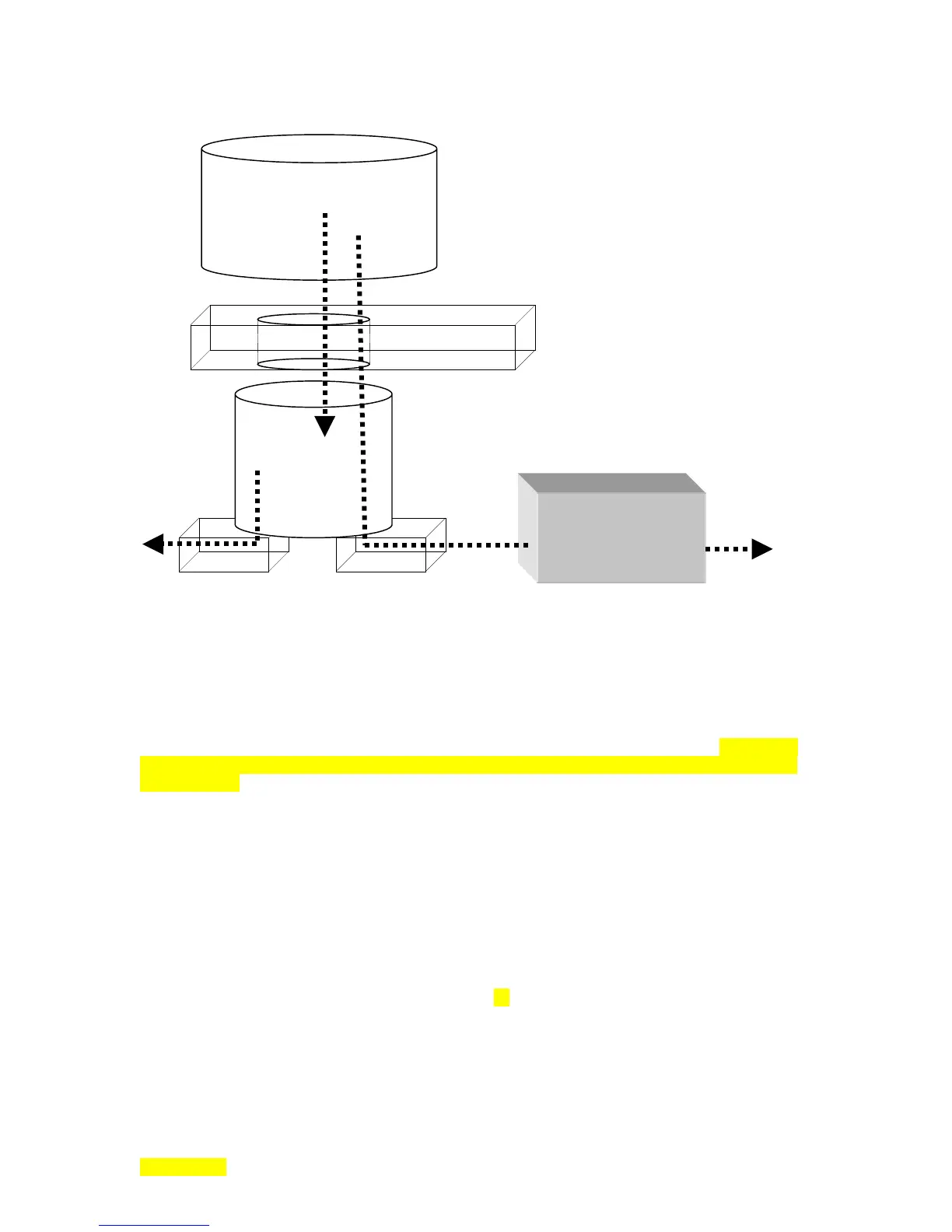

When the chamber is appropriately pumped down, the source material is heated/excited such that molecules

become the evaporant stream and are dispersed.

To reiterate, the source material is known as an evaporant when it has reached sufficient

temperature/excitation to leave the surface of the source material supply prior to deposition. A vacuum is

necessary to provide a decreased potential for atomic collisions and contamination (better dispersion with

less impurities). The Model 880 automatically, as it monitors material deposition rate and thickness,

controls the power that generates the evaporant within the bounds of the user-defined parameters and other

programming. The Model 880 is programmed through an LCD screen with a touch panel overlay. All

choices are deterministic or bounded by a screen-specified range with software enforcing the range of entry

acceptance. The Model 880 can also be programmed through the communication port.

The Model 880 monitors material deposition rate and thickness by means of the crystal sensor, which

occupies the same space as the substrate.

.<< control loop=2-12 >>.

As the deposition process is transpiring within a vacuum chamber, the resonant frequency of a quartz

crystal sensor, also exposed to the same evaporant as the substrate within the chamber, accumulates

deposited film[s] on its surface. The equation in section x7 describes the relationship between the mass of

such a film deposition and the measured frequency of the sensor crystal. Knowing the frequency change

due to accumulated mass, the film thickness can be determined. The rate of accumulated material

thickness can be calculated using the film thickness along with other elements and progression through

time. Contributing factors include crystal sensor placement, material characteristics, etc. The Model 880

numerically displays rate, thickness and power. It graphically displays rate, power or rate deviation.

Gate Valve

Purge Valve Rough Valve

Roughing Pump

Chamber

Cryopump

Loading...

Loading...