axle lockout valve should be checked daily as follows:

1. Place boom in travel position.

2. Drive one tire of the rear (oscillating) axle up on an eight

inch block.

3. Swing the retracted unloaded boom approximately 20

degrees from the center position.

4. Drive the crane off the block. If the tire remains in the

up position proceed with step (5). If the tire does not re-

main in the up position readjust or replace lockout valve.

5. Allow crane to set for three to five minutes.

6. Observe the tire, it should remain in the up position.

7. Swing the crane back to the center position, the tire

should return to its original position. If not readjust or

replace the lockout valve and repeat this procedure.

SERVICE & ADJUSTMENTS

6 - 12

AXLE LOCKOUT SYSTEM

Air in the axle lock circuit decreases sta-

bility. Bleed the system immediately

whenever this occurs.

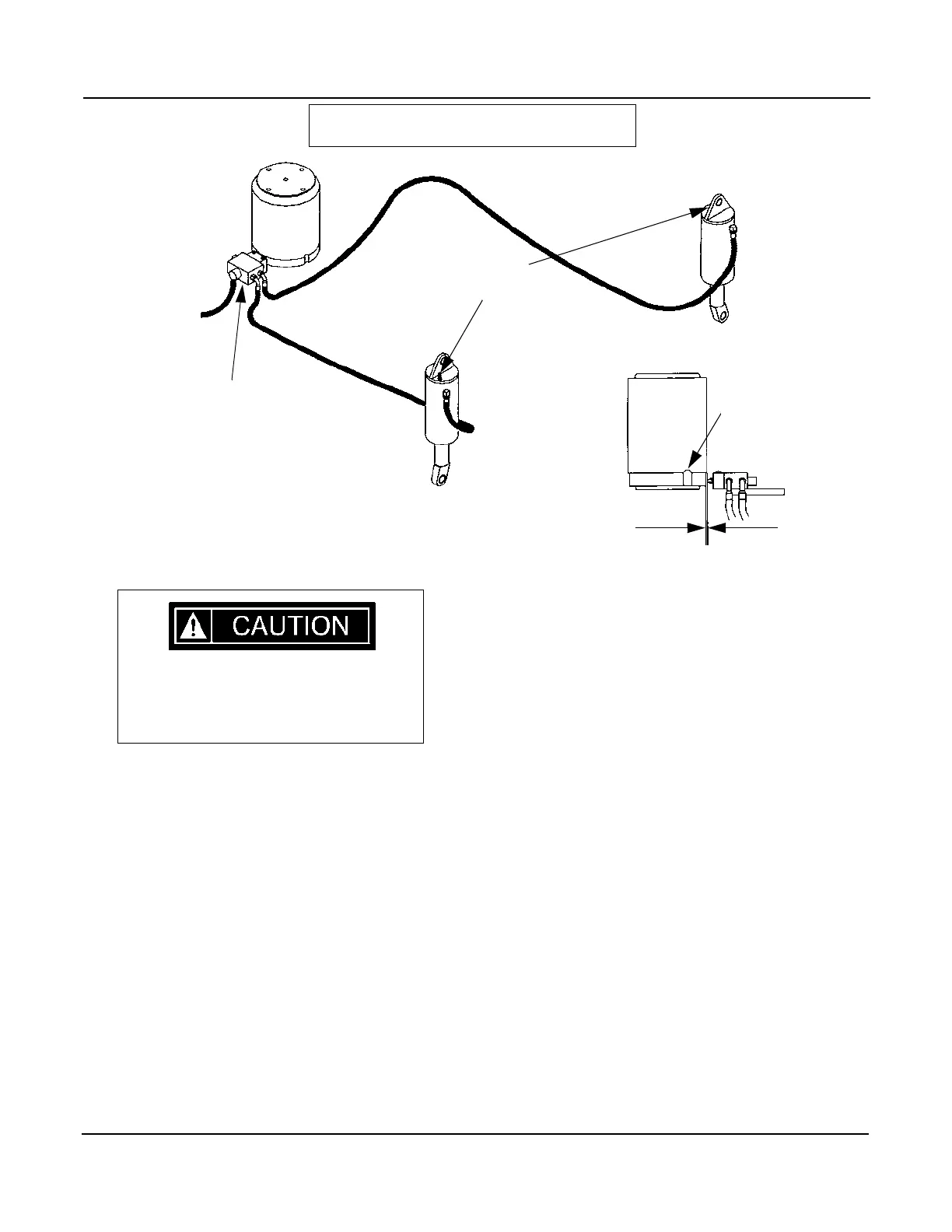

If the axle does not hold in the blocked position or oscillates

when the upper structure is swung 20 degrees from the travel

position, bleed the system.

Swing the retracted unloaded boom into the travel position so

that the lock valve will open. With the engine running at an

idle, loosen the bleeder screw. When a steady flow of oil is

running from the bleed screw, retighten the bleeder screw.

ADJUSTMENT

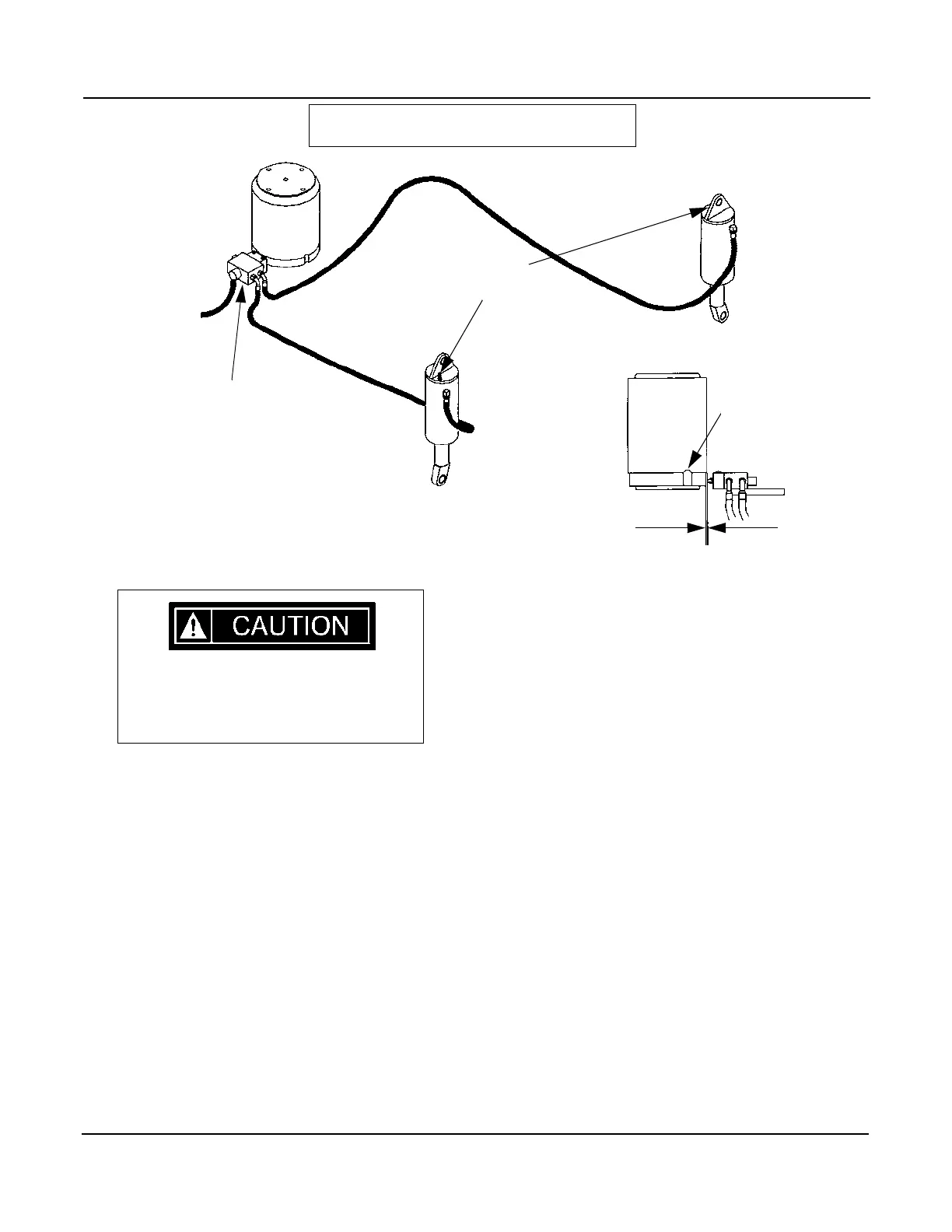

With the cam plunger fully retracted, adjust valve position for

.005-.010 inches gap between the cam roller and the cam trav-

el area on the manifold. Do not measure at the low point on

the manifold.

Tighten and secure with nuts, washers, and capscrews.

OPERATION CHECK

For safe operation of the crane when operating on rubber, the

AXLE LOCKOUT SYSTEM

LOW POINT ON

MANIFOLD

.005 / .010

AXLE LOCKOUT

VALVE

BLEED

SCREWS

Issued: August 2003RT700 Series

Loading...

Loading...