CABLE REEVING When reeving the machine for any

job, remember that hoisting and lowering speeds de-

crease as the number of parts of line increases. For the

most efficient use of the machine, it is desirable to use

the minimum number of required parts for lifting the an-

ticipated loads.

Never use less than the number of parts called for by

the load rating chart. The minimum required - number

of parts is determined by referring to the load rating

chart.

Care must be exercised when installing wire rope on

the winch drum. Improper spooling can. result in rope

damage through crushing, kinking, dog- legs, abrasion

and cutting. Poorly installed wire rope will also ad-

versely affect the operating characteristics of the ma-

chine by causing uneven application of force and

motion. This, in turn, can cause premature fatiguing

and failure of the rope.

Thoroughly inspect and clean the winch before pro-

ceeding with the installation. Check the lagging and

drum flanges for cracks, breaks and excessive wear.

Deformed or outsized drum and excessive undercut-

ting at the base of the flange also indicate that repair or

replacement of the drum is necessary.

Check the bearings for excessive wear and play.

After correcting any defects revealed by the inspection

and determining that the winch is in good operating

condition, spool the wire rope as follows:

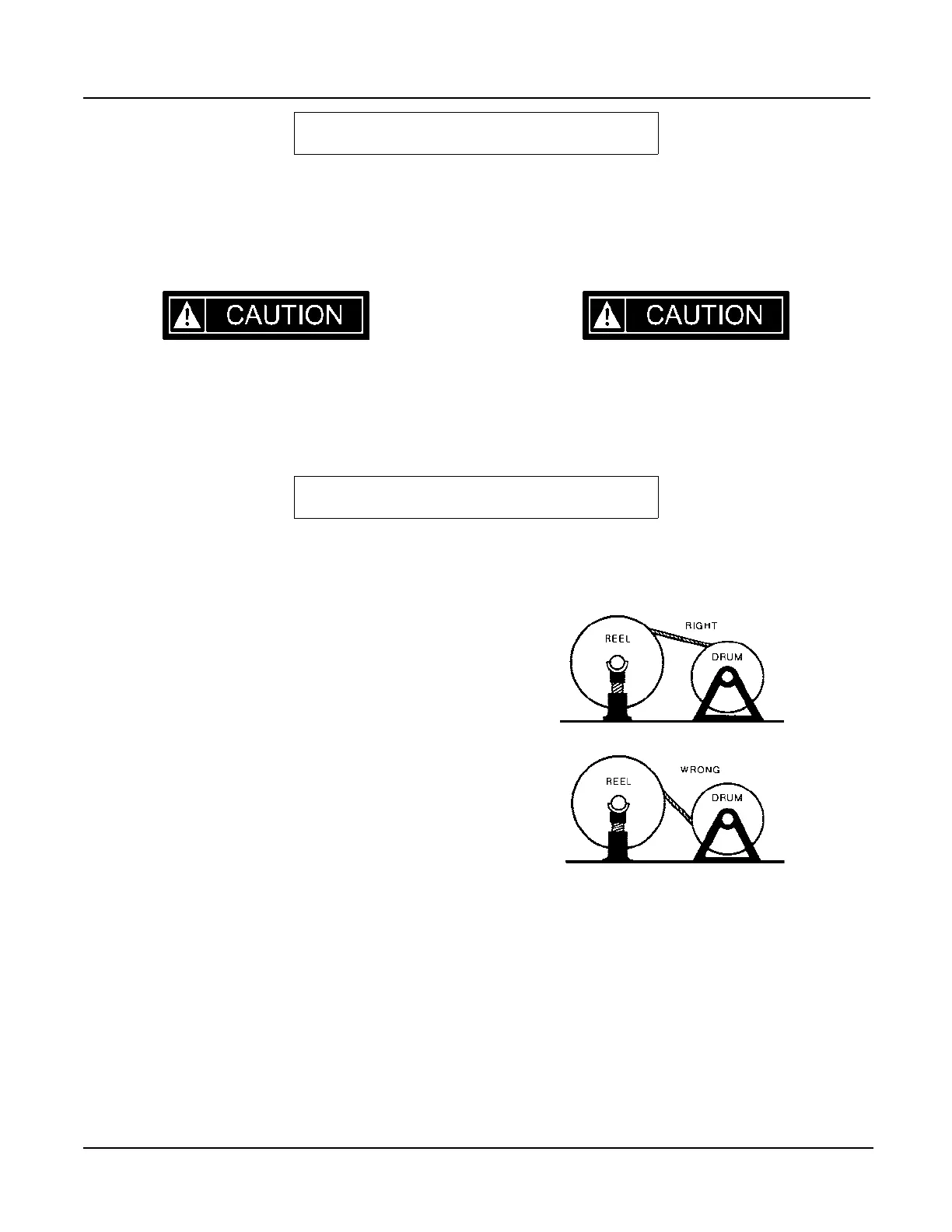

Mount the cable shipping reel vertically on jacks or a

suitable supporting structure, with a pipe or bar

through the reel center. The cable should be drawn

from the top of the reel, as shown, in order to avoid re-

verse bending as it is spooled onto the

If cable is wound from the storage reel onto the drum,

the reel should be rotated in the same direction as the

hoist.

Apply braking force to the reel flange in order to pre-

vent overrun as the rope is being drawn off. Loops

formed by overrun can cause kinks and doglegs in the

rope, resulting in damage and premature rope failure.

A timber or block forced against the shipping reel

flange can be used to provide the required braking

force.

MAINTENANCE AND LUBRICATION

CABLE REEVING

This machine incorporates a “Quick Reeving” boom

head and block which do not require removal of the

wedge and socket from the rope in order to change

the reeving. Removal of two pins in the boom head

and three in the hook block will allow the wedge and

socket to pass through.

NOTE: If a socket is changed or replaced, or if you are

changing hook block weights, it is IMPORTANT to

use the correct socket.

SPOOLING WIRE ROPE ON DRUMS

4 - 31 Revised: March 2005RT700 Series

Loading...

Loading...