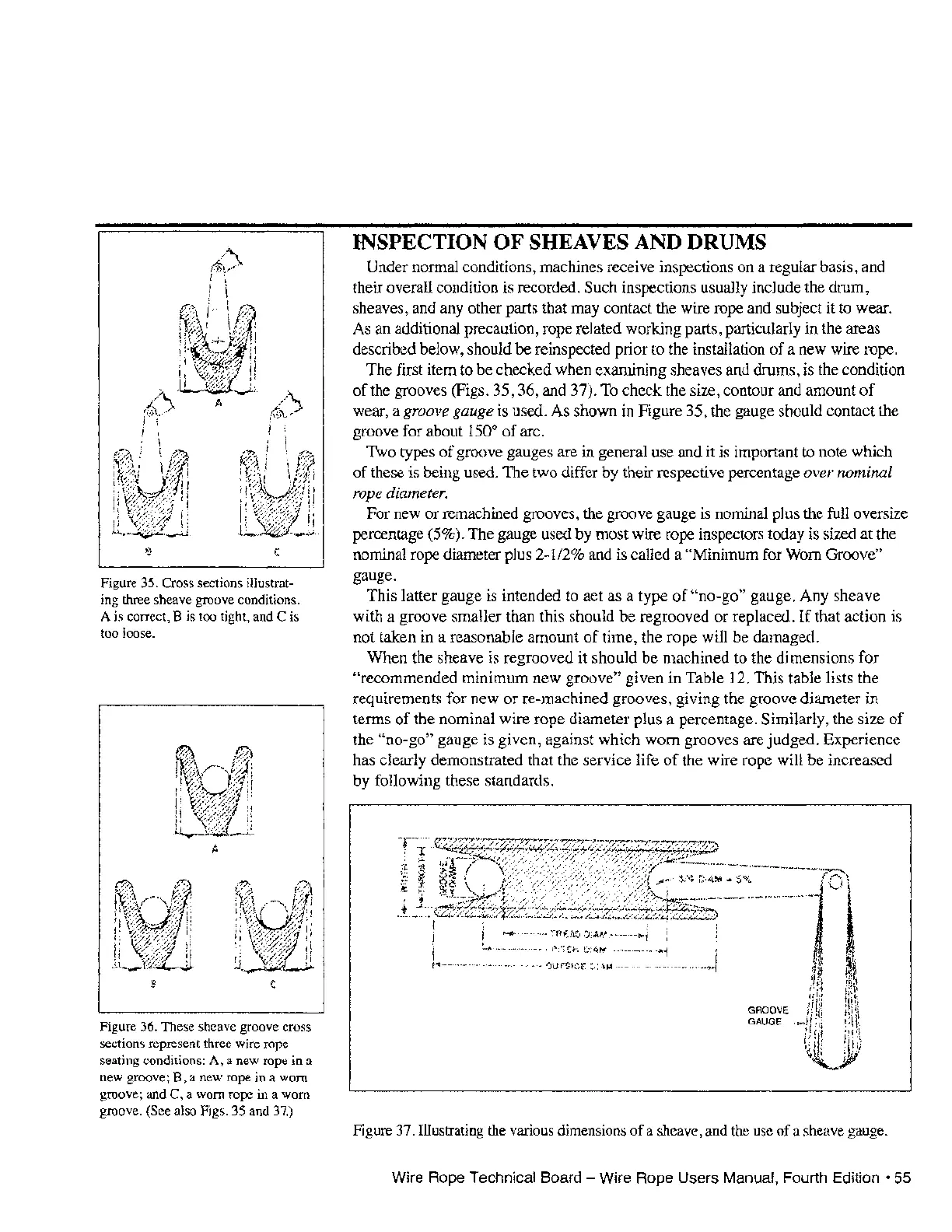

Figure 35. Cross sections illustrat-

ing three sheave groove conditions.

A is correct, B is too tight, and C is

too loose.

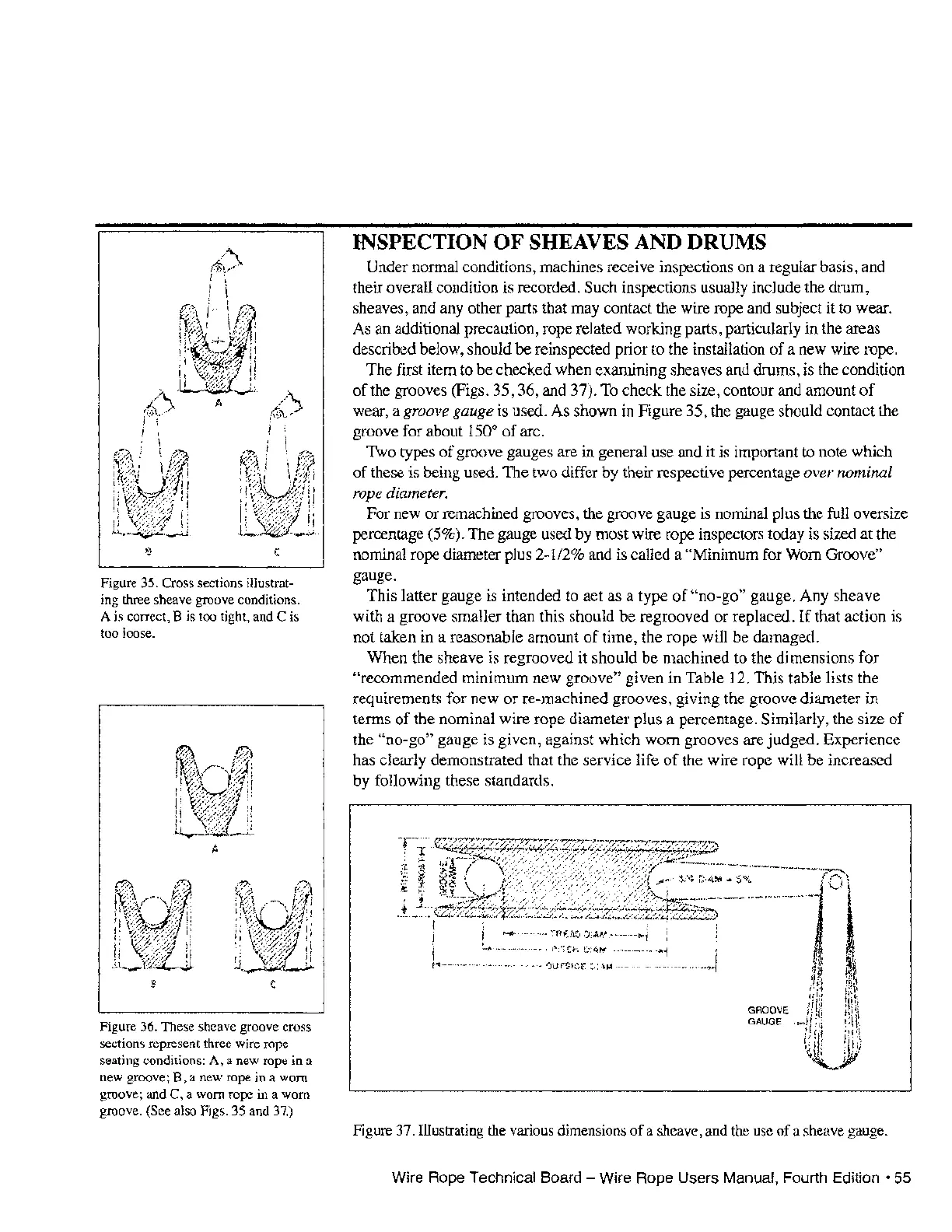

Figure 36. These sheave groove cross

sections represent three wire rope

seating conditions: A, a new rope in a

new groove; B, a new rope in a worn

groove; and C, a worn rope

in a worn

groove. (See also Figs. 35 and

37.)

INSPECTION OF SHEAVES AND DRUMS

Under normal conditions, machines receive inspections on a regular basis, and

their overall condition is recorded.

Such inspections usually include the drum,

sheaves, and any other parts that may contact the wire rope and subject it to wear.

As an additional precaution, rope related working parts, particularly in the areas

described below, should be reinspected prior to the installation

of

a new wire rope.

The first item to be checked when examining sheaves and drums, is the condition

of

the grooves (Figs. 35, 36, and 37). To check the size, contour and amount

of

wear, a

groove

gauge

is used. As shown in Figure 35, the gauge should contact the

groove for about

150

0

of

arc.

Two types

of

groove gauges are in general use and it is important to note which

of

these is being used. The two differ by their respective percentage over nominal

rope

diameter.

For new or remachined grooves, the groove gauge is nominal plus the full oversize

percentage (5%). The gauge used by most wire rope inspectors today is sized at the

nominal rope diameter plus 2-1/2% and is called a

"Minimum for Worn Groove"

gauge.

This latter gauge is intended to act as a type

of

"no-go" gauge. Any sheave

with a groove smaller than this should

be

regrooved

or

replaced.

If

that action is

not taken in a reasonable amount

of

time, the rope will be damaged.

When the sheave is regrooved it should be machined to the dimensions for

"recommended minimum new groove" given in Table 12. This table lists the

requirements for new

or

re-machined grooves, giving the groove diameter in

terms

of

the nominal wire rope diameter plus a percentage. Similarly, the size

of

the "no-go" gauge is given, against which worn grooves are judged. Experience

has clearly demonstrated that the service life

of

the wire rope will be increased

by

following these standards.

GROOVE

GAUGE

Figure 37. Illustrating

the

various dimensions of a sheave, and the

use

of a sheave gauge.

Wire Rope Technical Board - Wire Rope Users Manual, Fourth

Edition·

55

Loading...

Loading...