MAINTENANCE AND LUBRICATION

CABLE LUBRICATION METHODS

GENERAL We are covering the more commonly used

methods of lubricating cable (wire rope). For special

cable lubrication problems consult the cable manufac-

turer.

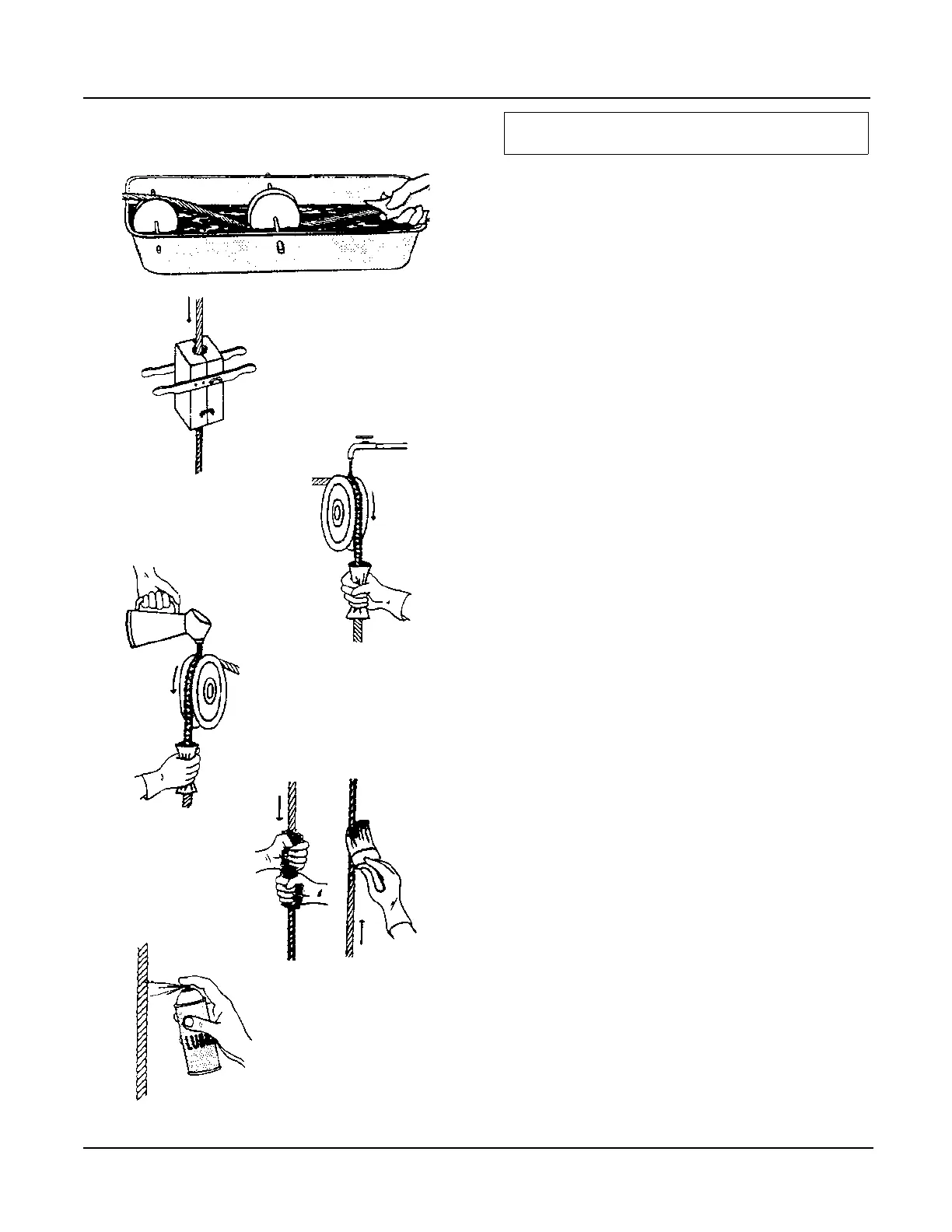

HOT APPLICATION A heated bath is placed in the

path of the wire rope, and the rope is passed through

the hot lubrication over sheaves and a center guide

wheel. Hot oils or greases have excellent penetrating

qualities and upon cooling have high adhesive and film

strength around each wire.

CONTINUOUS BATH Run an operating rope through

a specially constructed casing that has been packed

with swabbing and loaded with lubricant. This affords

continuous lubrication.

DRIPPING A container can be placed above the

sheave, so that the rope can be lubricated by opening

a spigot. Sheaves are the best location for lubricating

operating wire ropes, because the wires and strands

open somewhat as they bend along the groove.

POURING Lubricant can be poured on. The rope

should be lightly loaded and run slowly while being lu-

bricated.

SWABBING AND PAINTING Lubricant can be

swabbed on with rags, or painted on with a brush. Both

are quick methods which can be made part of the op-

erating routine.

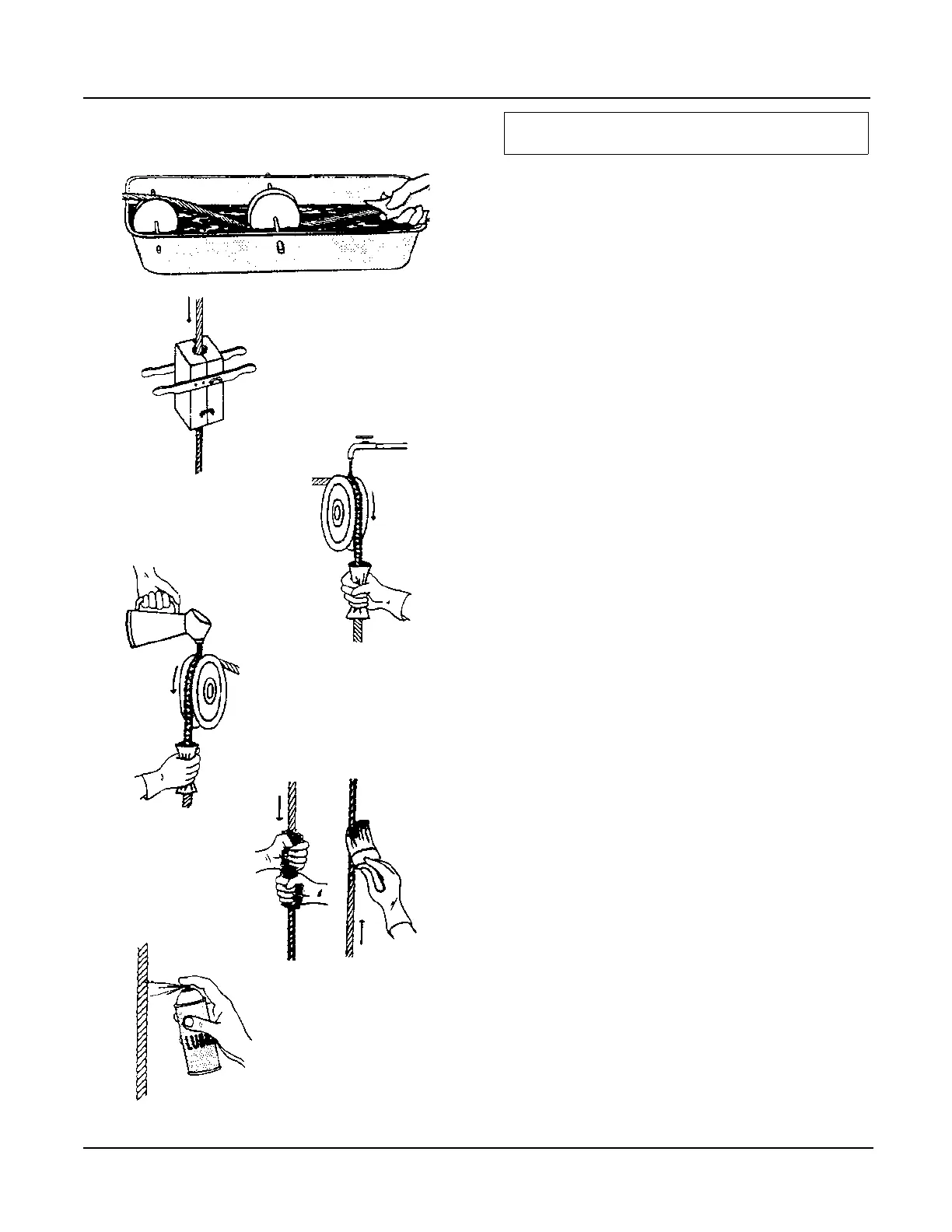

SPRAYING A light lubricant containing solvents can

be applied to a wire rope by a properly directed spray

nozzle.

AEROSOL SPRAYING Installations requiring only

small amounts of lubricants, or only occasional appli-

cations, may find the new aerosol cans of lubricant

useful. They are available from several lubricant man-

ufacturers.

Hot Application

Continuous Bath

Dripping

Pouring

Swabbing

And Painting

Aerosol Spraying

4 - 26 Revised: March 2005RT700 Series

Loading...

Loading...