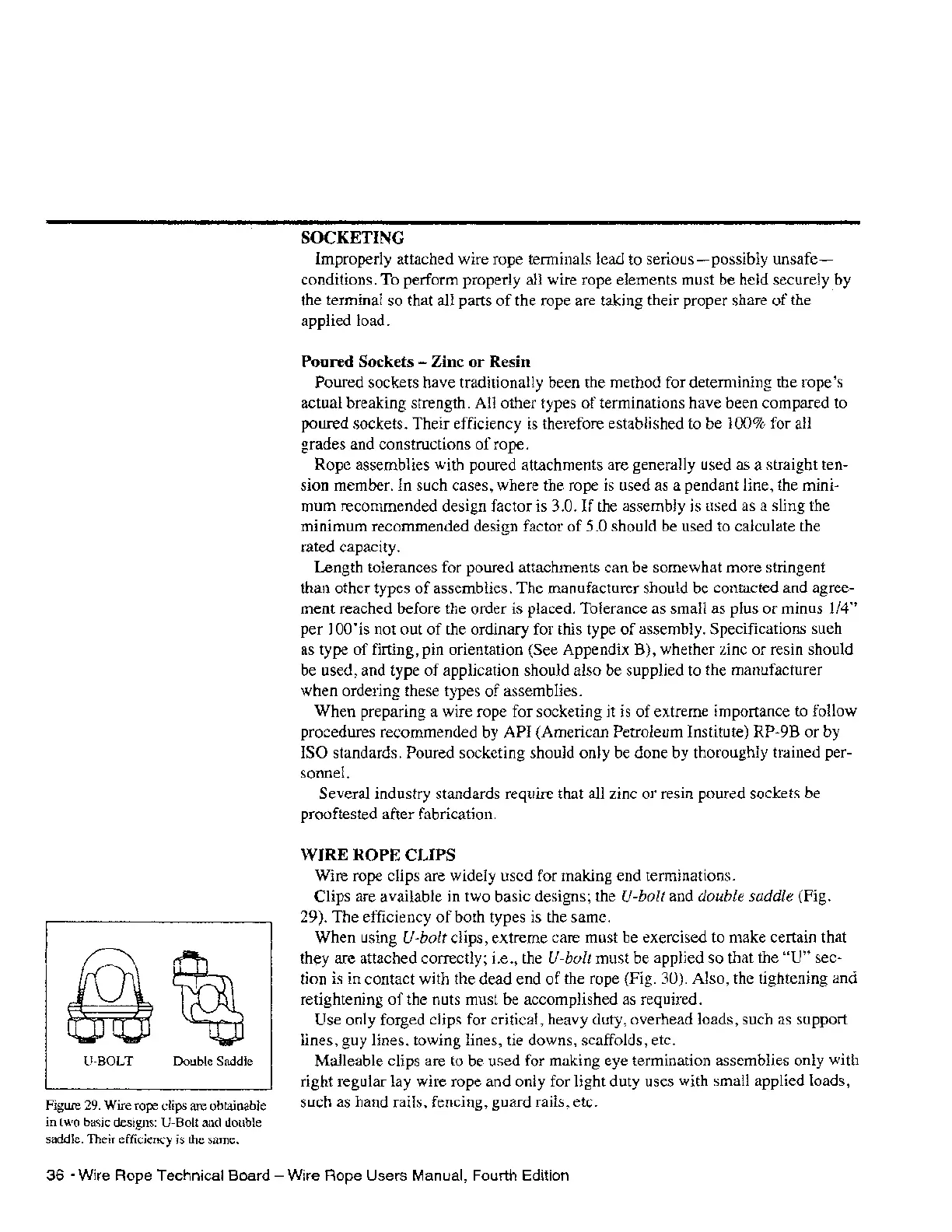

U-BOLT

Double Saddle

Figure

29.

Wire rope clips

are

obtainable

in

two

basic

designs: U-Bolt

and

double

saddle. Their efficiency

is

the

same.

SOCKETING

Improperly attached wire rope terminals lead to

serious-possibly

unsafe-

conditions.

To

perform properly all wire rope elements must be held securely.by

the terminal so that all parts

of

the rope are taking their proper share

of

the

applied load.

Poured Sockets - Zinc or Resin

Poured sockets have traditionally been the method for determining the rope's

actual breaking strength. All other types

of

terminations have been compared to

poured sockets. Their efficiency is therefore established to be

100% for all

grades and constructions

of

rope.

Rope assemblies with poured attachments are generally used as a straight ten-

sion member. In such cases, where the rope is used as a pendant line, the mini-

mum recommended design factor is 3.0.

If

the assembly is used as a sling the

minimum recommended design factor

of

5.0 should be used to calculate the

rated capacity.

Length tolerances for poured attachments can be somewhat more stringent

than other types

of

assemblies. The manufacturer should be contacted and agree-

ment reached before the order is placed. Tolerance as small as plus or minus

1/4"

per 100'is not out

of

the ordinary for this type

of

assembly. Specifications such

as type

of

fitting, pin orientation (See Appendix B), whether zinc or resin should

be used, and type

of

application should also be supplied to the manufacturer

when ordering these types of assemblies.

When preparing a wire rope for socketing it is

of

extreme importance to follow

procedures recommended by API (American

Petroleum Institute) RP-9B or by

ISO standards. Poured socketing should only be done by thoroughly trained per-

sonnel.

Several industry standards require that all zinc or resin poured sockets be

proof tested after fabrication.

WIRE

ROPE CLIPS

Wire rope clips are widely used for making end terminations.

Clips are available in two basic designs; the

U-bolt and double saddle (Fig.

29). The efficiency

of

both types is the same.

When using

U-bolt clips, extreme care must be exercised to make certain that

they are attached correctly; i.e., the

U-bolt must be applied so that the

"U"

sec-

tion is in contact with the dead end

of

the rope (Fig. 30). Also, the tightening and

retightening

of

the nuts must

be

accomplished as required.

Use only forged clips for critical, heavy duty, overhead loads, such as support

lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable clips are to be used for making eye termination assemblies only with

right regular lay wire rope and only for light duty uses with small applied loads,

such as hand rails. fencing, guard rails, etc.

36'

Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...