Engine productivity, longevity, and low-cost perfor-

mance depend on a regular program of periodic main-

tenance. The materials presented here are listed in

accordance with the MAINTENANCE CHECK LIST in

Section 4. Consideration may dictate a revision in

scheduling for the periodic checks.

As a part of each periodic check, refer to the engine

manufacturer’s manual for engine maintenance re-

quirements. When servicing the engine, the engine

manufacturer’s recommendations take precedence

over those in this manual, should any discrepancy be

noted.

DAILY:

FUEL LEVEL The fuel tank is located on the left side

of the machine. Keep the tank as full as possible to

minimize condensation in cold weather.

Use a good grade of No. 2 diesel fuel. The tank capac-

ity is 80 gallons.

ENGINE OIL LEVEL The engine oil level is checked

with the dipstick located on the left side of the engine

(right side of machine). DO not check the oil level while

the engine is running nor immediately after stopping

the engine. For an accurate reading, allow 15 minutes

for the oil to drain into the sump before checking. Keep

the oil level as close to the full mark as possible. DO

NOT OVERFILL

Never operate the machine when the oil is above the

full mark or below the low mark.

WATER SEPARATOR

A water separator is used to remove water contamina-

tion from the fuel before it enters the engine. Water

contamination should be drained daily or before it be-

comes 1/2 full.

AIR CLEANER Inspect the air cleaner and it’s connec-

tions for leaks, dents and damage.

A vacuum actuated indicator mounted on the air clean-

er assembly indicates conditions of restricted flow

through the air cleaner. With the engine running at

maximum governed rpm, observe the yellow band on

the indicator piston. If the yellow band reaches the red

band on the plastic cylinder, service is necessary. At

this time, change the air cleaner filter element and

clean the intake screen.

When using a degreasing agent to clean the engine,

be sure to cover the vacuum actuated indicator (filter

minder) with a protective material. Engine degreasing

solvents have a polycarbonate base and can damage

or destroy the indicator.

MAINTENANCE AND LUBRICATION

ENGINE MAINTENANCE

For Cummins engine maintenance refer to Cummins Operation and Maintenance Manual

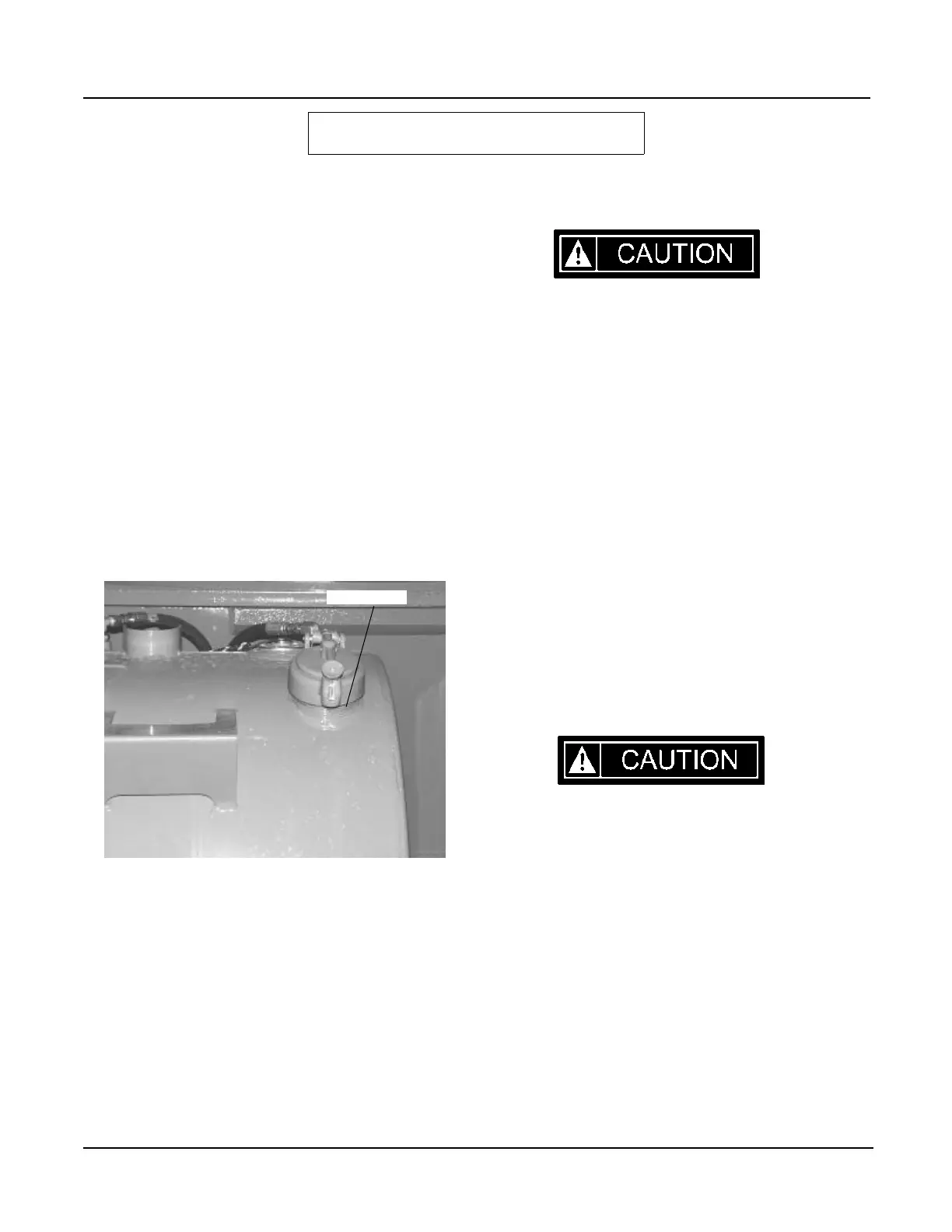

FILLER PIPE

4 - 7 Revised: March 2005RT700 Series

Loading...

Loading...