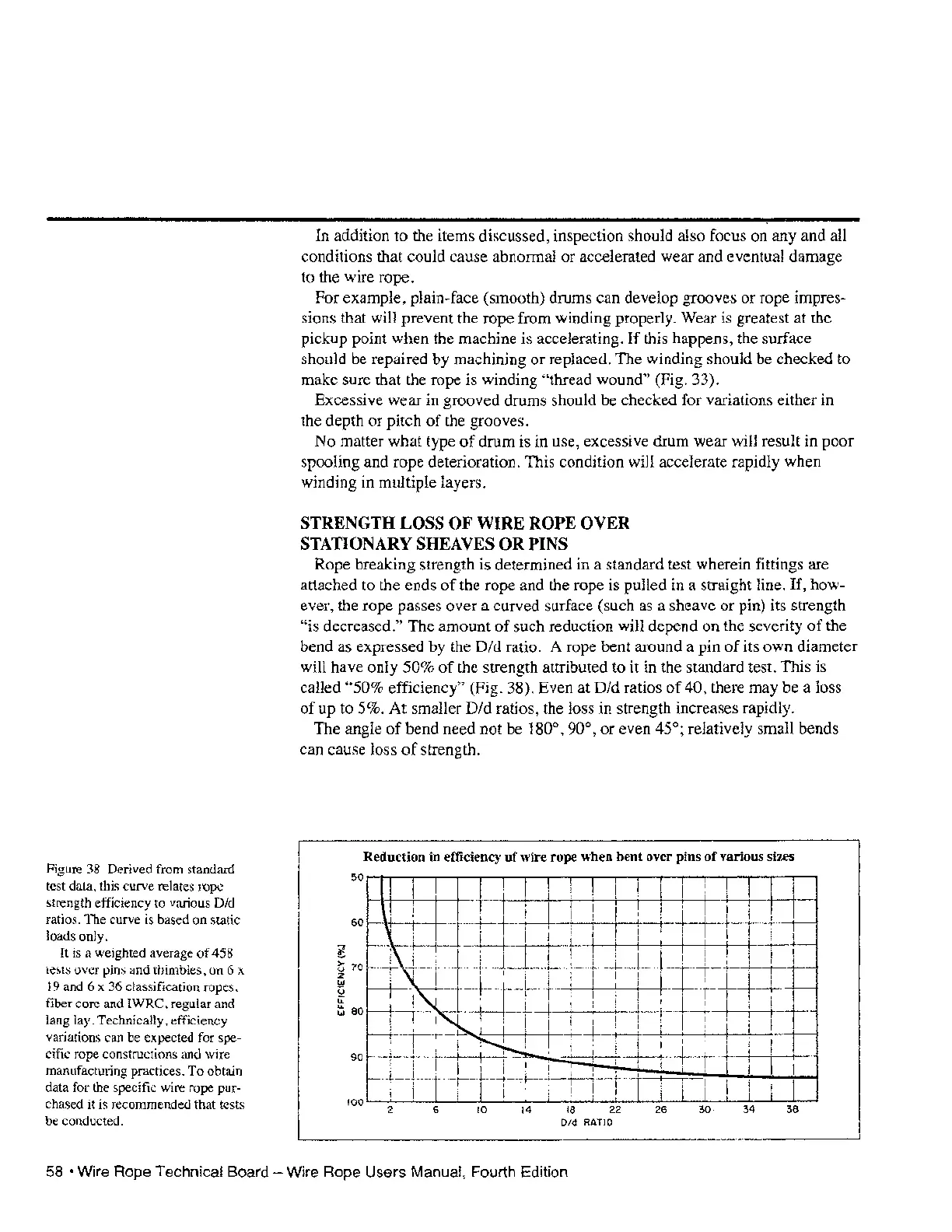

Figure 38 Derived from standard

test data, this curve relates rope

strength efficiency to various

Did

ratios. The curve is based on static

loads only.

It is a weighted average

of

458

tests over pins

and thimbles, on 6 x

19 and 6 x 36 classification ropes,

fiber core and IWRC, regular and

lang lay. Technically, efficiency

variations can

be

expected for spe-

cific rope constructions and wire

manufactUling practices. To obtain

data for the specific wire rope

pur-

chased

it

is

recommended that tests

be conducted.

In addition to the items discussed, inspection should also focus on any and all

conditions that could cause abnormal or accelerated wear and eventual damage

to the wire rope.

For example, plain-face (smooth) drums can develop grooves or rope impres-

sions that will prevent the rope from winding properly. Wear

is

greatest at the

pickup point when the machine is accelerating.

If

this happens, the surface

should be repaired by machining or replaced. The winding should be checked to

make sure that the rope is winding

"thread wound" (Fig. 33).

Excessive wear in grooved drums should be checked for variations either in

the depth or pitch

of

the grooves.

No matter what type

of

drum is in use, excessive drum wear will result in poor

spooling and rope deterioration. This condition will accelerate rapidly when

winding in multiple layers.

STRENGTH LOSS

OF

WIRE

ROPE

OVER

STATIONARY

SHEAVES

OR

PINS

Rope breaking strength is determined in a standard test wherein fittings are

attached to the ends

of

the rope and the rope is pulled in a straight line.

If,

how-

ever, the rope passes over a curved surface (such as a sheave or pin) its strength

"is decreased." The amount

of

such reduction will depend on the severity

of

the

bend as expressed by the

Did

ratio. A rope bent around a pin

of

its own diameter

will have only

50%

of

the strength attributed to it in the standard test. This is

called

"50% efficiency" (Fig. 38). Even at Did ratios

of

40, there may be a loss

of

up to 5%.

At

smaller

Did

ratios, the loss in strength increases rapidly.

The angle

of

bend need not be 180°,90°, or even 45°; relatively small bends

can cause loss

of

strength.

Reduction

in

efficiency

of

wire

rope

when

bent

over pins

of

various sizes

50

60

~

1:;

70

z

w

U

G:

b

80

90

100

\

"\

-

--

---

"

J"

i

I

j

2 6

~~~-

-,-.--~

r-

---

~i

L

~

I

I

I

I

I

i I

10

14

18

22

26

30

34 38

Old RATIO

58 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...