4 - 36 Issued: November 2005RT700 Series

MAINTENANCE AND LUBRICATION

Desiccant cartridge life will vary depending on operating conditions, speeds, loads, air usage and compressor con-

dition. It is recommended that the desiccant cartridge be replaced approximately every 2 years. If system perfor-

mance is reduced, desiccant cartridge replacement is necessary. It is also recommended that the desiccant

cartridge be replaced if the compressor has been rebuilt.

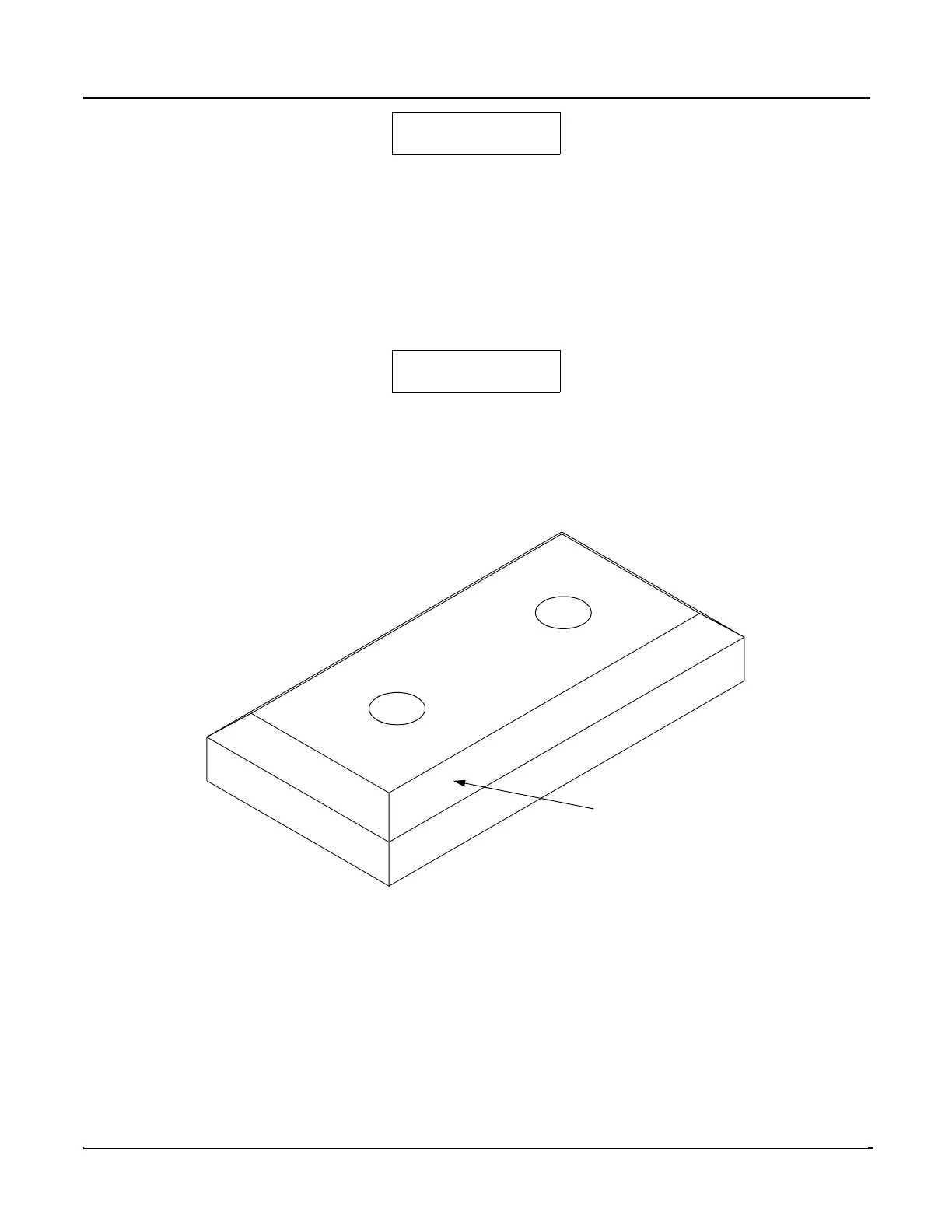

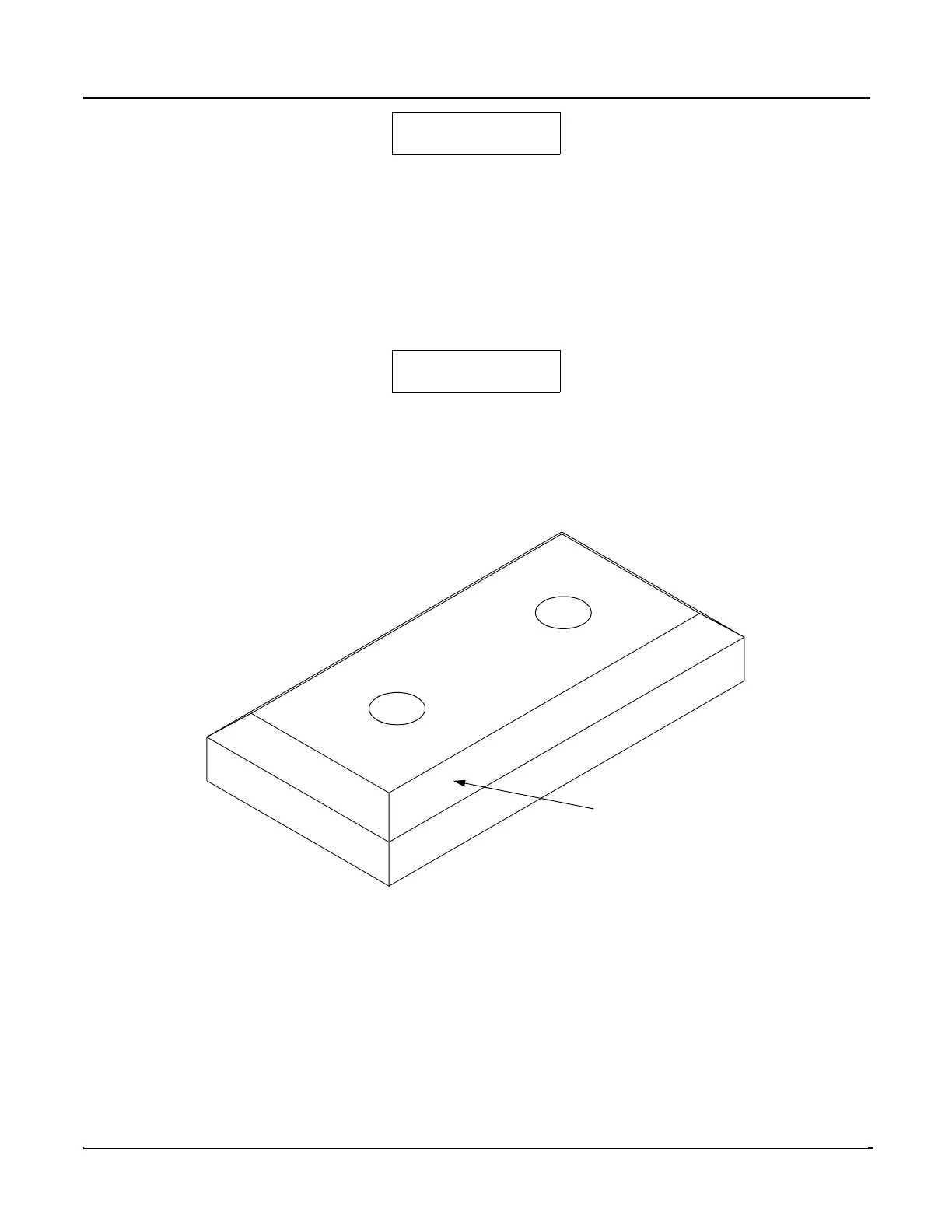

The front bottom slider pad should be checked daily for wear. The remainder of the slider pads should be checked

monthly for wear.

All the slider pads contain a chamfer on the wearing surface. When this chamfer is worn off, the slider pad must be

replaced.

With boom extended brush grease on areas of boom where wear pads contact is evident. he inside of the top plate

of all sections except the tip section also require grease. This can be applied through the holes in the side plates

and “piled” on top of the next section out just in front of the top rear pads on that section so that extending the boom

to the next hole smears the grease onto the inside of the top plate. Remember to do both sides.

Grease intervals vary and should be more frequent if noise or jerking of the boom is evident.

Chamfer

AIR DRYER

SLIDER PADS

Loading...

Loading...