ELASTIC STRETCH

Elastic stretch results from recoverable deformation

of

the steel itself. Here, again, a quantity cannot be precisely

calculated. However, the following equation can provide a reasonable approximation for a good many situations.

Changes in length

(ft)-

Change in load (lb) x Length (ft)

Area (inches

2

)x

Modulus

of

Elasticity (psi)

The modulus

of

elasticity is given in Table 17, and the area can be found in Table 18.

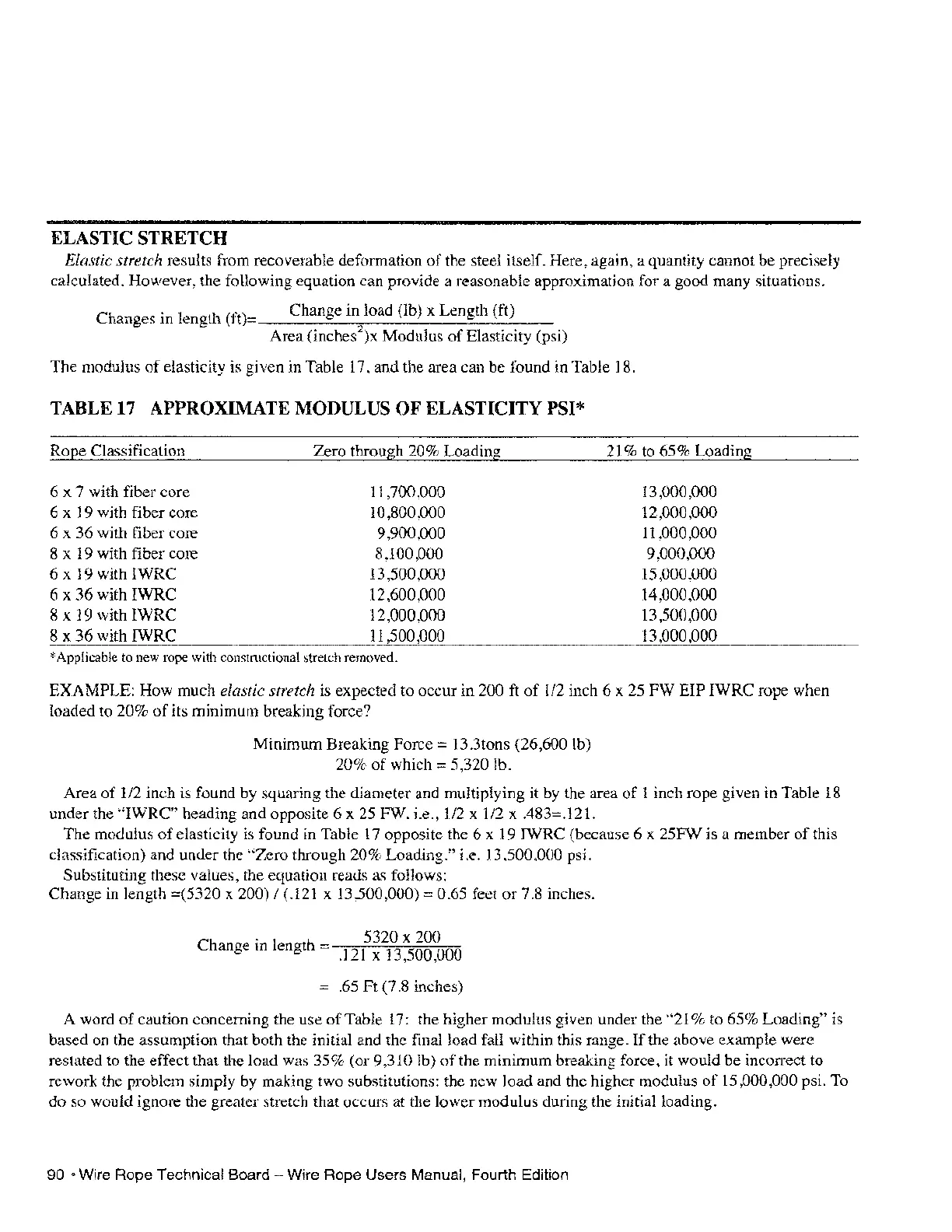

TABLE 17 APPROXIMATE MODULUS

OF

ELASTICITY PSI*

Rope Classification Zero through 20% Loading

21

% to 65% Loading

6 x 7 with fiber core

11,700,000

13,000,000

6 x

19

with fiber core 10,800,000

12,000,000

6 x 36 with fiber core 9,900,000 11,000,000

8 x

19

with fiber core 8,100,000 9,000,000

6 x 19 with IWRC 13,500,000 15,000,000

6 x 36 with IWRC 12,600,000

14,000,000

8 x

19

with IWRC 12,000,000

13,500,000

8 x 36 with IWRC 11,500,000

13,000,000

* Applicable to new rope with constructional stretch removed.

EXAMPLE: How much elastic stretch is expected to occur in 200 ft

of

112

inch 6 x 25

FW

ElP

IWRC rope when

loaded to

20%

of

its minimum breaking force?

Minimum Breaking Force = 13.3tons

(26,600 Ib)

20%

of

which = 5,320 lb.

Area

of

112

inch is found by squaring the diameter and multiplying it by the area

of

1 inch rope given

in

Table

18

under the "IWRC" heading and opposite 6 x

25

FW, i.e.,

112

x

112

x .483=.121.

The modulus

of

elasticity

is

found in Table

17

opposite the 6 x 19 IWRC (because 6 x 25FW is a member

of

this

classification) and under the

"Zero through 20% Loading." i.e. 13,500,000 psi.

Substituting these values, the equation reads as follows:

Change

in

length =(5320 x 200) / (.121 x 13,500,000) = 0.65 feet

or

7.8 inches.

5320 x 200

Change in length =

.121

x 13,500,000

=

.65

Ft (7.8 inches)

A word

of

caution concerning the use

of

Table

17:

the higher modulus given under the "21 % to 65% Loading" is

based on the assumption that both the initial and the final load fall within this range.

If

the above example were

restated to the effect that the load was 35% (or

9,310

Ib)

of

the minimum breaking force, it would be incorrect to

rework the problem simply by making two substitutions: the new load and the higher modulus

of

15,000,000 psi. To

do

so would ignore the greater stretch that occurs at the lower modulus during the initial loading.

90 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...