Care must be exercised when installing wire rope on the

winch drum. Improper spooling can result in winch damage

through crushing, kinking, doglegs, abrasion, and cutting.

Poorly installed wire rope will also adversely affect the

operating characteristics of the machine by causing uneven

application of force and motion. This can cause premature

fatiguing and failure of the rope.

Thoroughly inspect and clean the winch before proceeding

with the installation. CHeck the lagging and drum flanges

for cracks, breaks, and excessive wear. Deformed or out-

sized drum and excessive undercutting at the base of the

flange also indicate the repair or replacement of the drum is

necessary.

Check the bearings for excessive wear or play.

After correcting any defects revealed by the inspection and

determining that the winch is in good operating condition,

spool the wire rope as follows:

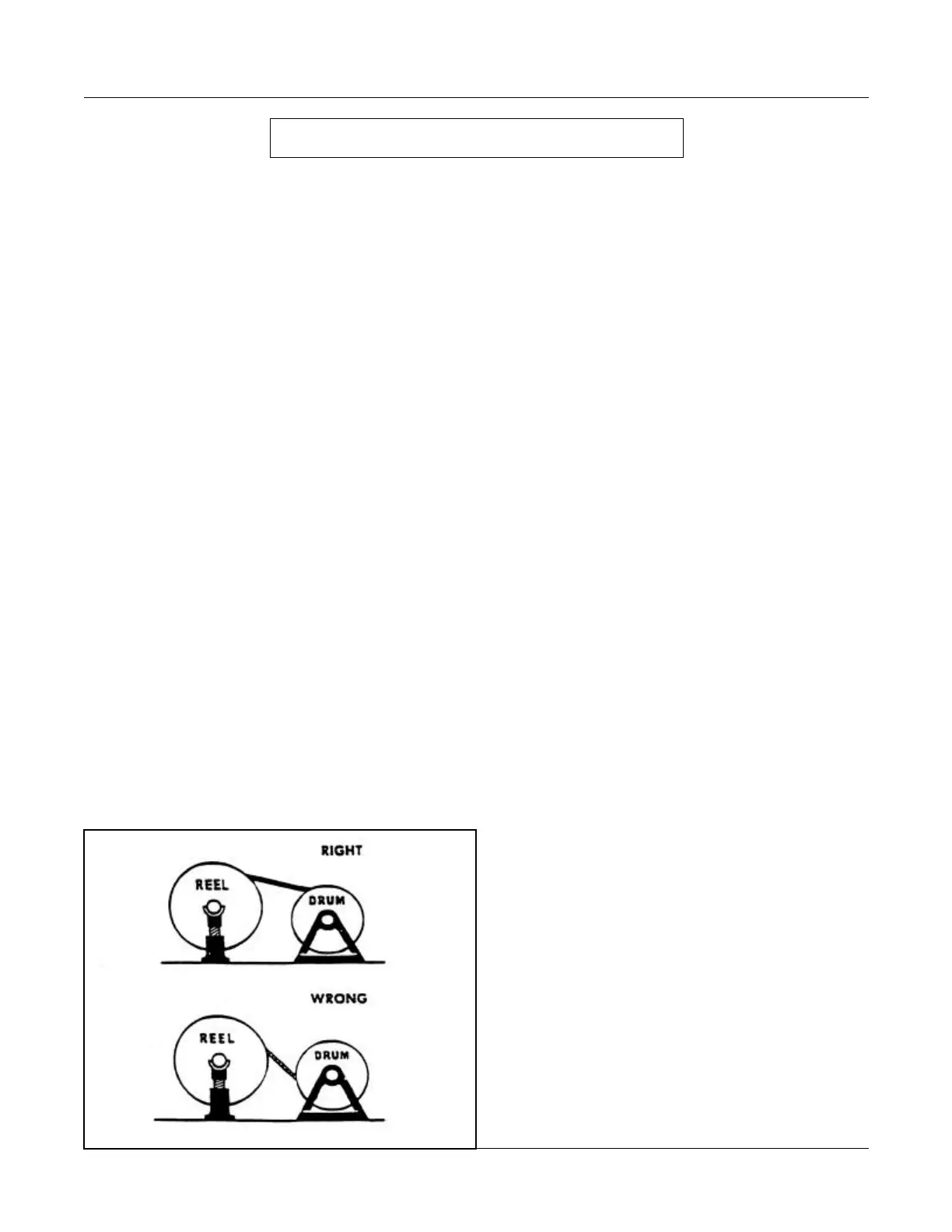

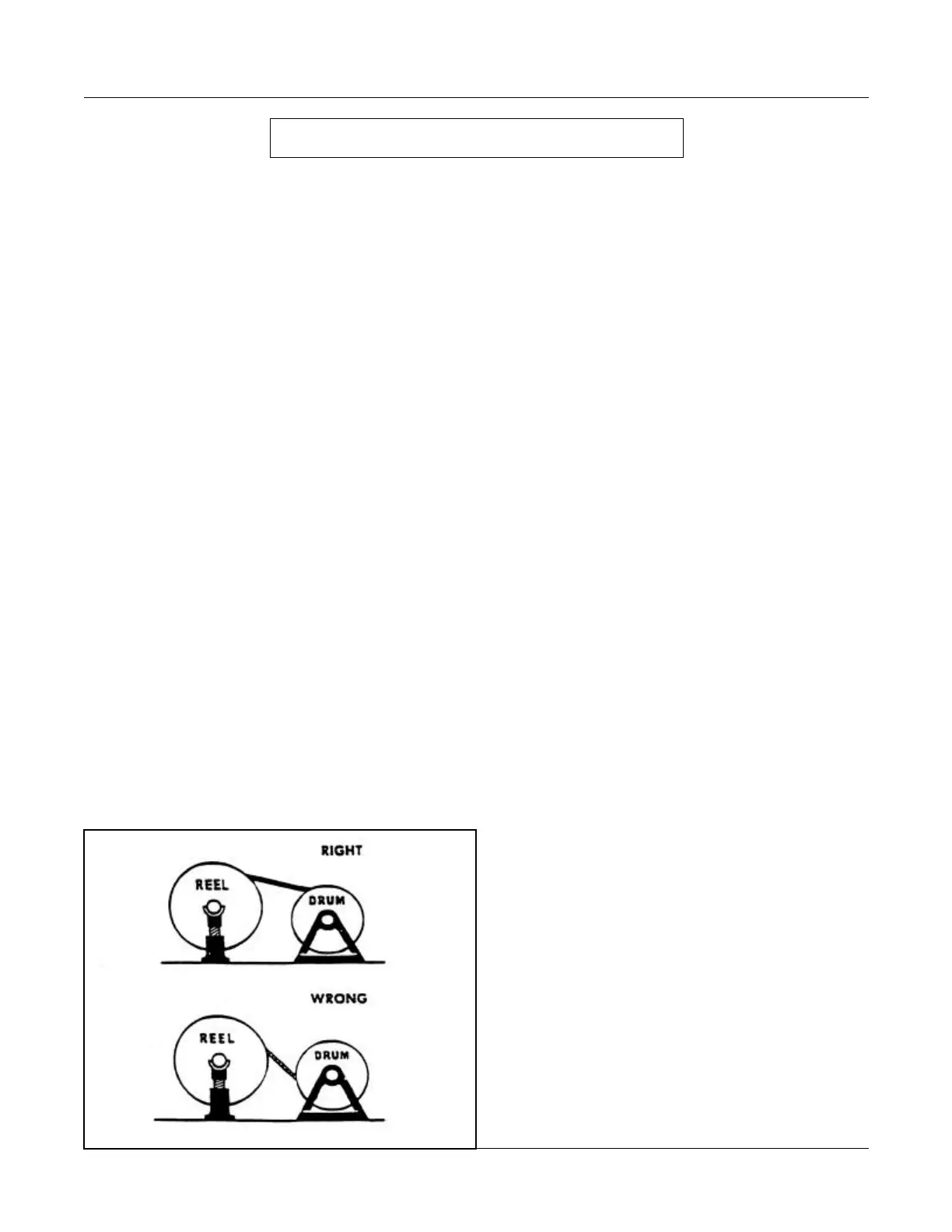

Mount the cable shipping reel vertically on jacks or a suit-

able supporting structure, with a pipe or bar through the reel

center. The cable should be drawn from the top of the reel,

as shown, in order to avoid reverse bending as it is spooled

onto the winch drum.

If cable is wound from the storage reel onto the drum, the

reel should be rotated in the same direction as the hoist.

Install cable on the winch drum in accordance with the fol-

lowing procedure.

1. Position the cable over the boom nose sheave and route

back to the winch drum.

2. Position the winch drum with the cable anchor slot on

top.

3. Insert cable through slot and position around the cable

wedge.

4. Position the anchor wedge in the drum slot; pull firmly

on the free end of the cable to secure the wedge.

5. Slowly rotate the drum, ensuring the first layer of cable

is evenly wound onto the drum.

6. Install the remainder of cable, as applicable.

The end of the cable should be even with the bottom of the

anchor wedge.

Apply breaking force to the reel flange in order to prevent

overrun as the rope is being drawn off. Loops formed by

overrun can cause kinks and doglegs in the rope, resulting

in damage and premature rope failure. A timber or block

forced against the shipping reel flange can be used to pro-

vide the required braking force.

Note: If the wedge does not seat securely in the slot, care-

fully tap the top of the wedge with a mallet.

SPOOLING WIRE ROPE ON DRUMS

SERVICE AND ADJUSTMENTS

Issued: August 20036 - 23RT700 Series

Loading...

Loading...