FLATTENED (TRIANGULAR) STRAND WIRE ROPE f.

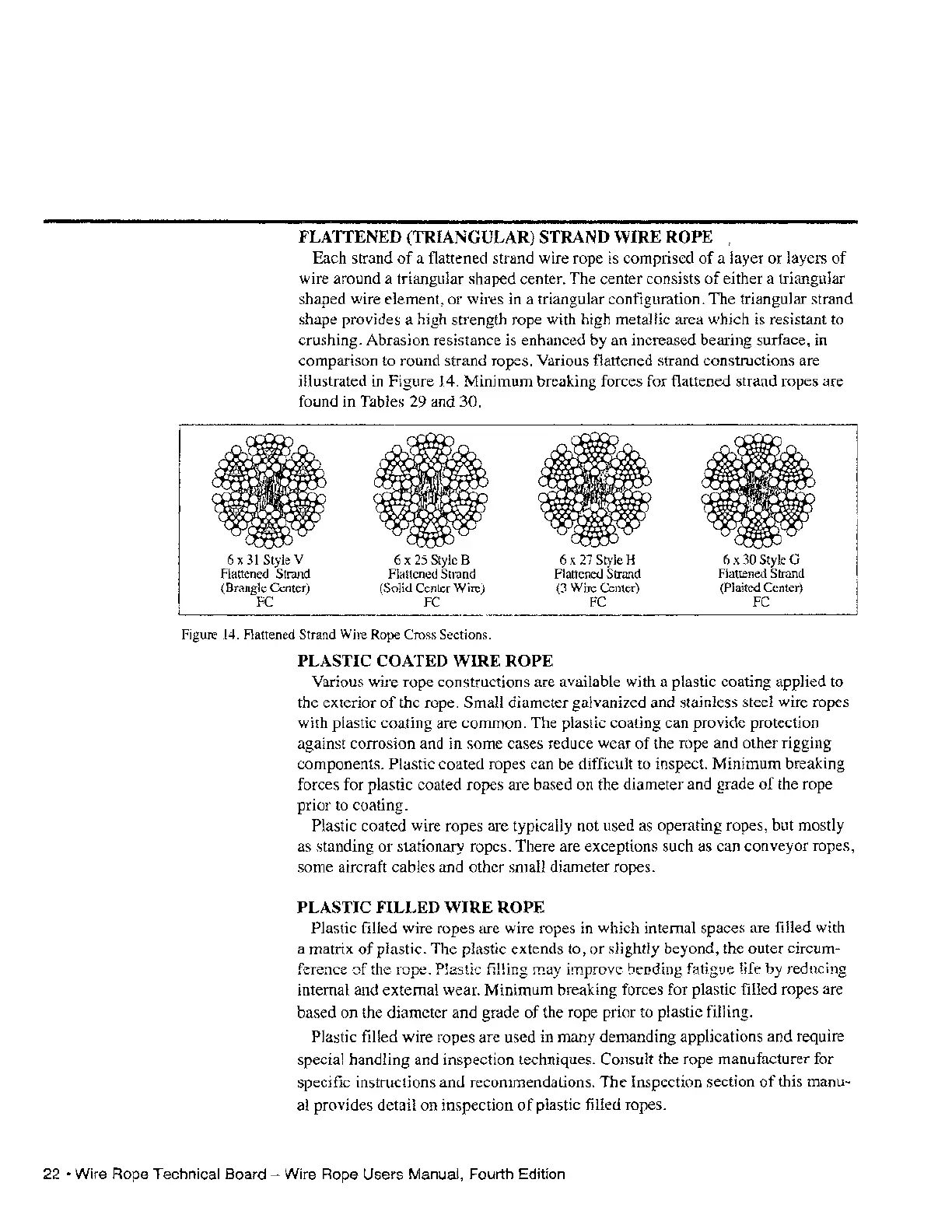

Each strand

of

a flattened strand wire rope

is

comprised

of

a layer or layers

of

wire around a triangular shaped center. The center consists

of

either a triangular

shaped wire element, or wires in a triangular configuration. The triangular strand

shape provides a high strength rope with high metallic area which is resistant to

crushing. Abrasion resistance is enhanced by an increased bearing surface, in

comparison to round strand ropes. Various flattened strand constructions are

illustrated

in

Figure 14. Minimum breaking forces for flattened strand ropes are

found in Tables 29 and

30.

6x31

Style V

Flattened Strand

(Brangle Center)

FC

6 x25 Style B

Flattened

Strand

(Solid

Center Wire)

FC

Figure 14. Flattened

Strand Wire Rope Cross Sections.

PLASTIC COATED WIRE ROPE

6x27

Style H

Flattened Strand

(3

Wire Center)

FC

6x

30

StyleG

Flattened Strand

(Plaited

Center)

FC

Various wire rope constructions are available with a plastic coating applied to

the exterior

of

the rope. Small diameter galvanized and stainless steel wire ropes

with plastic coating are common. The plastic coating can provide protection

against corrosion and in some cases reduce wear

of

the rope and other rigging

components. Plastic coated ropes can be difficult to inspect. Minimum breaking

forces for plastic coated ropes are based on the diameter and grade

of

the rope

prior to coating.

Plastic coated wire ropes are typically not used as operating ropes, but mostly

as standing or stationary ropes. There are exceptions such

as

can conveyor ropes,

some aircraft cables and other small diameter ropes.

PLASTIC FILLED WIRE ROPE

Plastic filled wire ropes are wire ropes in which internal spaces are filled with

a

matrix

of

plastic. The plastic extends to, or slightly beyond, the outer circum-

ference

of

the rope. Plastic filling may improve bending fatigue life by reducing

internal and external wear. Minimum breaking forces for plastic filled ropes are

based on the diameter and grade

of

the rope prior to plastic filling.

Plastic filled wire ropes are used in many demanding applications and require

special handling and inspection techniques. Consult the rope manufacturer for

specific instmctions and recommendations. The Inspection section

of

this manu-

al provides detail on inspection

of

plastic filled ropes.

22 • Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

Loading...

Loading...