Issued: July 2003

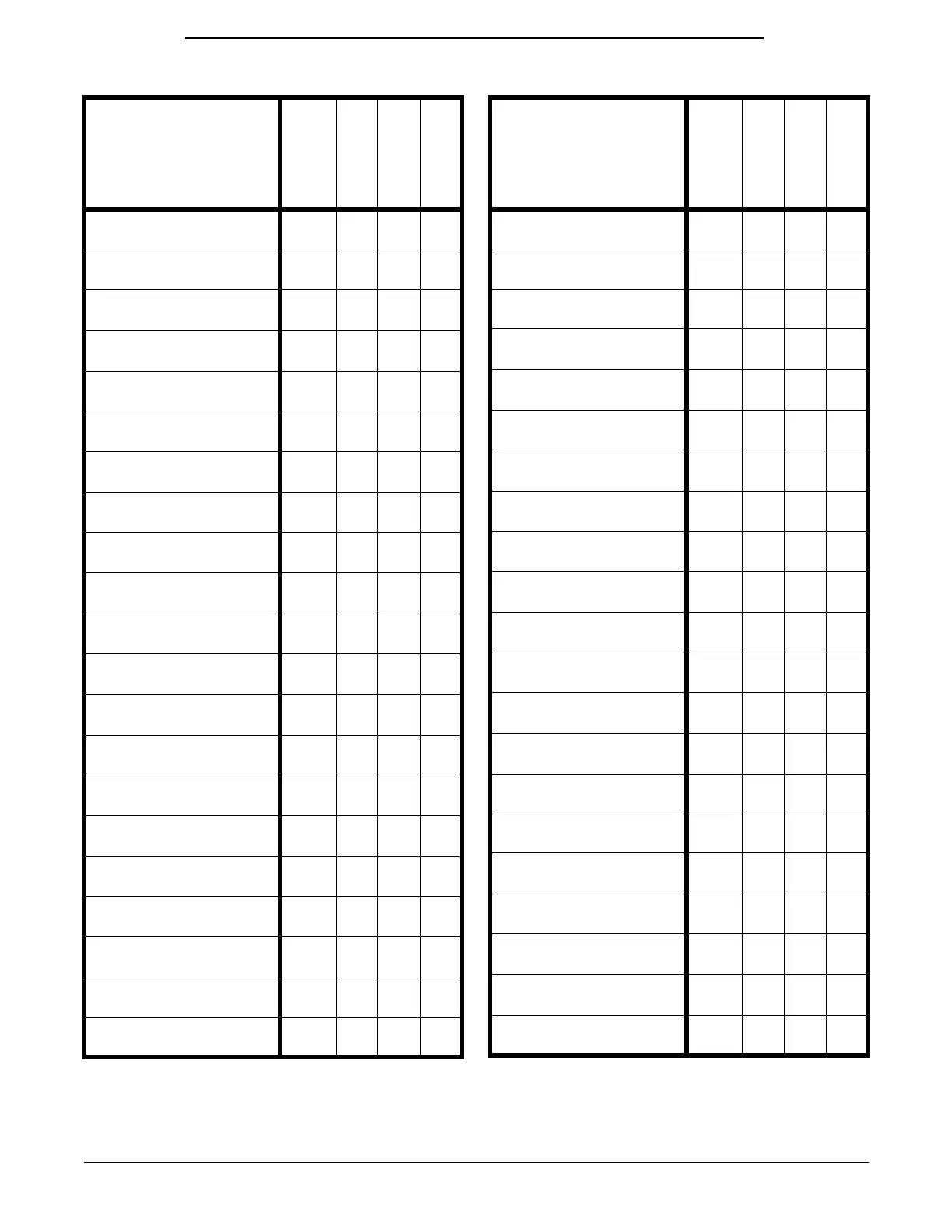

ITEMS TO BE

INSPECTED

& CHECKED

INSPECTION

CODE

SATISFACTORY

ADJUST

REPAIR

VISUAL INSPECTION H

(Complete Machine)

D

OVERALL

CLEANLINESS

D

HYDRAULIC SYSTEM

(Leaks or Damage)

D

AIR SYSTEM

(Leaks or Damage)

D

HYDRAULIC

FLUID

D

AXLE LOCKOUT

SYSTEM

D

TRANSMISSION

FLUID LEVEL

D

ENGINE CRANKCASE

FLUID LEVEL

D

FUEL TANK

FLUID LEVEL

D

RADIATOR

FLUID LEVEL

D

MACHINE

LUBRICATION

D

ATTACHMENT

PIN BOLTS

D

MUFFLER/EXHAUST

SYSTEM

D

ALL CONTROL

MECHANISMS

D

INSTRUMENT

GAUGES

D

CLUTCHES

& BRAKES

D

WIRE ROPE, SHEAVES

& GUARDS

D

TWO BLOCK DAMAGE

PREVENTION SYSTEM

D

LOAD SUPPORTING

COMPONENTS CONDITION

D

FIRE EXTINGUISHER

D

BACKUP ALARM

D

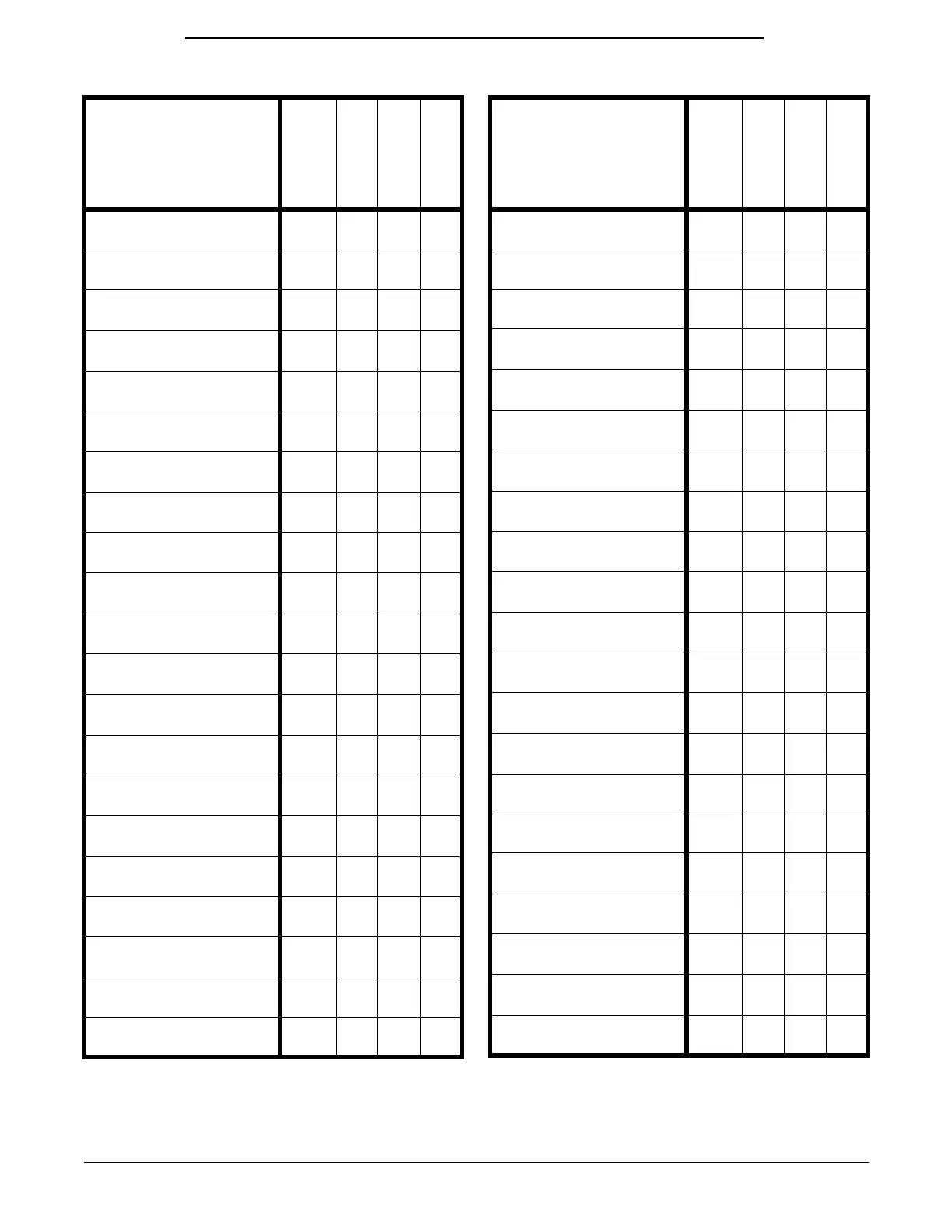

ITEMS TO BE

INSPECTED

& CHECKED

INSPECTION

CODE

SATISFACTORY

ADJUST

REPAIR

BOOM ANGLE

INDICATOR

D

HEAD/TAIL/BRAKE LIGHTS

& 4 - WAY FLASHERS

D

HORN

D

CABLE SPOOLING

PROPERLY

D

WEDGE

SOCKETS

D

AXLE FLUID

LEVEL

W

SWING REDUCER

FLUID LEVEL

W

DRIVE SHAFTS

& U JOINTS

W

TIRE & WHEEL CONDITION &

INFLATION PRESSURE

W

AIR

REGULATORS

W

AIR CLEANER

ELEMENT

W

CLUTCH & BRAKE

LINKAGE & PINS

W

WHEEL LUG

NUT TORQUE

W

FAN BELT

TENSION

W

STRUCTURAL MEMBERS &

WELDS

W

BOOM INSPECTION

W

BATTERIES &

STARTING SYSTEM

M

ALCOHOL

EVAPORATOR

M

SWING BEARING

BOLT TORQUE

P

MACHINERY

GUARDS

P

LOAD CHART &

SAFETY WARNINGS

P

SUGGESTED ROUGH TERAIN CRANE INSPECTION CHECK LIST

This check list is to be used in addition to the information provided in this manual to properly operate and maintain the

machine.

H Inspect OVERALL machine (including carrier) for cracks, weld separation, leaks, damage, vandalism.

INSPECTION CODE INTERVALS

D - DAILY M - MONTHLY

W - WEEKLY P - PERIODIC

NOTES:

1. Indicate inspection result by checking in the satisfactory, adjust, or repair boxes provided.

2. When appropriate, enter your diagnosis on back of page for repairs or adjustments made.

Issued: July 2003

Loading...

Loading...