Appendix E

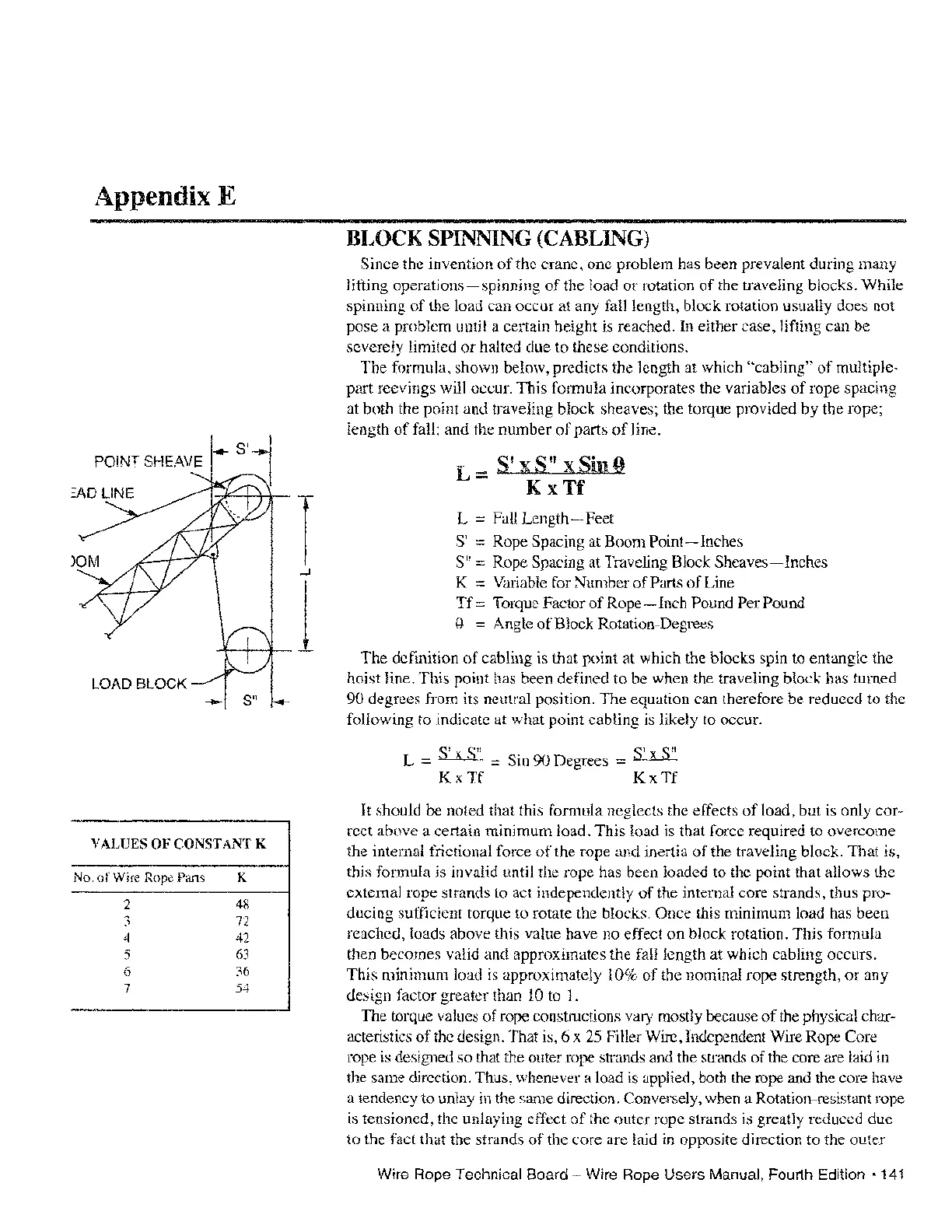

POINT SHEAVE

LOAD BLOCK

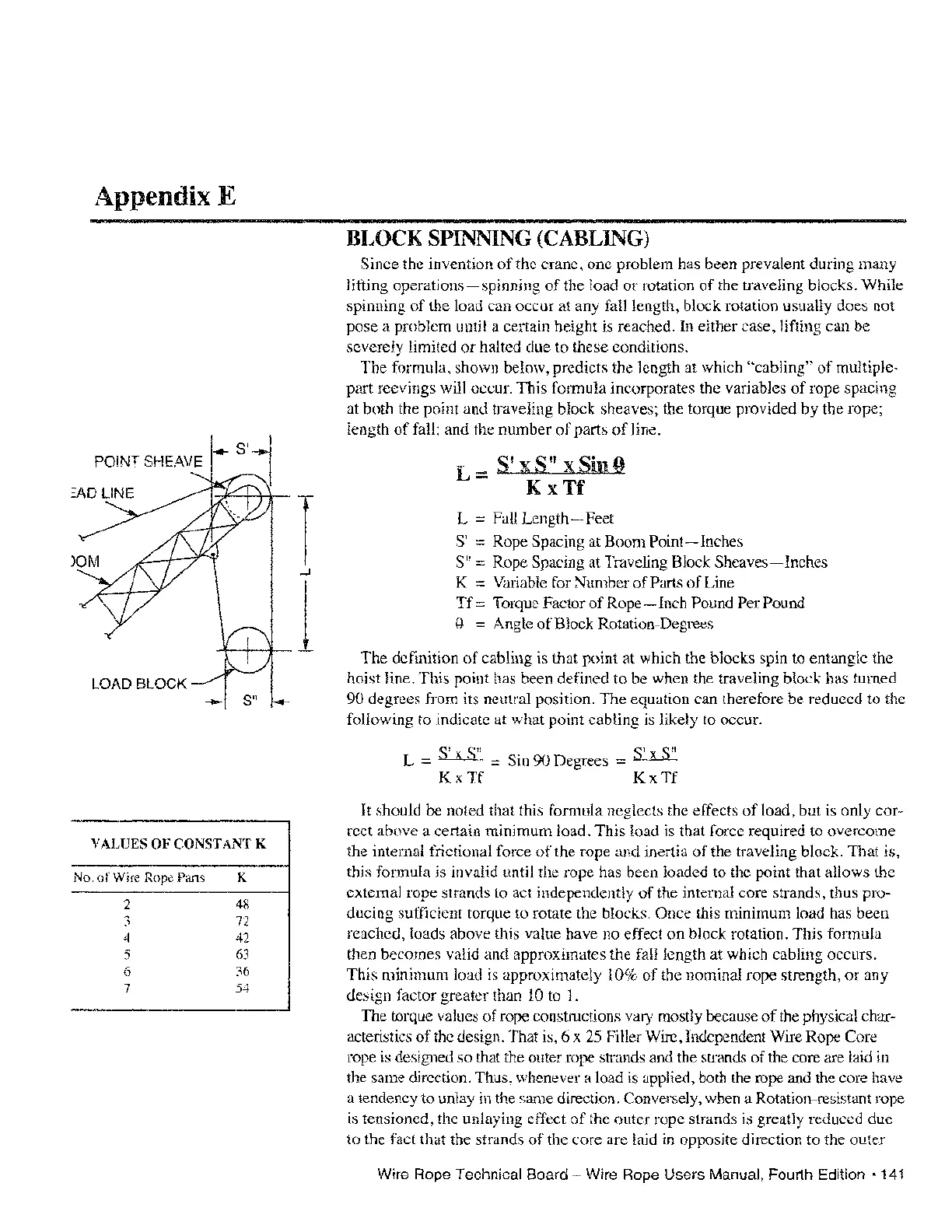

VALVES

OF

CONSTANT K

No.

of

Wire Rope Parts K

2

48

3 72

4

42

5

63

6 36

7 54

BLOCK

SPINNING (CABLING)

Since the invention

of

the crane, one problem has been prevalent during many

lifting

operations-spinning

of

the load

or

rotation

of

the traveling blocks. While

spinning

of

the load can occur at any fall length, block rotation usually does not

pose a problem until a certain height

is reached.

In

either case, lifting can be

severely limited

or

halted due to these conditions.

The formula, shown below, predicts the length at which

"cabling"

of

multiple-

part reevings will occur. This formula incorporates the variables

of

rope spacing

at both the point and traveling block sheaves; the torque provided by the rope;

length

of

fall; and the number

of

parts

of

line.

_

SiX

S

II

X Sin Q

-

KxTf

L

==

Fall Length - Feet

S'

==

Rope Spacing at Boom

Point-Inches

S"

==

Rope Spacing at Traveling Block

Sheaves-Inches

K

==

Variable for Number

of

Pmts

of

Line

Tf::::

Torque Factor

of

Rope - Inch Pound Per Pound

Q.

==

Angle

of

Block Rotation-Degrees

The definition

of

cabling is that point at which the blocks spin to entangle the

hoist

line. This point has been defined to be when the traveling block has turned

90 degrees from its neutral position. The equation can therefore be reduced to the

following to indicate at what point cabling

is likely to occur.

S'

S"

S'

~

QII

L

==

_X_

==

Sin 90 Degrees

::::

b!....1LL

KxTf KxTf

It should be noted that this formula neglects the effects

of

load, but is only cor-

rect above a certain minimum load. This load is that force required to overcome

the internal frictional force

of

the rope and inertia

of

the traveling block. That is,

this formula is invalid until the rope has been loaded to the point that allows the

external rope strands to act independently

of

the internal core strands, thus pro-

ducing sufficient torque to rotate the blocks. Once this minimum load has been

reached, loads above this value have no effect on block rotation. This formula

then becomes

valid and approximates the fall length at which cabling occurs.

This minimum load is approximately 10%

of

the nominal rope strength,

or

any

design factor greater than

10

to

1.

The torque values

of

rope constructions vary mostly because

of

the physical char-

acteristics

of

the design. That is, 6 x

25

Filler Wire, Independent Wire Rope Core

rope

is

designed so that the outer rope strands and the strands

of

the core

m'e

laid in

the same direction. Thus, whenever a load is applied, both the rope andthe core have

a tendency to unlay

in the same direction. Conversely, when a Rotation-resistant rope

is tensioned, the unlaying effect

of

the outer rope strands is greatly reduced due

to the fact that the strands

of

the core are laid in opposite direction to the outer

Wire Rope Technical Board - Wire Rope Users Manual, Fourth Edition

'141

Loading...

Loading...