Wire Rope and Wire Rope Slings

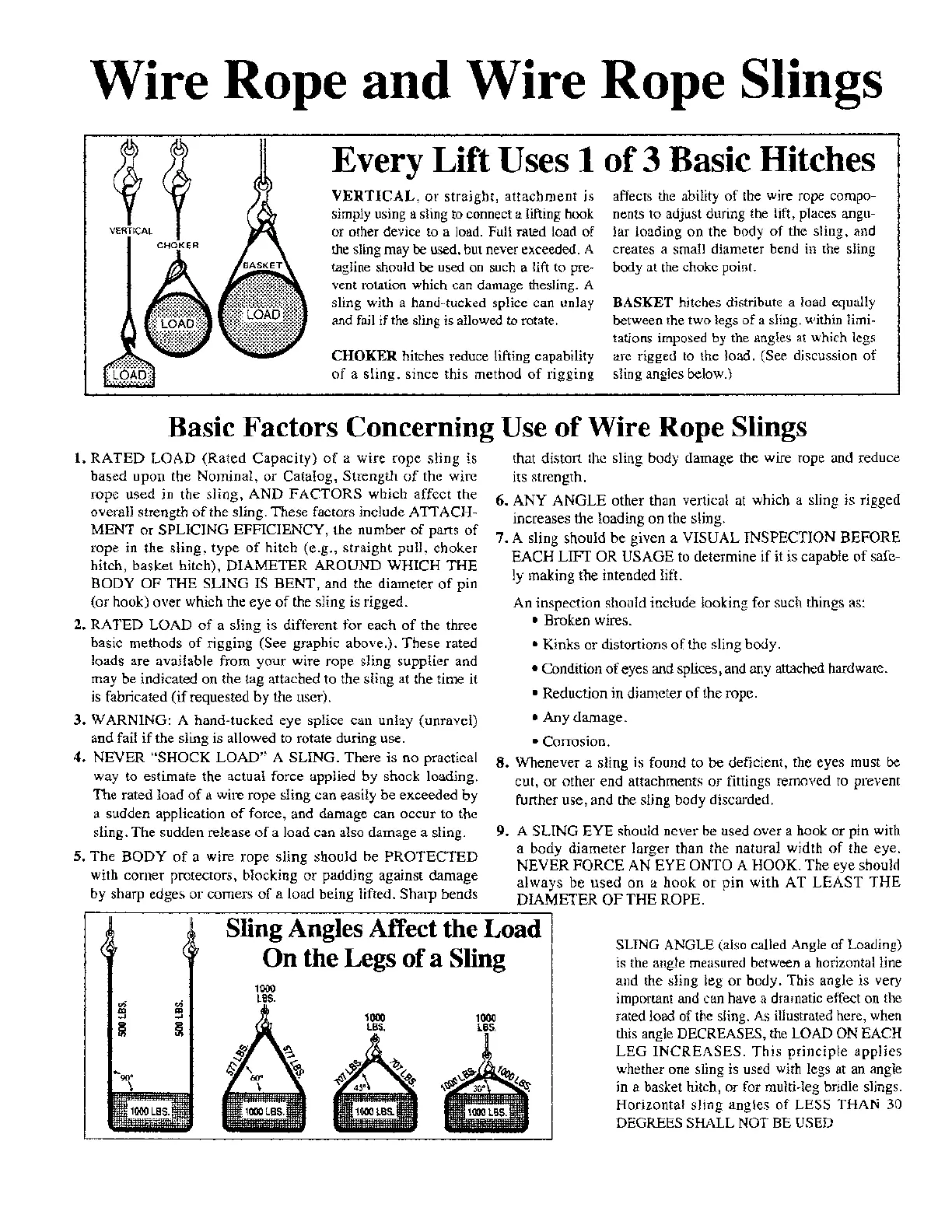

Every Lift Uses 1 of 3 Basic Hitches

VERTICAL,

or

straight,

attachment

is

simply using a sling to connect a lifting hook

or other device to a load. Full rated load of

the sling may be used, but never exceeded. A

tagline should be used

on

such a lift

to

pre-

vent rotation which can damage thesling. A

sling with a hand-tucked splice can unlay

and fail

if

the sling is allowed

to

rotate.

affects the ability of the wire rope compo-

nents to adjust during the lift, places angu-

lar loading on the body

of

the sling, and

creates a small diameter bend in the sling

body at the choke point.

BASKET hitches distribute a load equally

between the two legs of a sling, within limi-

tations imposed

by

the angles

at

which legs

are rigged to the load. (See discussion of

sling angles below.)

CHOKER hitches reduce lifting capability

of

a sling, since this method

of

rigging

Basic Factors Concerning Use

of

Wire Rope Slings

1.

RATED

LOAD

(Rated

Capacity)

of

a wire

rope

sling is

based upon the Nominal,

or

Catalog, Strength

of

the wire

rope used in the sling,

AND

FACTORS which affect the

overall strength

of

the sling. These factors include ATTACH-

MENT or

SPLICING EFFICIENCY, the number

of

parts

of

rope in the sling, type

of

hitch (e.g., straight pull, choker

hitch, basket hitch), DIAMETER AROUND WHICH THE

BODY

OF

THE SLING IS BENT, and the diameter

of

pin

(or hook) over which the eye

of

the sling is rigged.

2. RATED LOAD

of

a sling is different for each

of

the three

basic methods

of

rigging (See graphic above.). These rated

loads are available from your wire rope sling supplier and

may be indicated on the tag attached to the sling at the time it

is fabricated (if requested

by

the user).

3. WARNING: A hand-tucked eye splice can unlay (unravel)

and fail

if

the sling is allowed to rotate during use.

4. NEVER "SHOCK LOAD" A SLING. There is no practical

way to estimate the actual force applied by shock loading.

The rated load

of

a wire rope sling can easily be exceeded by

a sudden application

of

force, and damage can occur to the

sling. The sudden release

of

a load can also damage a sling.

S.

The

BODY

of

a wire rope sling should be

PROTECTED

with corner protectors, blocking

or

padding against damage

by sharp edges

or

corners

of

a load being lifted. Sharp bends

that distort the sling body damage the wire rope and reduce

its strength.

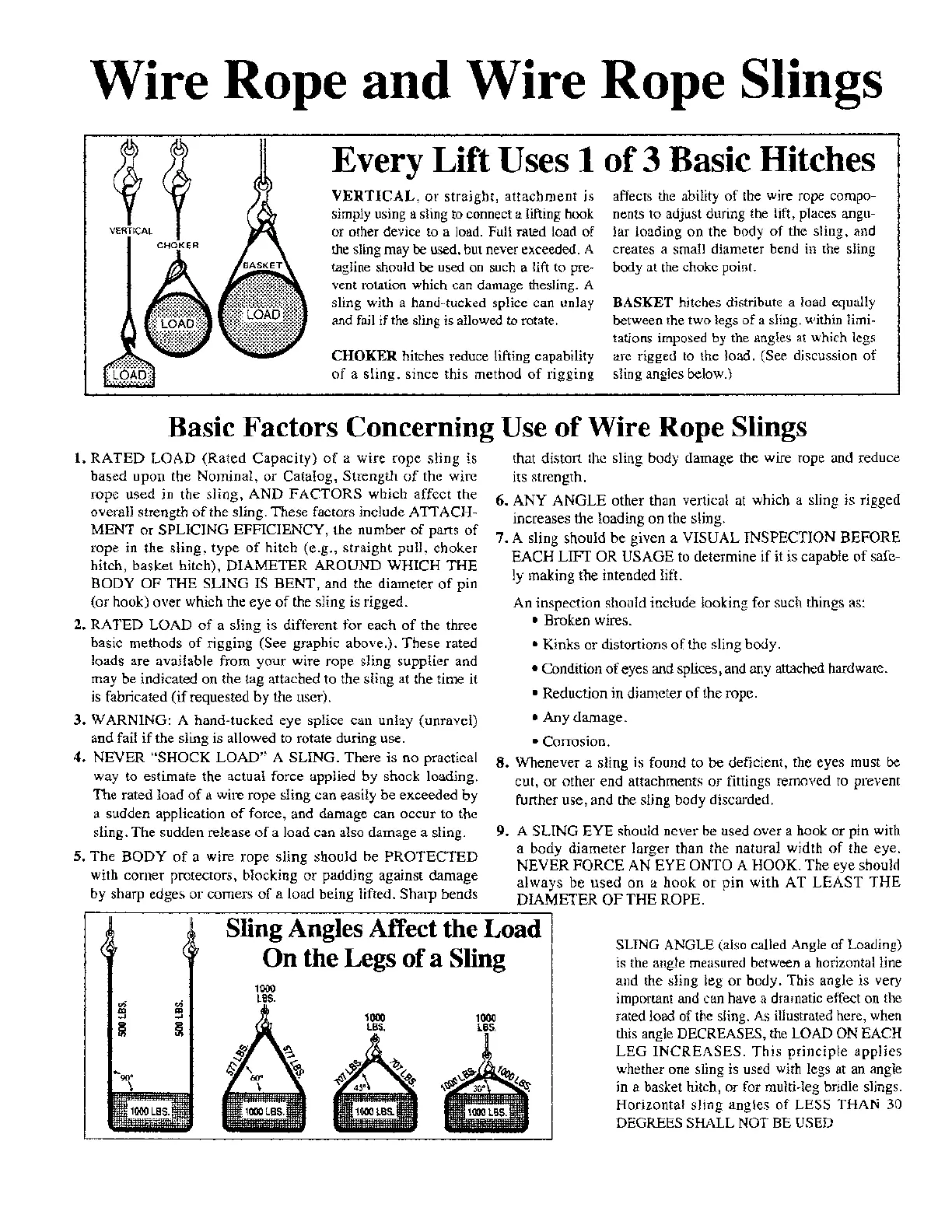

6. ANY ANGLE other than vertical at which a sling is rigged

increases the loading on the sling.

7. A sling should be given a VISUAL INSPECTION BEFORE

EACH LIFT

OR

USAGE to determine

if

it is capable

of

safe-

ly making the intended lift.

An

inspection should include looking for such things as:

• Broken wires.

• Kinks

or

distortions

of

the sling body.

• Condition

of

eyes and splices, and any attached hardware.

• Reduction in diameter

of

the rope.

• Any damage.

• Corrosion.

S.

Whenever a sling

is

found to be deficient, the eyes must be

cut,

or

other end attachments

or

fittings removed to prevent

further use, and the sling body discarded.

9. A SLING EYE should never be used over a hook

or

pin with

a

body

diameter larger than the natural width

of

the eye.

NEVER FORCE AN EYE ONTO A HOOK. The eye should

always

be

used

on

a

hook

or

pin

with

AT

LEAST

THE

DIAMETER

OF

THE ROPE.

Sling Angles Affect the

Load

On

the

Legs

of a Sling

SLING ANGLE (also called Angle of Loading)

is the angle measured between a horizontal line

and the sling leg or body. This angle is very

important and can have a dramatic effect on the

rated load of the sling.

As

illustrated here, when

this angle

DECREASES, the LOAD ON EACH

LEG

INCREASES.

This

principle

applies

whether one sling is used with legs at an angle

in a basket hitch, or for multi-leg bridle slings.

Horizontal sling angles

of

LESS THAN 30

DEGREES SHALL NOT BE USED

Loading...

Loading...