QUARTERLY:

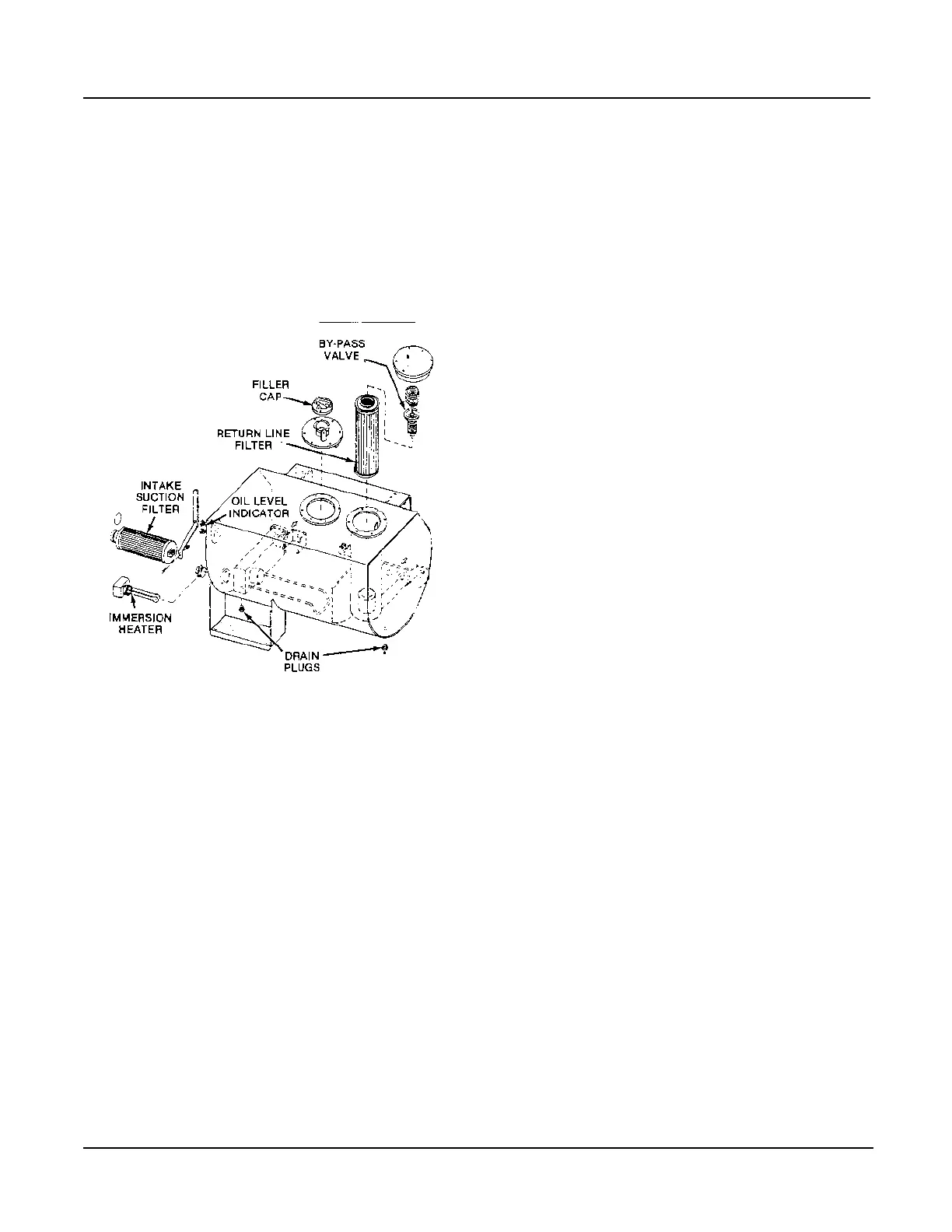

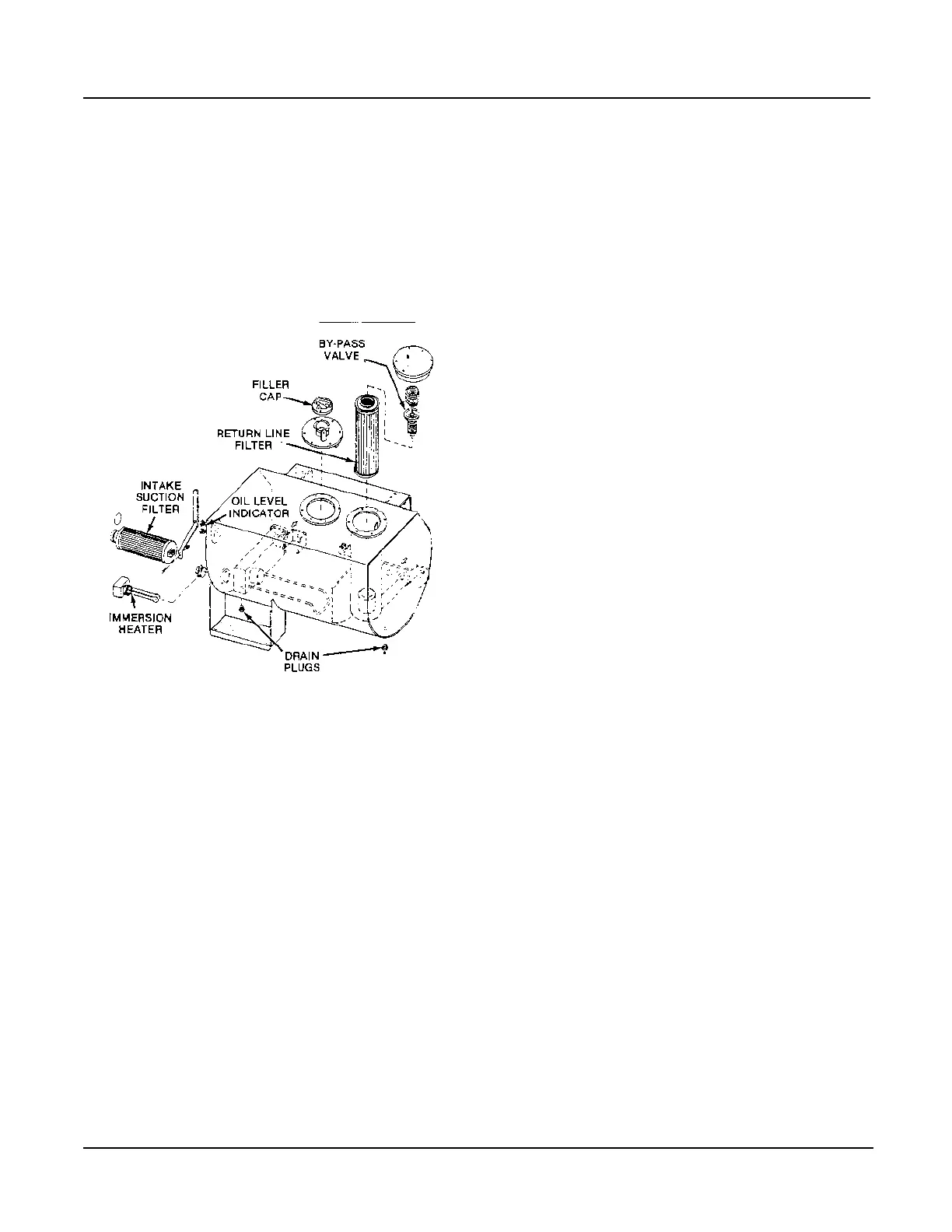

HYDRAULIC FILTER Remove and replace the hy-

draulic reservoir return line filters. Access is gained by

removing the cover plate on the reservoir.

When replacing the filters, clean the spring and bypass

valves. Inspect the gasket for damage and replace if

necessary.

Before discarding the old filter element, examine the

type of material trapped in it. This may indicate which,

if any, hydraulic system components are deteriorating.

SEMI ANNUALLY:

SUCTION FILTER Remove and clean the hydraulic

reservoir intake suction filter. This per- manent screen

type filter is located inside the reservoir on the intake to

the pump manifold. Access to the filter is accomplished

by removing the cover with filler neck and filter holding

device from the top of the reservoir. Move the lever to-

wards the front of the machine and lift out the filter.

Remove the “O” ring from the adapter and check it for

damage or deterioration. If the ring is at all damaged,

replace it.

Clean the filter by immersing it in a non-caustic clean-

ing solvent. Rub the screen surface with a soft brush to

dislodge accumulated foreign matter. Reinstall filter,

filter hold-down device and cover.

RESERVOIR RELIEF VALVE Check the hydraulic

reservoir relief valve for proper functioning. The valve

is located in the filler cap and is checked by extending

all the boom cylinders and then retracting them to

slightly pressurize the reservoir. When the cap is

turned to the first notch, air should be heard escaping

if the system is holding pressure. The system is sealed

and has a relief valve pressure setting of 14 psi.

1500 HOURS:

HYDRAULIC RESERVOIR Drain and clean the hy-

draulic reservoir. Change the hydraulic oil.

A change interval cannot be established which would

apply to all oils and all operating conditions of temper-

ature and cleanliness. However, a reputable brand of

turbine grade oil can be ex- pected to deliver 1500

hours of service under average operating conditions.

Although conditions may necessitate shorter change

intervals, do not use hydraulic oil for more than 1500

hours.

Whenever a visual inspection, chemical test or light

test indicates that an oil change is necessary, proceed

as follows:

1. Warm the oil prior to draining but avoid draining im-

mediately after prolonged continuous use to reduce

the danger of being burned by hot oil.

2. Retract all cylinders to return the maximum amount

of oil to the reservoir. Loosen the top covers and re-

move the drain plug(s) at the bot- tom of the reservoir.

Allow sufficient time for the reservoir to drain thorough-

ly.

3. Remove the return filters, clean springs, bypass

valves and inspect cover gasket for damage and dete-

rioration. Replace gasket if necessary.

MAINTENANCE AND LUBRICATION

4 - 20 Revised: March 2005RT700 Series

Loading...

Loading...