Note:Replacethegasketorscreenorbothifthese

partsarewornordamaged

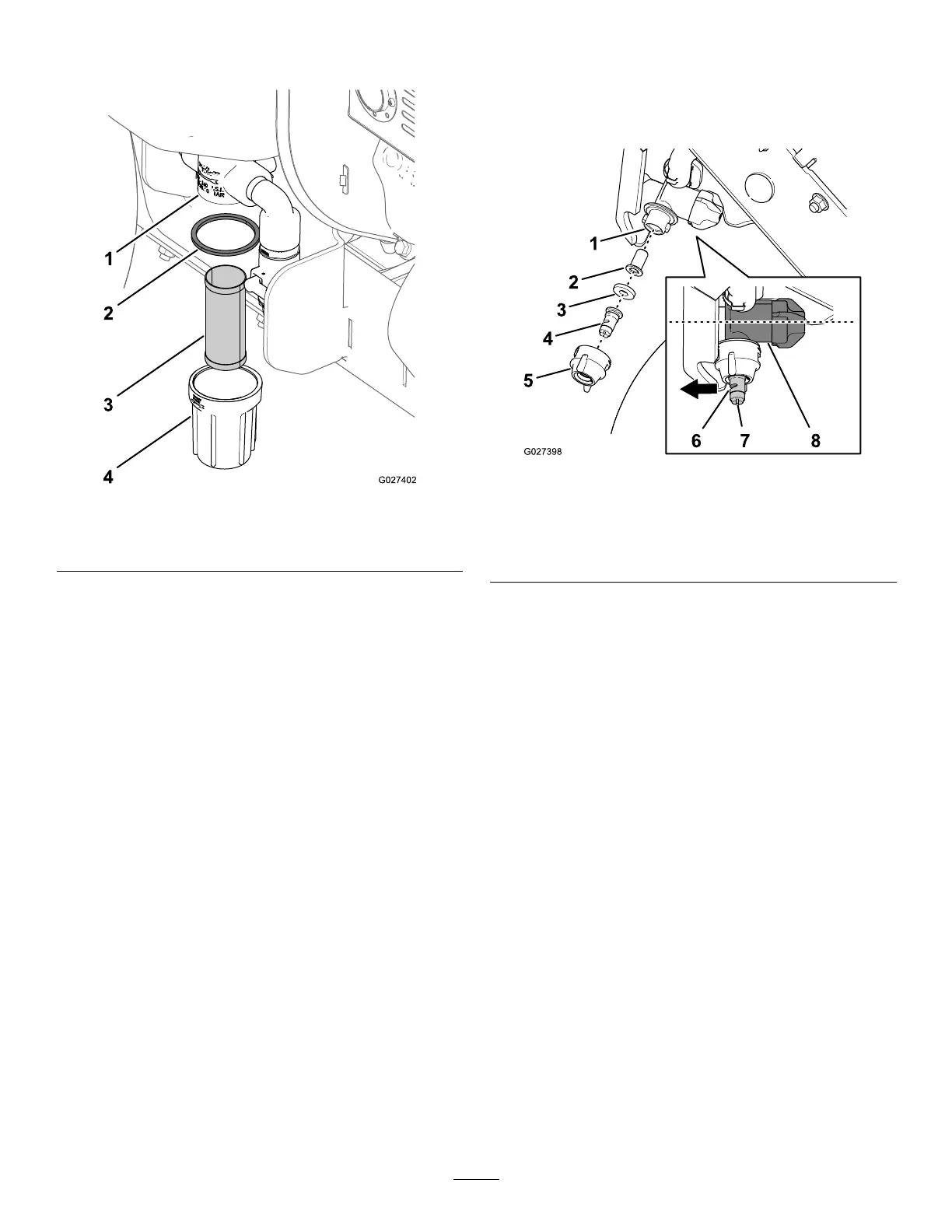

Figure48

1.Strainerbody3.Screen

2.Gasket

4.strainerbowl

5.Allowanyresidualchemicalsolutiontodrainfromthe

strainerbody.

Note:Disposeofthewastesolutionaccordingtolocal

codesandthechemicalmanufacturer'sinstructions.

6.Useasoft-bristlebrushandcleanwatertocleanthe

screenandbowl

7.Installthescreenintothestrainerbody(.Figure48).

8.Installthestrainerbowlontothestrainerbodyand

handtightenthebowl(Figure48).

9.Rotatethehandleforthesupplyvalve90°clockwise

(Figure47).

CleaningtheSprayerNozzle

ServiceInterval:Aftereachuse

1.Rotatethenozzlecap90°counterclockwiseand

removethecapfromthenozzlebody(Figure49).

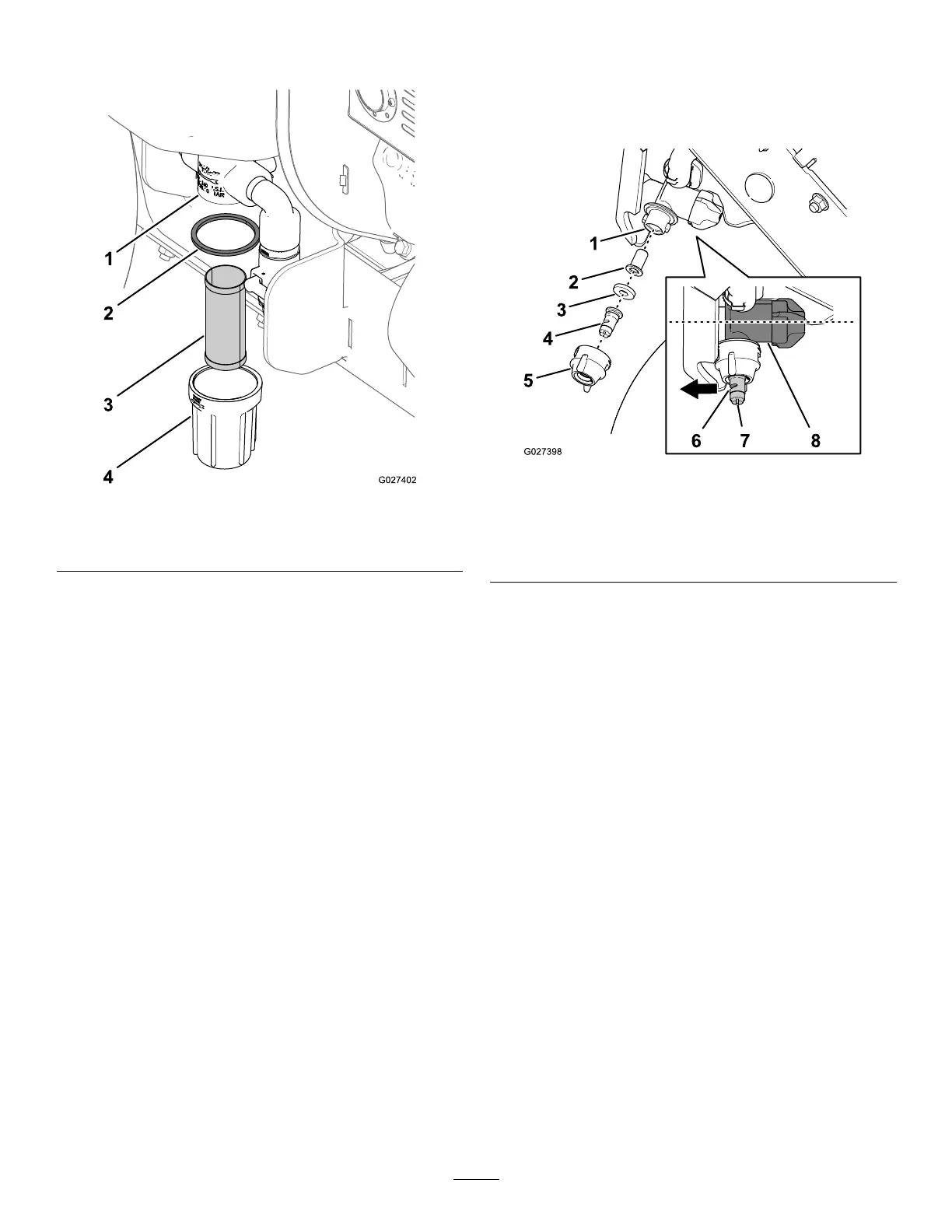

Figure49

1.Nozzlebody5.Nozzlecap

2.Strainer

6.Atomizer

3.Gasket7.Slot

4.Sprayertip

8.Regulatorcase

2.Removethesprayertip,gasket,andstrainerfromthe

nozzlebody(Figure49).

Note:Replaceanywornordamagednozzleparts.

3.Useasoft-bristlebrushandcleanwatertocleanthe

nozzletip,gasket,andstrainer.

4.Assemblethestrainerintothenozzlebody(Figure49).

5.Assemblethesprayertipandgasketintothenozzle

cap(Figure49).

6.Installthetip,gasket,andcapontothenozzlebody

(.Figure49).

Note:Usetheslottorotatetheatomizer(Figure49)of

thesprayertipforward(in-linewiththeow-regulator

caseofthenozzlebody).

7.Rotatethenozzlecap90°clockwise(Figure49).

8.Repeatsteps1through7forthe2othersprayer

nozzles.

42

Loading...

Loading...