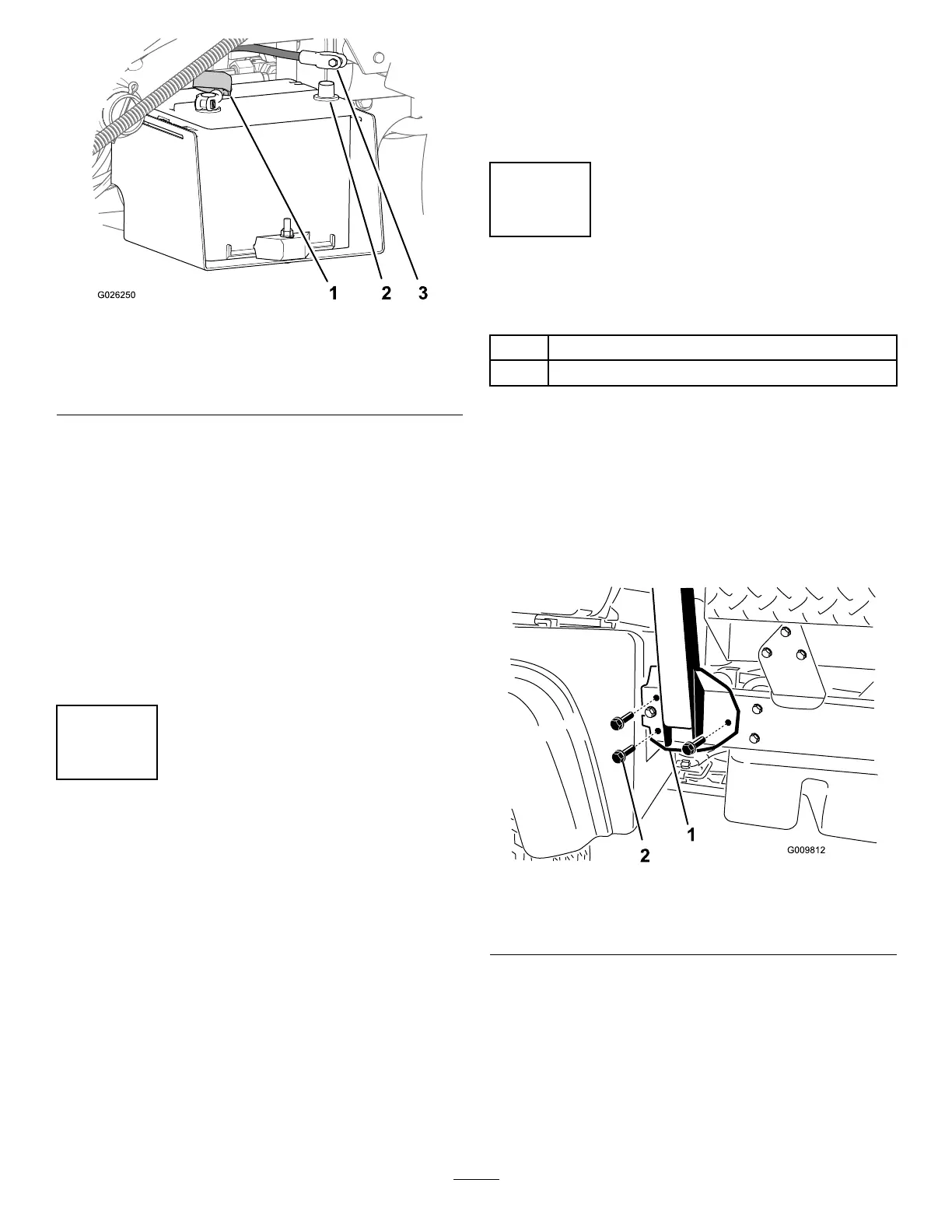

g026250

Figure5

1.Insulatorboot(positive

batterycable)

3.Negativebatterycable

(black)

2.Negativebatterypost

4.Slidetheinsulatorbootoverthepositive

terminal.

Note:Theinsulatorbootpreventsapossible

short-to-groundfromoccurring.

5.Connectthenegativebatterycable(black)tothe

negative(–)terminalofthebatteryandsecure

thecablewithboltsandnuts.

6.Alignthebatterycovertothebatterybase

(Figure4).

7.Squeezethebatterycover,alignthetabsto

thebatterybase,andreleasethebatterycover

(Figure4).

3

CheckingtheFluidLevels

andTirePressure

NoPartsRequired

Procedure

1.Checktheengine-oillevelbeforeandafter

yourststarttheengine;refertoCheckingthe

Engine-OilLevel(page41).

2.Checkthetransmission-uidlevelbeforeyou

rststarttheengine;refertoCheckingthe

Transmission-FluidLevel(page49).

3.Checktheengine-coolantlevelbeforeyou

rststarttheengine;refertoCheckingthe

Engine-CoolantLevel(page53).

4.Checkthebrake-uidlevelbeforeyourststart

theengine;refertoCheckingtheBrake-Fluid

Level(page56).

5.Checktheairpressureinthetires;referto

CheckingtheTirePressure(page21).

4

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbar

6

Flange-headbolt(1/2x1-1/4inches)

Procedure

1.Applymedium-grade(service-removable)

thread-lockingcompoundtothethreadsofthe6

ange-headbolts(1/2x1-1/4inches).

2.Aligneachsideoftherollbarwiththemounting

holesoneachsideofthemachineframe(Figure

6).

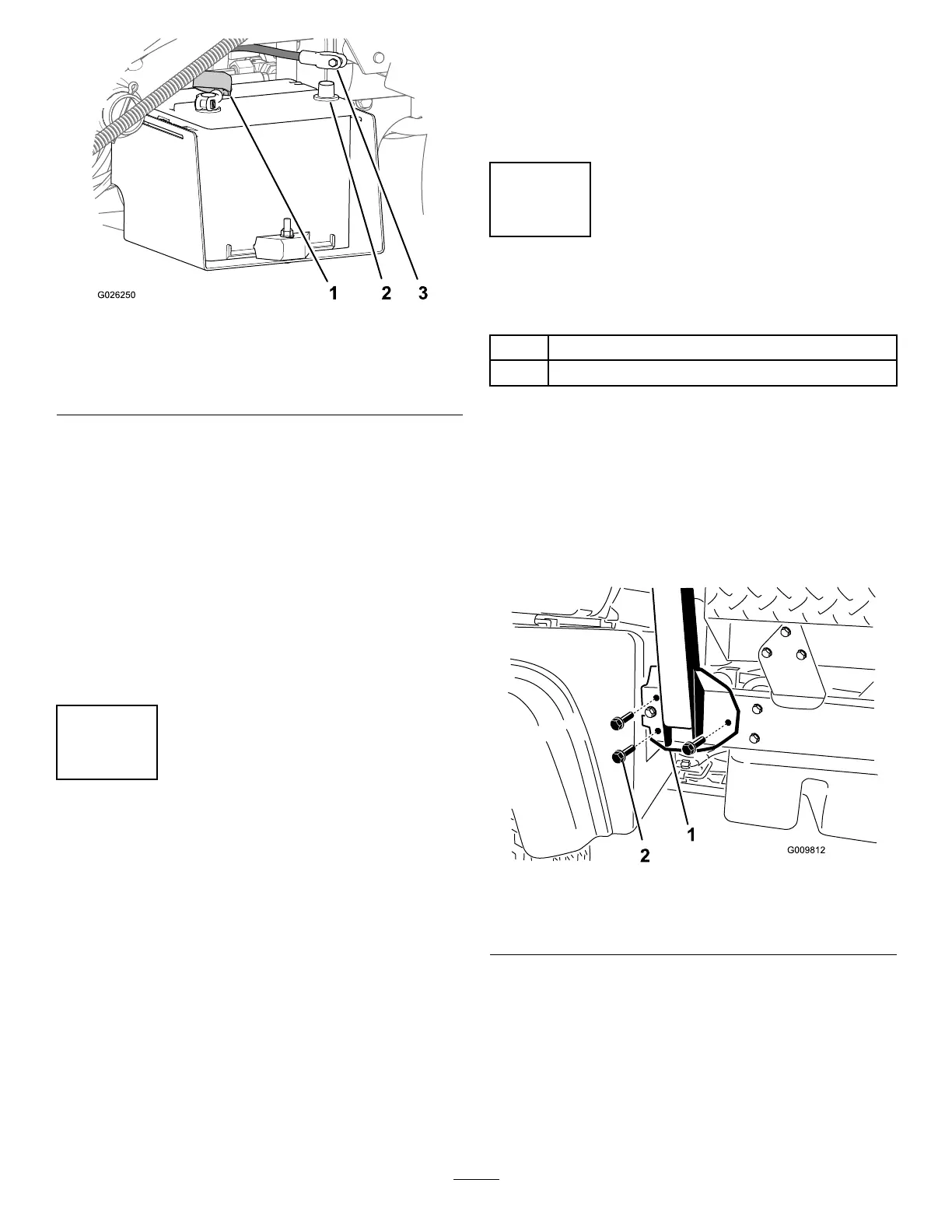

g009812

Figure6

1.Rollbarmountingbracket

2.Flange-headbolt(1/2x

1-1/4inches)

3.Securetherollbarmountingbrackettothe

machineframeusing3ange-headbolts(1/2x

1-1/4inches)oneachside(Figure6).

4.Torquetheange-headbolts(1/2x1-1/4inches)

to115N∙m(85ft-lb).

13

Loading...

Loading...