Maintenance

MaintenanceSafety

•Donotallowuntrainedpersonneltoservicethe

machine.

•Beforeyouleavetheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–ShiftthetransmissiontotheNEUTRALposition.

–Engagetheparkingbrake.

–Lowerthecargobed.

–Shutoffthemachineandremovethekey(if

equipped).

–Waitforallmovementtostop

•Allowthemachinetocoolbeforeadjusting,

servicing,cleaning,orstoringit.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Donotworkunderaraisedbedwithouttheproper

bedsafetysupportinplace.

•Ensurethatallhydraulic-lineconnectorsaretight

andthatallthehydraulichosesandlinesarein

goodconditionbeforeapplyingpressuretothe

system.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,relieveallpressureinthe

systembyshuttingoffthemotor,cyclingthedump

valvefromraisetolower,and/orloweringthecargo

bedandattachments.Placetheremotehydraulics

leverintheoatposition.Ifthebedmustbein

raisedposition,secureitwiththesafetysupport.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Donotchargethebatterieswhileservicingthe

machine.

•Toensurethattheentiremachineisingood

condition,keepallhardwareproperlytightened.

•Toreducethepotentialrehazard,keepthe

machineareafreeofexcessivegrease,grass,

leaves,andaccumulationofdirt.

•Ifpossible,donotperformmaintenancewhilethe

machineisrunning.Keepawayfrommovingparts.

•Ifyoumustrunthemachinetoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofthebodyawayfrom

anymovingparts.Keepbystandersawayfrom

themachine.

•Cleanupoilandfuelspills.

•Checktheparkingbrakeoperationas

recommendedinthemaintenancescheduleand

adjustandserviceitasrequired.

•Keepallpartsofthemachineingoodworking

conditionandallthehardwareproperlytightened.

Replaceallwornordamageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.

•Donotoverspeedtheenginebychangingthe

governorsettings.Toensuresafetyandaccuracy,

haveanAuthorizedServiceDealercheckthe

maximumenginespeedwithatachometer.

•Ifmajorrepairsareevernecessaryorassistance

isrequired,contactanAuthorizedServiceDealer.

•Alteringthismachineinanymannermayaffectthe

operationofthemachine,performance,durability,

oritsusemayresultininjuryordeath.Suchuse

couldvoidtheproductwarrantyofTheT oro®

Company.

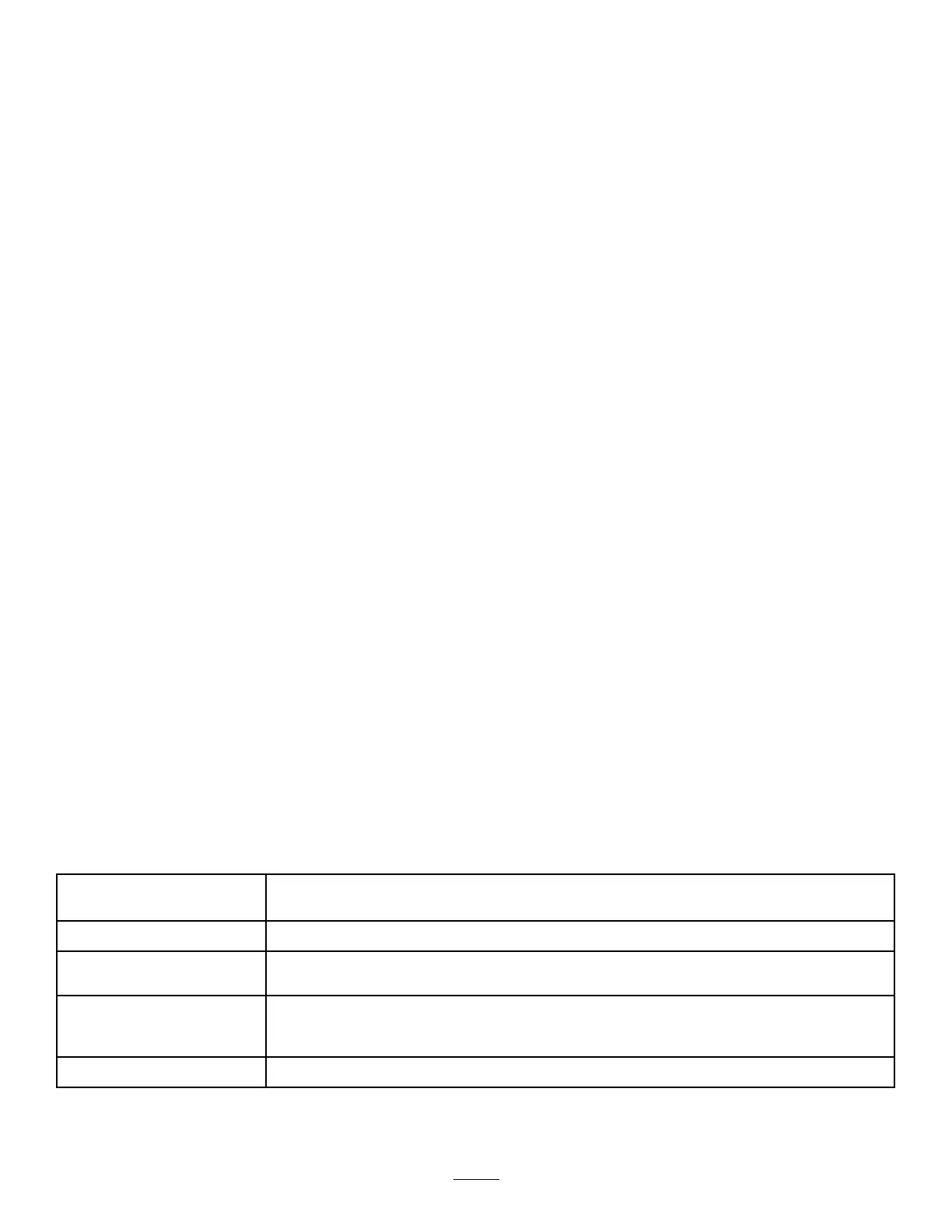

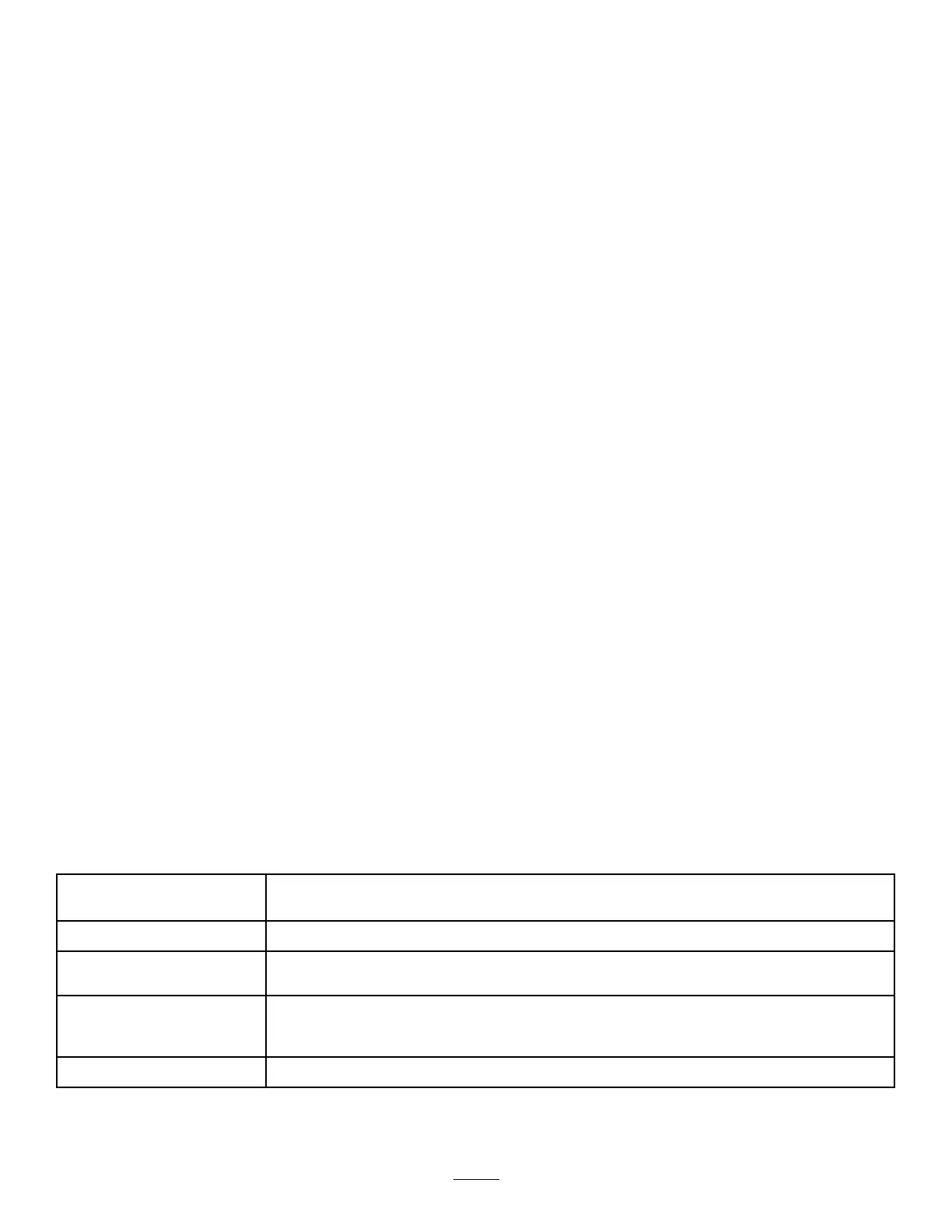

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst2hours

•Torquethefrontandrearwheelnuts.

Aftertherst10hours

•Torquethefrontandrearwheelnuts.

•Checktheadjustmentoftheparkingbrake.

Aftertherst50hours

•Changetheengineoilandlter.

•Inspecttheopeningonthelter.

•Checkthetransmission-uidlevel.

Aftertherst100hours

•Performtheguidelinesforbreakinginanewmachine.

32

Loading...

Loading...