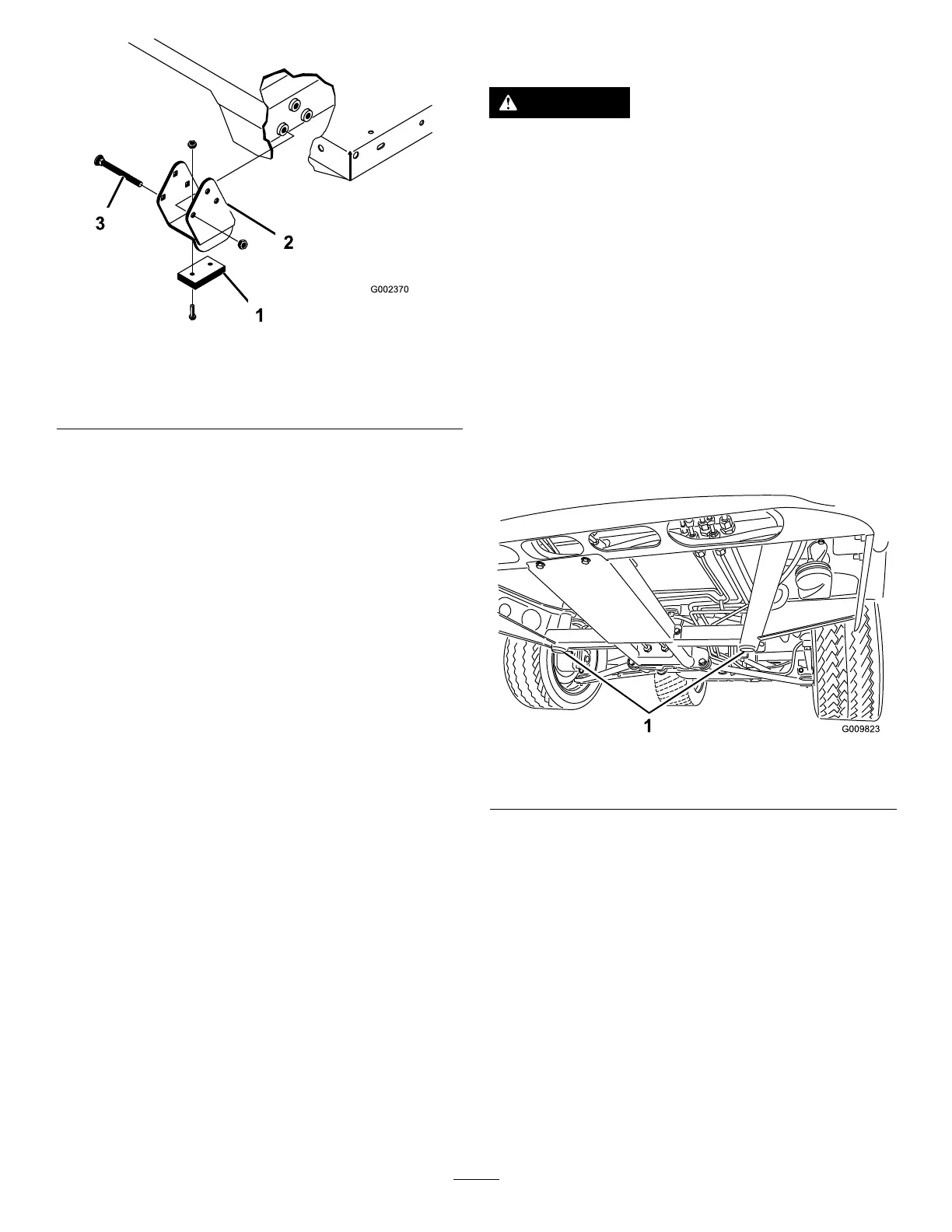

g002370

Figure32

1.Wearblock

3.Carriagebolt

2.Spacerbracket

1.Ensurethattheliftcylindersarefullyretracted.

2.Carefullysetthebedontothemachineframe,

aligningtherearbedpivot-plateholeswiththe

holesintherearframechannel,andinstallthe2

clevispinsandlynchpins(Figure32).

3.Withthebedlowered,secureeachcylinderrod

endtotheappropriateslotsinthebed-mounting

plateswithaclevispinandlynchpin.

4.Inserttheclevispinfromoutsideofthebedwith

thelynchpinorientedtowardtheoutside(Figure

32).

Note:Therearslotsareforafullbed

installation;thefrontslotsarefora2/3-fullbed

installation.

Note:Youmayneedtostarttheengineto

extendorretractthecylindersforalignmentwith

theholes.

Note:Youcanplugtheunusedslotwithabolt

andnuttopreventassemblyerrors.

5.Starttheengineandengagethehydraulic-lift

levertoraisethebed.

6.Releasetheliftleverandshutofftheengine.

7.Installthebed-safetysupporttoprevent

accidentallyloweringthebed;refertoUsingthe

BedSupport(page35).

8.Installthelynchpinstotheinsideendsofthe

clevispins.

Note:Iftheautomatictailgatereleaseis

installedonthebed,ensurethatthefrontdump

linkrodisplacedontheinsideoftheleftclevis

pinbeforeyouinstallthelynchpin.

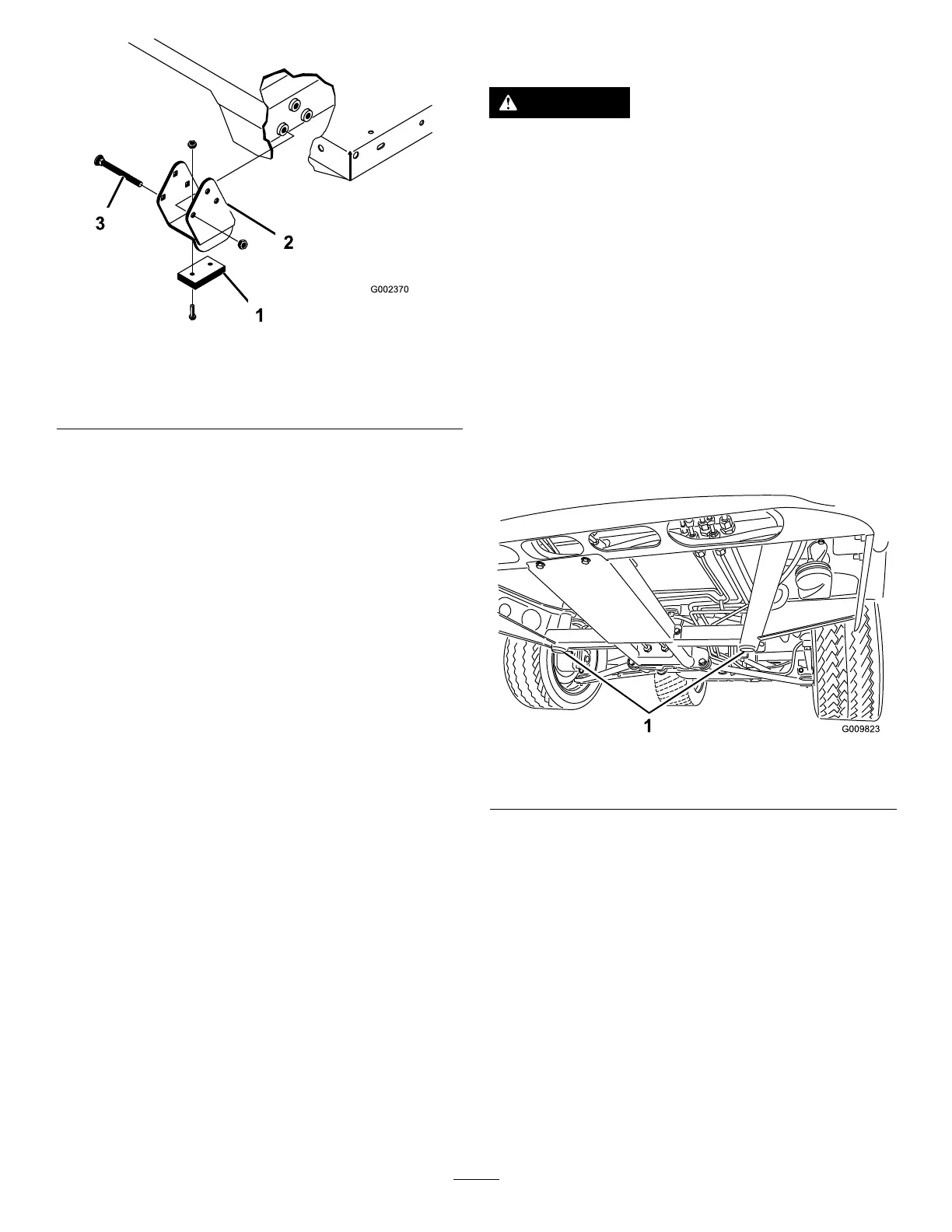

RaisingtheMachine

DANGER

Amachineonajackmaybeunstableandslip

offthejack,injuringanyonebeneathit.

•Donotstartthemachinewhilethemachine

isonajack,astheenginevibrationor

wheelmovementcouldcausethemachine

toslipoffthejack.

•Alwaysremovethekeyfromthekeyswitch

beforegettingoffthemachine.

•Blockthetireswhenthemachineisona

jack.

Whenjackingupthefrontofthemachine,always

placeawoodenblock(orsimilarmaterial)between

thejackandthemachineframe.

Thejackingpointatthefrontofthemachineislocated

underthefront,centerframesupport(Figure33).

g009823

Figure33

1.Frontjackingpoints

Thejackingpointattherearofthemachineislocated

undertheaxle(Figure34).

37

Loading...

Loading...